Method for integrating multiple kinds of waste heat for coupled heat supply

A waste heat and waste heat recovery technology, applied in hot water central heating systems, heating methods, central heating components, etc., can solve problems such as abandonment, reduce consumption, reduce heating costs, and increase power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

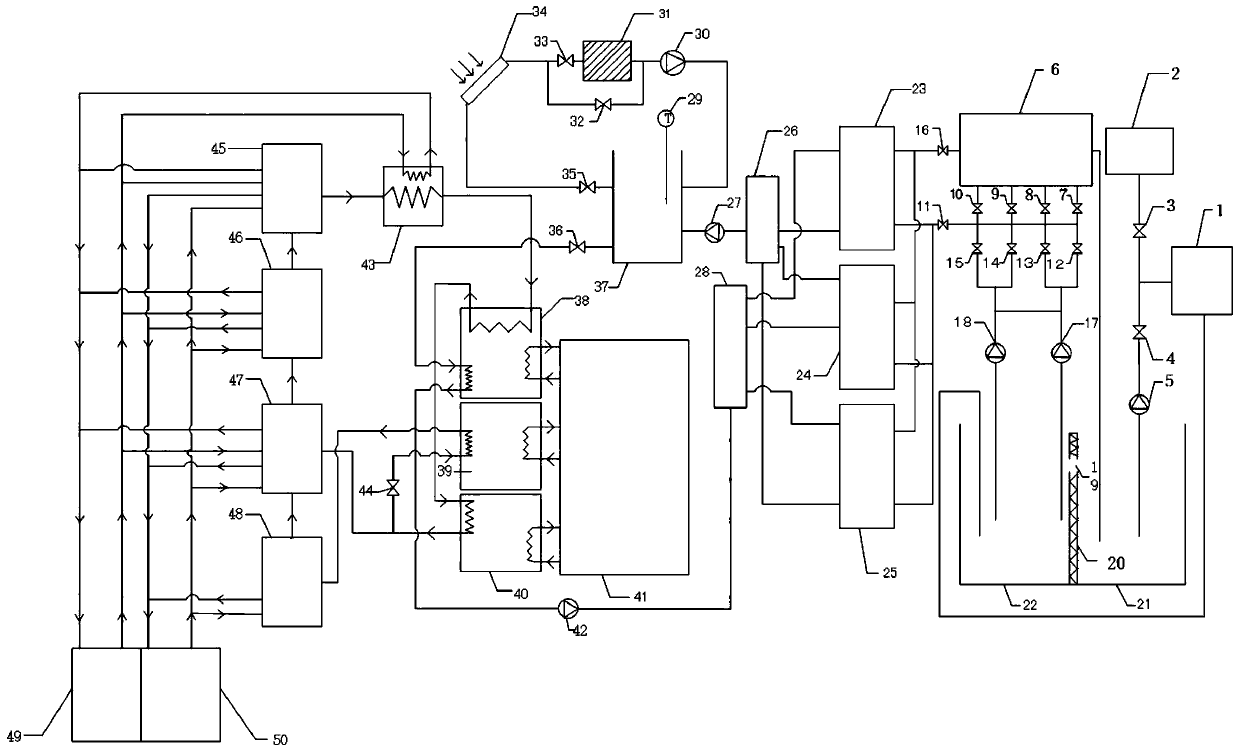

[0016] A heating system integrating multiple waste heat couplings, including a float glass waste heat recovery device, a solar waste heat recovery device and a lithium bromide heat pump heating device.

[0017] The float glass waste heat recovery device includes a float glass workshop (1), a heat pool (22), a cold pool (21), a second circulation pump (17), a two-stage control valve, a cooling tower (6), a heat pump , the first water outlet of the float glass workshop (1) is passed into the hot pool (22) by the first water pipe, the inlet of the cooling tower (6) is connected with the upper water pipe, and the outlet pipeline of the cooling tower (6) is passed into the cold pool ( 21), the upper water pipe is equipped with a two-stage control valve and a circulation pump, the upper water pipe leads to the heat pool (22), and the circulation pump is arranged at the position between the heat pool (22) and the two-stage control valve on the upper water pipe, the two-stage The valv...

Embodiment 2

[0051] A power plant waste heat, solar energy, and float glass waste heat coupling heating system. The whole system is composed of a float glass waste heat recovery device, a solar waste heat recovery device, and a lithium bromide heat pump heating device.

[0052]The main working principle of the float glass waste heat recovery device is: when the waste heat recovery is carried out in winter, the 37-39 ℃ circulating water containing a large amount of low-temperature waste heat generated by the float glass workshop 1 is discharged into the heat pool 22, and the third circulating pump 18. Pressurize the second circulation pump 17, open the eighth control valve 12, the ninth control valve 13, the tenth control valve 14, the eleventh control valve 15, and close the third control valve 7 and the fourth control valve 8 , the fifth control valve 9, the sixth control valve 10; these circulating water are introduced into the first heat pump 23, the second heat pump 24, and the third he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com