Positive electrode material and preparation method thereof, positive electrode plate, battery cell and battery

A technology of positive electrode materials and positive electrode sheets, which is applied in the direction of batteries, battery electrodes, secondary batteries, etc., can solve problems such as poor withstand voltage performance and affect battery cycle stability, so as to improve the withstand voltage performance, improve the withstand voltage performance and The effects of cycle stability and good withstand voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

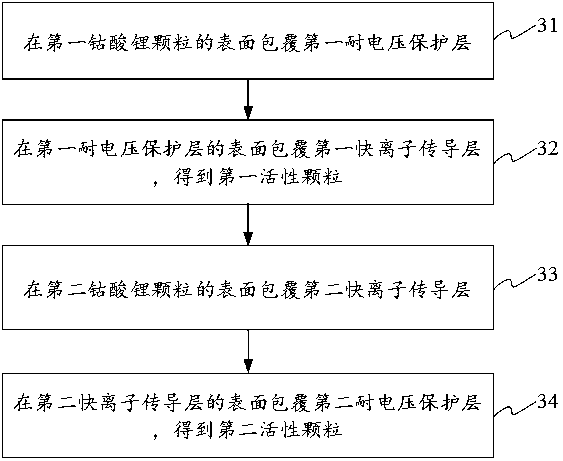

[0071] image 3 Shown is a flowchart of a method for preparing a positive electrode material according to an exemplary embodiment of the present disclosure. Some embodiments of the present disclosure also provide a method for preparing a positive electrode material, which is used to prepare any of the above-mentioned positive electrode materials, refer to image 3 , the preparation method comprises:

[0072] Step 31, coating the surface of the first lithium cobaltate particles with a first withstand voltage protection layer.

[0073] In some embodiments, step 31 includes:

[0074] Mixing the first lithium cobaltate particles and the first withstand voltage protecting agent, so that the first withstand voltage protecting agent is coated on the surface of the first lithium cobaltate particles, and then performing the first sintering treatment, the first crushing treatment and the second A separation treatment, the first voltage-resistant protection agent forms a first voltage...

Embodiment 1

[0105] This embodiment provides a positive electrode material, including first active particles and second active particles. The first active particle is doped with magnesium oxide with a mass fraction of 2000ppm, and the first active particle is sequentially covered with an aluminum oxide layer with a mass fraction of 800ppm and a titanium oxide layer with a mass fraction of 1000ppm from the inside to the outside. The second active particle is doped with magnesium oxide with a mass fraction of 2500ppm, and the second active particle is coated with a titanium oxide layer with a mass fraction of 600ppm and an aluminum oxide layer with a mass fraction of 1200ppm sequentially from the inside to the outside.

Embodiment 2

[0107] This embodiment provides a positive electrode material, including first active particles and second active particles. The first active particle is doped with magnesium oxide with a mass fraction of 2000ppm, and the first active particle is sequentially covered with an aluminum oxide layer with a mass fraction of 800ppm and a titanium oxide layer with a mass fraction of 1000ppm from the inside to the outside. The second active particle is doped with magnesium oxide with a mass fraction of 3000 ppm, and the second active particle is coated with a titanium oxide layer with a mass fraction of 400 ppm and an aluminum oxide layer with a mass fraction of 1500 ppm from the inside to the outside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size range | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com