Biochar with high electron exchange capacity, and preparation method thereof

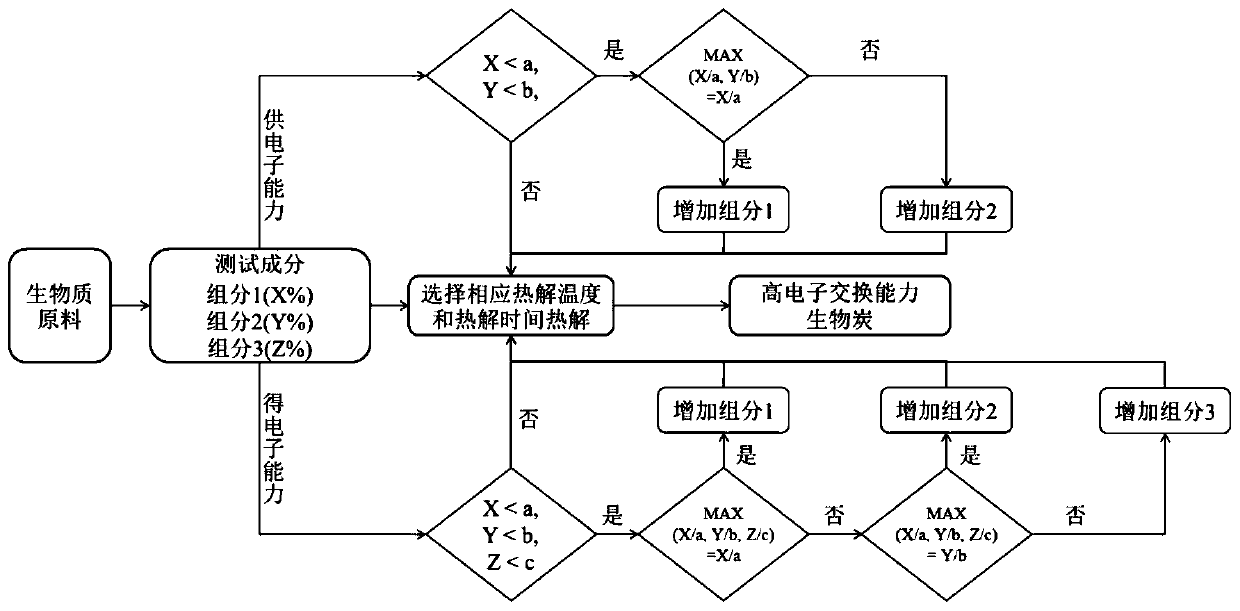

A technology of exchange capacity and biochar, applied in the fields of electron exchangers, biofuels, chemical instruments and methods, etc., can solve the problems such as no modification or activation method of electron exchange capacity, many drugs added, and complicated processes, so as to promote biological Transformation rate and microbial activity, energy saving, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

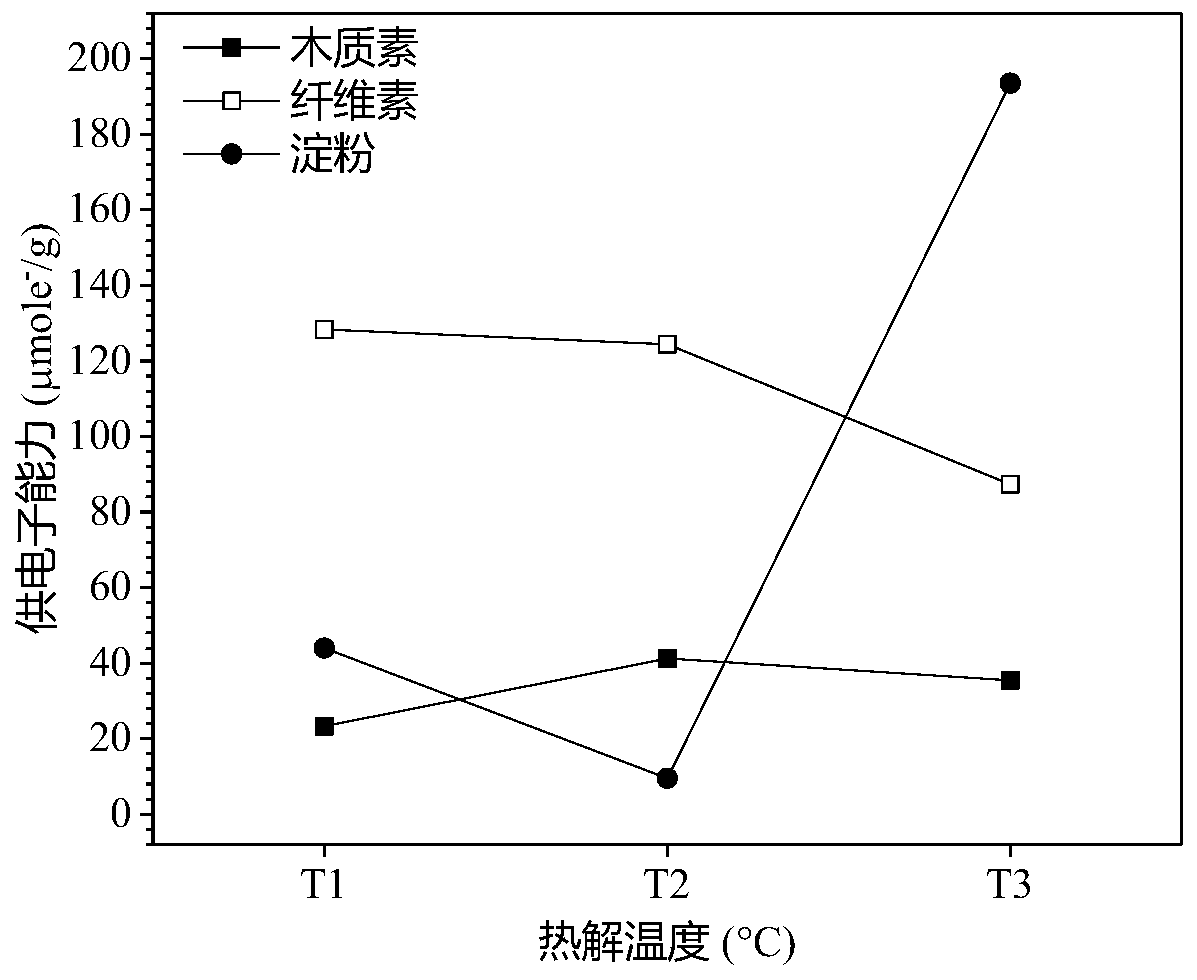

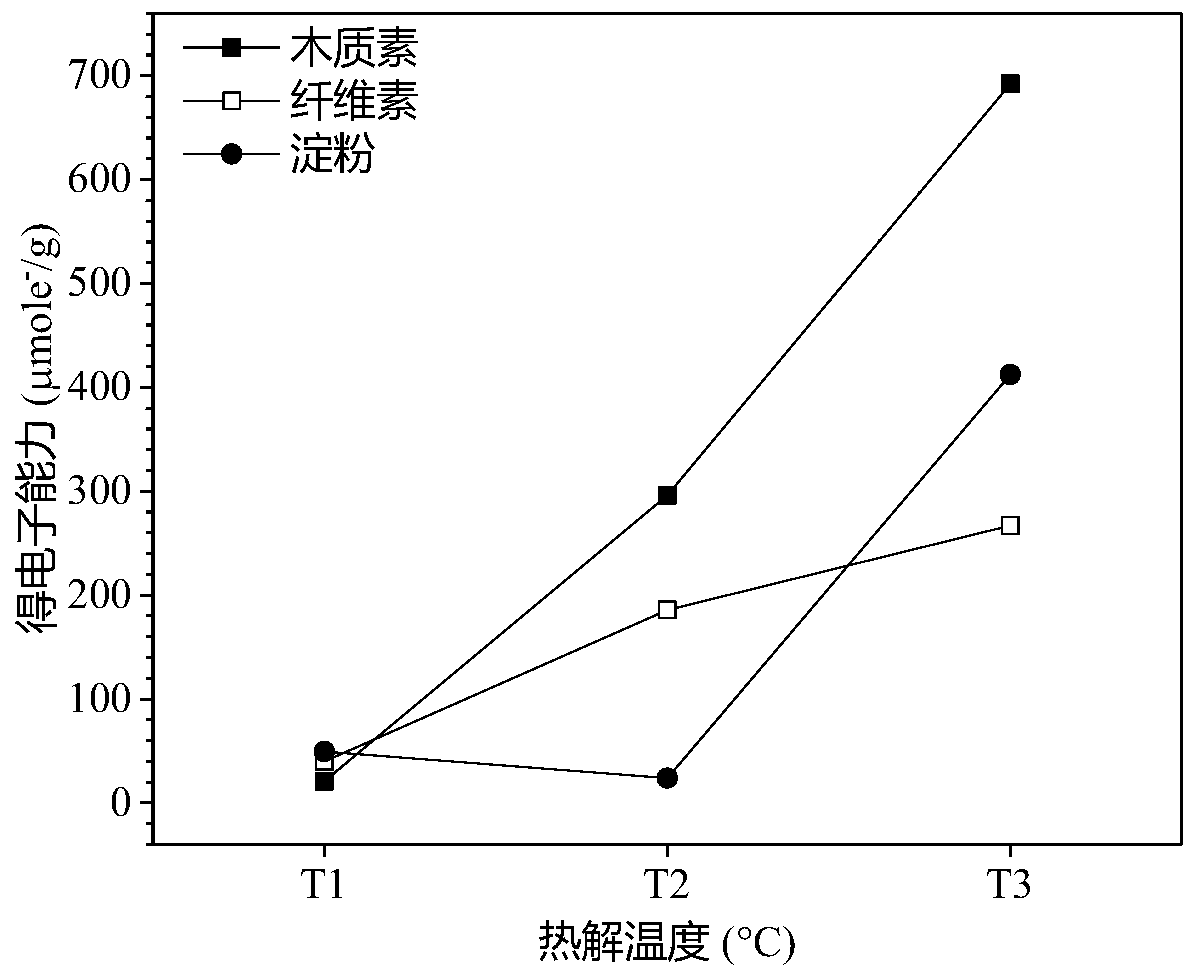

[0037] The biomass raw material to prepare biochar is a mixture of thatch grass and Mendong grass, and its biomass composition is tested: the cellulose content is 63% dw, the starch content is 0%, and the lignin content is 13% dw, which is a cellulosic biomass. substance.

[0038] If the target biochar whose electron exchange ability is electron-donating ability is directional prepared, it is not necessary to optimize the thatch grass, and the whole amount of thatch grass is directly ground and passed through a 200-mesh sieve, and fully mixed to obtain the biomass to be pyrolyzed; Biomass samples were pyrolyzed at 300°C for 1 hour, 400°C for 1 hour, and 500°C for 30 minutes. During the pyrolysis process, inert gas was continuously introduced to keep the oxygen concentration below 10ppm. After the pyrolysis was completed, the target Biochar A1, B1, C1.

[0039] If the target biochar whose electron exchange ability is the ability to obtain electrons is directional prepared, the...

Embodiment 2

[0042] The biomass raw material to prepare biochar is a mixture of potatoes and flour, and its biomass composition was tested: the starch content is 74% dw, the cellulose content is 1% dw, and the lignin content is 2%, which is starchy biomass.

[0043] If the target biochar whose electron exchange capacity is electron-donating capacity is directional prepared, there is no need to optimize the biomass raw material, and the biomass raw material is directly ground and passed through a 200-mesh sieve, and fully mixed evenly to obtain the biomass to be pyrolyzed; then The biomass sample to be pyrolyzed was pyrolyzed at 700°C for 30 minutes. During the pyrolysis process, the inert gas was continuously introduced to keep the oxygen concentration below 10 ppm. After the pyrolysis was completed, the target biochar A2 was obtained.

[0044] If the target biochar whose electron exchange capacity is the ability to obtain electrons is directional prepared, there is no need to optimize the ...

Embodiment 3

[0047] The biomass raw material to prepare biochar is pine wood, and its biomass composition was tested: the lignin content is 36% dw, the cellulose content is 30% dw, and the starch content is 0%, which is lignin biomass. The electron exchange ability of the obtained target biochar can only be the biochar with electron ability. Therefore, there is no need to optimize the pine wood, and the pine wood is directly ground and passed through a 200-mesh sieve, and fully mixed to obtain the biomass to be pyrolyzed; then three samples of the biomass to be pyrolyzed are taken and pyrolyzed at 500°C for 1 hour respectively , pyrolysis at 600°C for 1 hour, and pyrolysis at 700°C for 30 minutes. During the pyrolysis process, the inert gas was continuously introduced to keep the oxygen concentration below 10ppm. After the pyrolysis was completed, the target biochars A3, B3, and C3 were obtained respectively.

[0048] The electron exchange capacity, surface redox functional group content a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com