Ti-based MOF composite material, and preparation method and application thereof

A composite material, diethylaniline technology, applied in chemical instruments and methods, catalyst activation/preparation, water treatment of special compounds, etc., can solve the problems of high energy consumption, damage to the original material structure, etc., to increase the number of photogenerated electrons, The preparation method is simple and safe, and the effect of good recovery and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] MR / NH 2 -The preparation method of MIL-125 composite material, comprising steps:

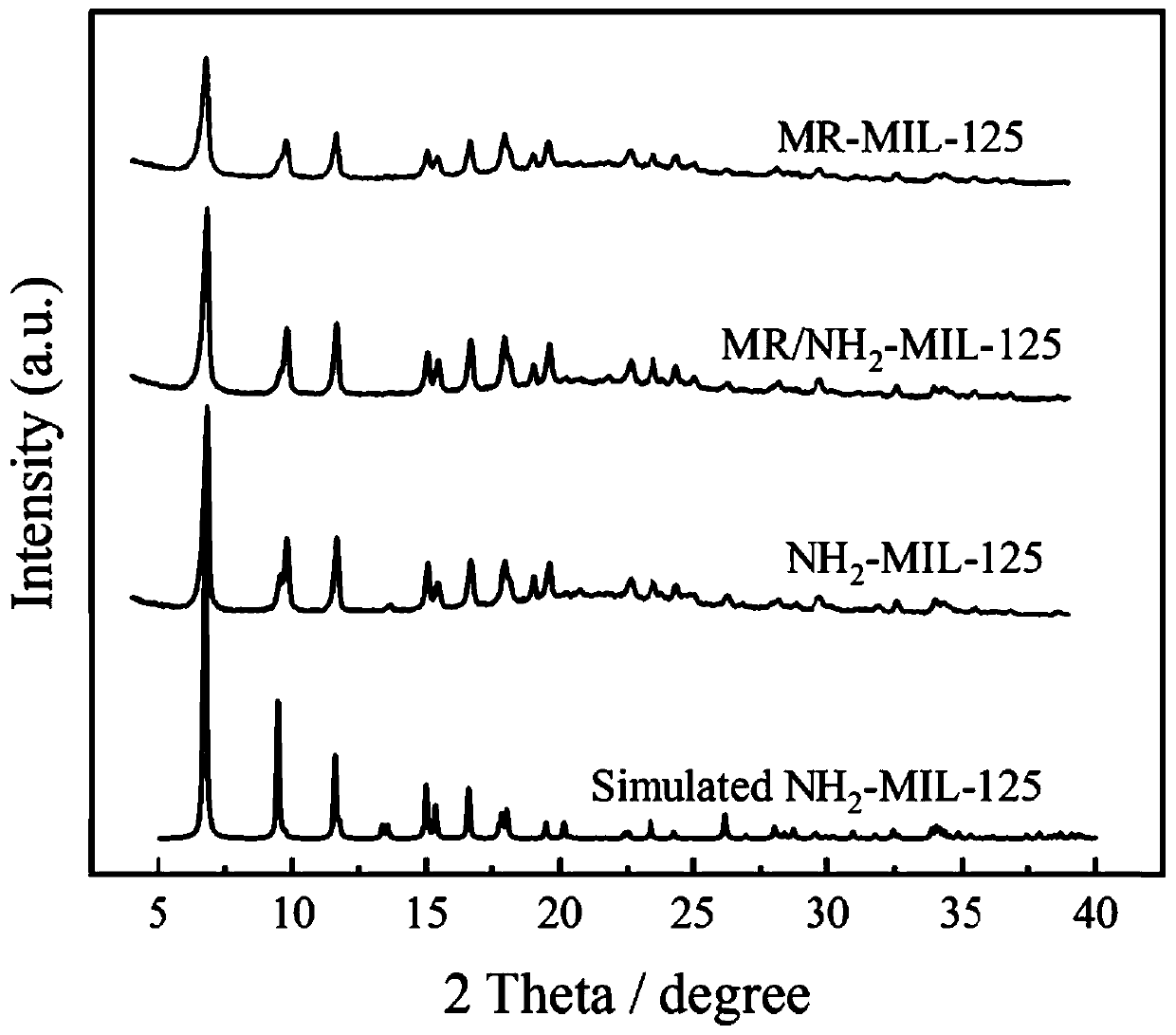

[0052] (1) Dissolve 3.85 g of 2-aminoterephthalic acid (ATA) and 4.2 mL of butyl titanate in 14 mL of anhydrous methanol and 56 mL of anhydrous N,N-dimethylformamide (DMF) in a round bottom flask Mix the solution, use a reflux condenser, heat and stir, keep the solution temperature at 100°C and reflux for 72h, cool to room temperature and filter the mixture, separate the solid, wash with DMF at 155°C for 24h, then wash with methanol at 100°C, the product Dry in air at 100 °C and triturate to give NH 2 - MIL-125(Ti) powder.

[0053] (2) 200mg NH 2 -MIL-125(Ti) suspended in 90mL water to form a suspension, 22.75mg NaNO 2 (330μmol, NH 2 -MIL-125(Ti) with NaNO 2 The molar ratio is 1:3) dissolved in the above MOF aqueous suspension. The temperature was cooled in an ice-water bath and kept at 0°C, and the stirring was continued. 60 mL of 0.03M HCl was added dropwise, and the stirring was...

Embodiment 2

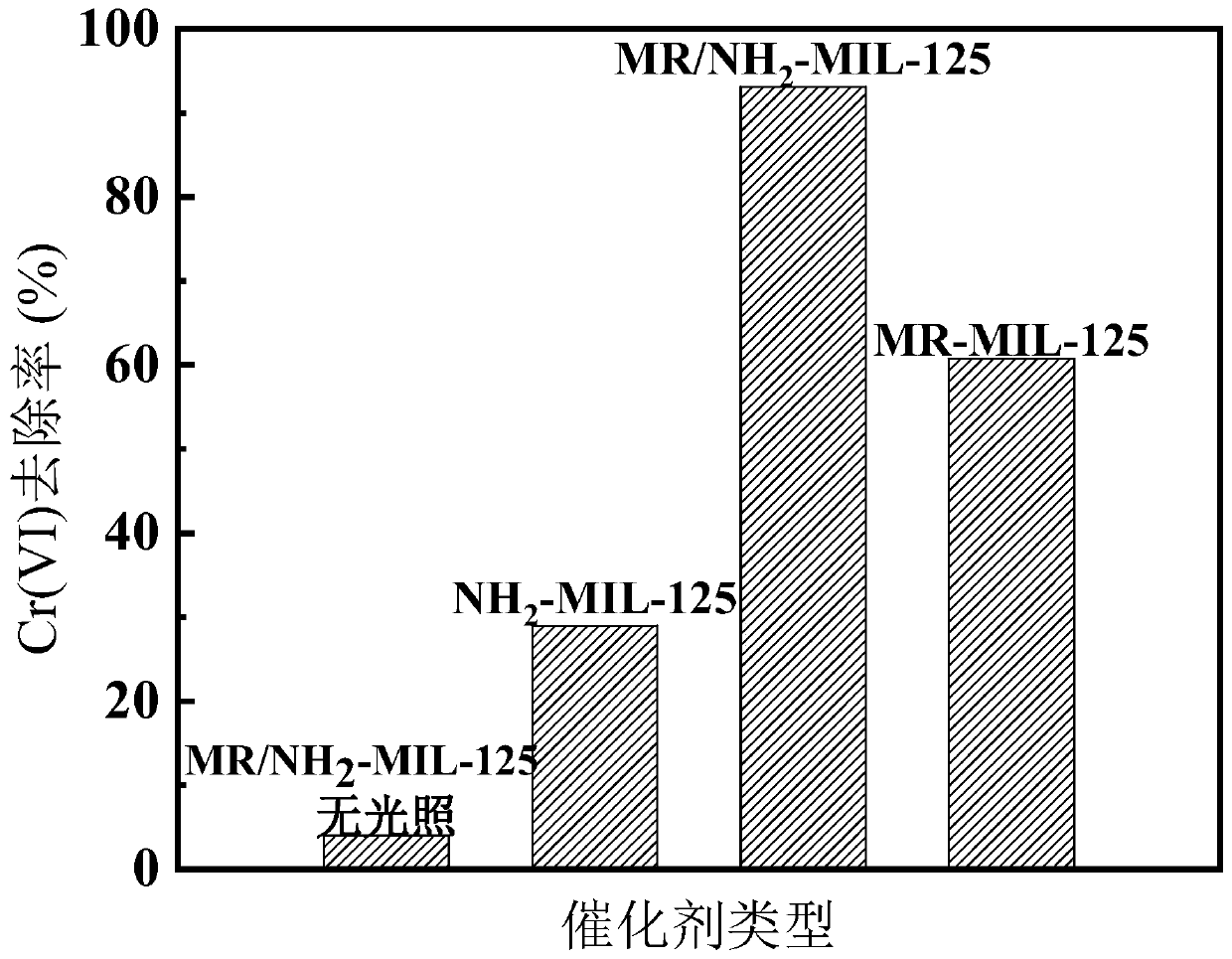

[0058] Taking the reduction of chromium-containing Cr(VI) waste water as an example to test the single NH of embodiment 1 2 -MIL-125(Ti), MR / NH 2 The catalytic activity of -MIL-125 composite catalyst and single MR-MIL-125 (Ti), in the chromium-containing Cr (VI) wastewater that adding volume is 100mL, concentration is 80 μ mol / L in the reactor, adds 10mg above-mentioned catalyst, Add EDTA-2Na at a concentration of 2mmol / L as a hole-scavenging agent for synergistic reaction, adjust pH=2, continue to stir, stir in the dark for 30min to adsorption equilibrium, turn on the visible light source, and carry out photocatalytic reaction for 120min.

[0059] Such as figure 2 , the MR / NH prepared in this example 2 -MIL-125 composite photocatalyst is superior to single NH 2 - MIL-125(Ti) catalyst, single MR-MIL-125(Ti), has the best visible light reduction effect of Cr(VI).

Embodiment 3

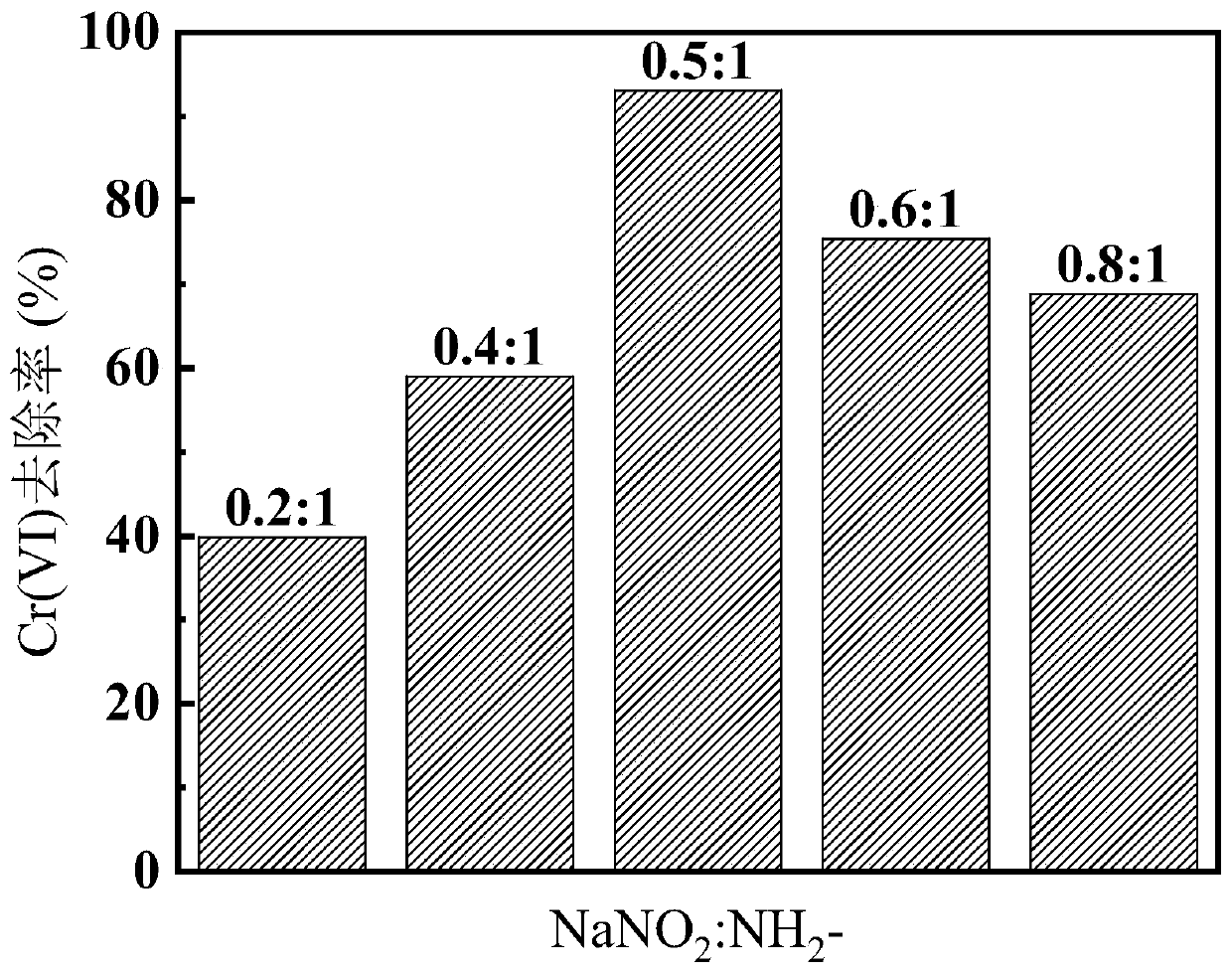

[0061] According to the preparation method of Example 1 steps (1)~(3), different amounts of nitrite NaNO were added during the preparation process 2 , can change NH 2-The ratio of diazotization reaction of MIL-125(Ti) to form MR / NH with different diazotization ratios 2 - MIL-125 composite catalyst. Add 9.1, 18.2, 22.75, 27.3, 36.4 mg NaNO respectively in the synthesis step (2) of Example 1 2 , making NaNO 2 with NH 2 -Amino group on MIL-125 (Ti) (according to 1mol NH 2 The molar ratios of the amino groups on MIL-125 (Ti) are 6 mol) are 0.2:1, 0.4:1, 0.5:1, 0.6:1, and 0.8:1, respectively.

[0062] Such as image 3 , MR / NH with different diazotization ratios prepared in this example 2 -Add NaNO to MIL-125 composite catalyst 2 When the molar ratio to amino group is 0.5:1, it has the best effect of reducing Cr(VI) with visible light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com