Polyarylethersulfone with side chain type aromatic main chain embedded with aliphatic chain, preparation method for polyarylethersulfone, and homogeneous anion exchange membrane

A polyarylethersulfone and aliphatic chain technology, applied in the field of homogeneous anion exchange membranes, can solve the problems of shortening the effective service life of the membrane, increasing the energy consumption of the separation process, and increasing the surface resistance of the membrane, achieving good chemical stability and mechanical properties , long-term stability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0055] Synthesis of 1,3-bis(4-hydroxyphenoxy)propane: In a 500mL three-necked round-bottomed flask, add hydroquinone (20mmol) and 1,3-dibromopropane (5mmol), and dissolve in 250mL anhydrous Ethanol was used as a solvent, and 0.2 g of sodium hydroxide was added as a hydrogen extraction agent. in N 2 Under the atmosphere, react at 80°C for 6h, then cool to room temperature, pour the reaction mixture into 1L of pure water, filter with suction to obtain a white solid, wash with pure water three times, dry in vacuum at 40°C for 24h, and then dry in vacuum at 60°C for 48h to obtain 1,3 - Bis(4-hydroxyphenoxy)propane, 95% yield.

[0056] Synthesis of 1-methyl-3-(3-bromopropane)-imidazolium bromide: Dissolve 30mmol 1-methylimidazole and 120mmol 1,3-dibromopropane in acetone, react at 40°C for 24h, and filter the resulting suspension A clear and colorless filtrate was obtained, and the acetone was removed by rotary evaporation at 40°C, then poured into 50 mL of ether, stirred and pre...

Embodiment 1-2

[0060] Preparation of side chain type aromatic main chain embedded fatty chain polyarylethersulfone anion exchange membrane (PAES-co3C-3CIM): dissolve 2.8g of side chain type aromatic main chain embedded fatty chain polyarylethersulfone prepared in Example 1-1 In 60mL NMP solvent, magnetically stir at 80°C until completely dissolved to obtain the casting solution; defoam the casting solution, and then apply the defoamed casting solution on a clean glass plate, bake at 80°C Dry to form a film to obtain a homogeneous anion exchange membrane with a film thickness of 94 μm.

Embodiment 2-1

[0062] Synthesis of 1,6-bis(4-hydroxyphenoxy)hexane: after replacing 1,3-dibromopropane in Example 1-1 with 1,6-dibromohexane, use the same method as in Example 1 In the same preparation process, in 1,6-two (4-hydroxyphenoxy) hexane.

[0063] Synthesis of 1-methyl-3-(3-bromopropane)-imidazolium bromide: the same preparation process as in Example 1-1 was adopted.

[0064] Preparation of amino-containing polyaryl ether sulfone with aromatic main chain embedded in aliphatic chain: replace 1,3-bis(4-hydroxyphenoxy)propane in Example 1-1 with 1,6-bis(4-hydroxybenzene After oxy)hexane, adopt same preparation process among the embodiment 1-1.

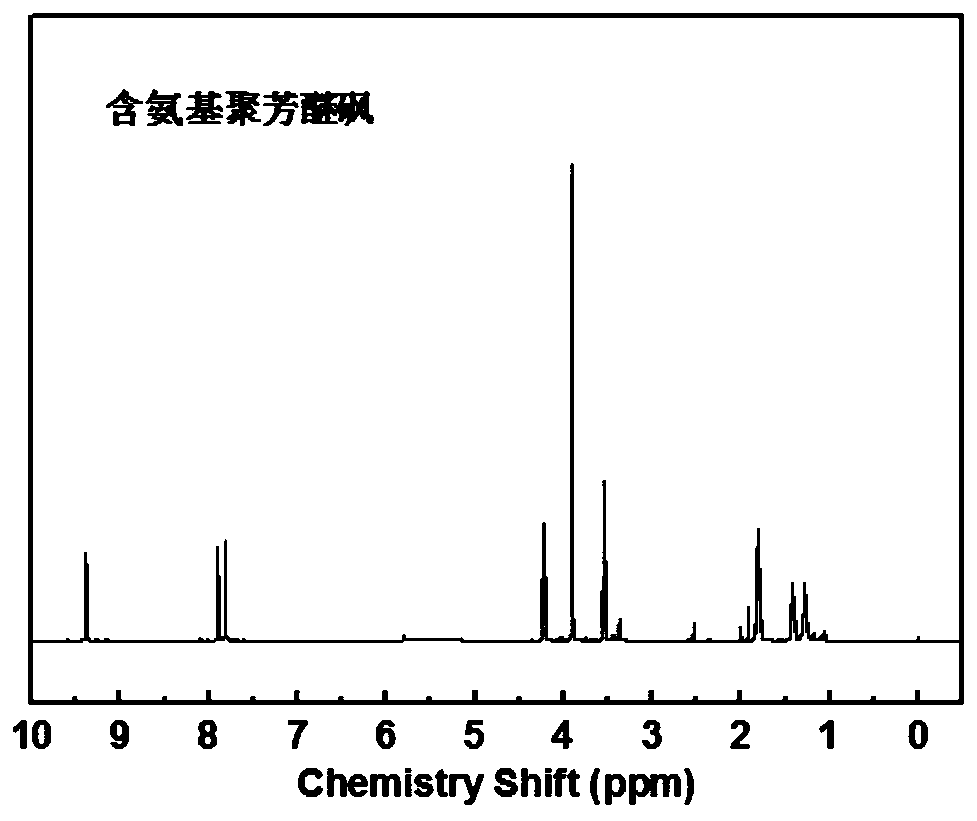

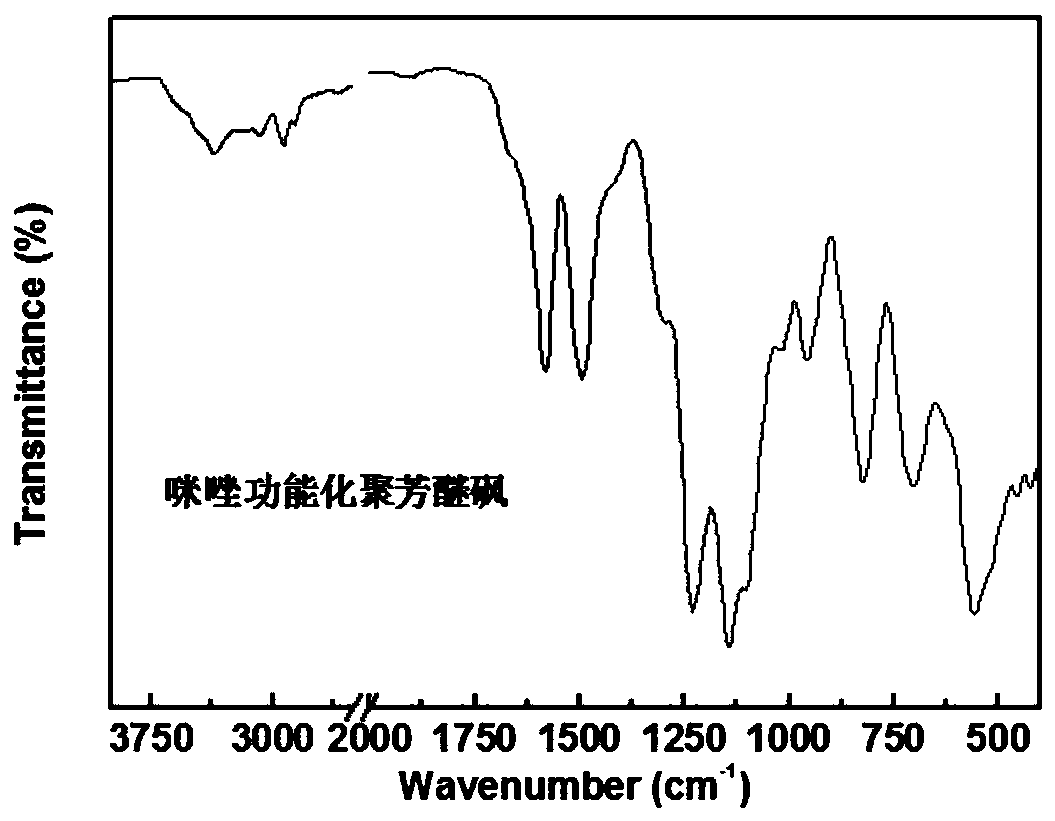

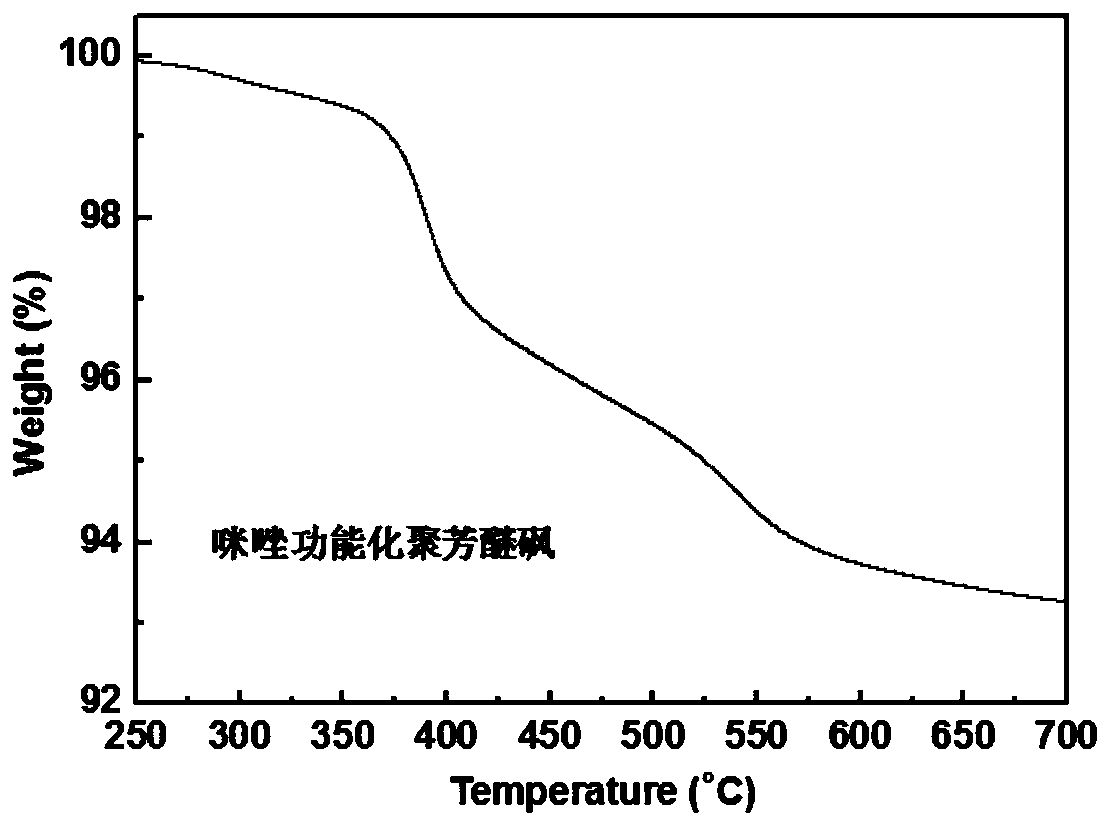

[0065] Preparation of side chain type aromatic main chain embedded fatty chain polyarylether sulfone: take 5.0 g of amino-containing polyaryl ether sulfone with aromatic main chain embedded fatty chain obtained in the previous step and 1-methyl-3-(3-bromopropane) - 7.4 g of imidazolium bromide salt, using the same preparation process as in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com