Preparation method of composite solid electrolyte and application of composite solid electrolyte in solid-state lithium ion battery

A solid electrolyte and lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as poor flexibility, poor mechanical properties, and low electrical conductivity, and achieve improved cycle stability and strong mechanical properties , the effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

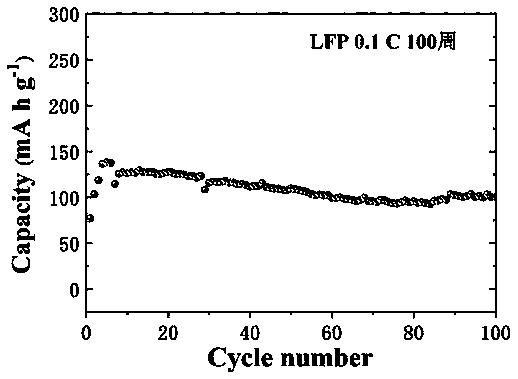

Embodiment 1

[0023] The polymer PEO, lithium salt LiTFSI, PET fiber material and solvent acetonitrile are prepared into a solution according to the mass ratio of 2:1:0.2:20 and stirred overnight, and then the uniformly mixed solution is formed into a film on the substrate and dried A solid electrolyte membrane is produced. The positive electrode is lithium iron phosphate, ternary and other commonly used positive electrode materials. Lithium, graphite, silicon carbon and other commonly used negative electrodes are selected as the negative electrode. The solid electrolyte membrane after vacuum drying at 60°C was placed between the positive pole piece and the negative pole piece and pressed to obtain a solid lithium ion battery.

Embodiment 2

[0025] The polymer PPC, lithium salt LiTFSI, PET fiber material and solvent acetonitrile are formulated into a solution according to the mass ratio of 2:1:0.2:20 and stirred overnight, and then the uniformly mixed solution is formed into a film on the substrate and dried A solid-state electrolyte membrane was prepared, and the fabrication of the solid-state lithium-ion battery was the same as in Example 1.

Embodiment 3

[0027] Polymer PEO, lithium salt LiTFSI, PET fiber material, ionic liquid 1-hexyl-3-picoline bistrifluoromethanesulfonimide salt and solvent acetonitrile are 2:1:0.2:2:20 according to the mass ratio The ratio is prepared into a solution and stirred overnight, and then the uniformly mixed solution is formed into a film on a substrate and dried to obtain a solid electrolyte membrane. The manufacturing part of the solid-state lithium-ion battery is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com