Method and reaction system for producing low-sulfur petroleum coke

A reaction system, petroleum coke technology, applied in the petroleum industry, hydrocarbon oil treatment, multi-stage serial refining process treatment, etc., can solve the unsuitable and unrealistic problems of separating sulfur components, and achieve the reduction of sulfur content and reduction Operating cost, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

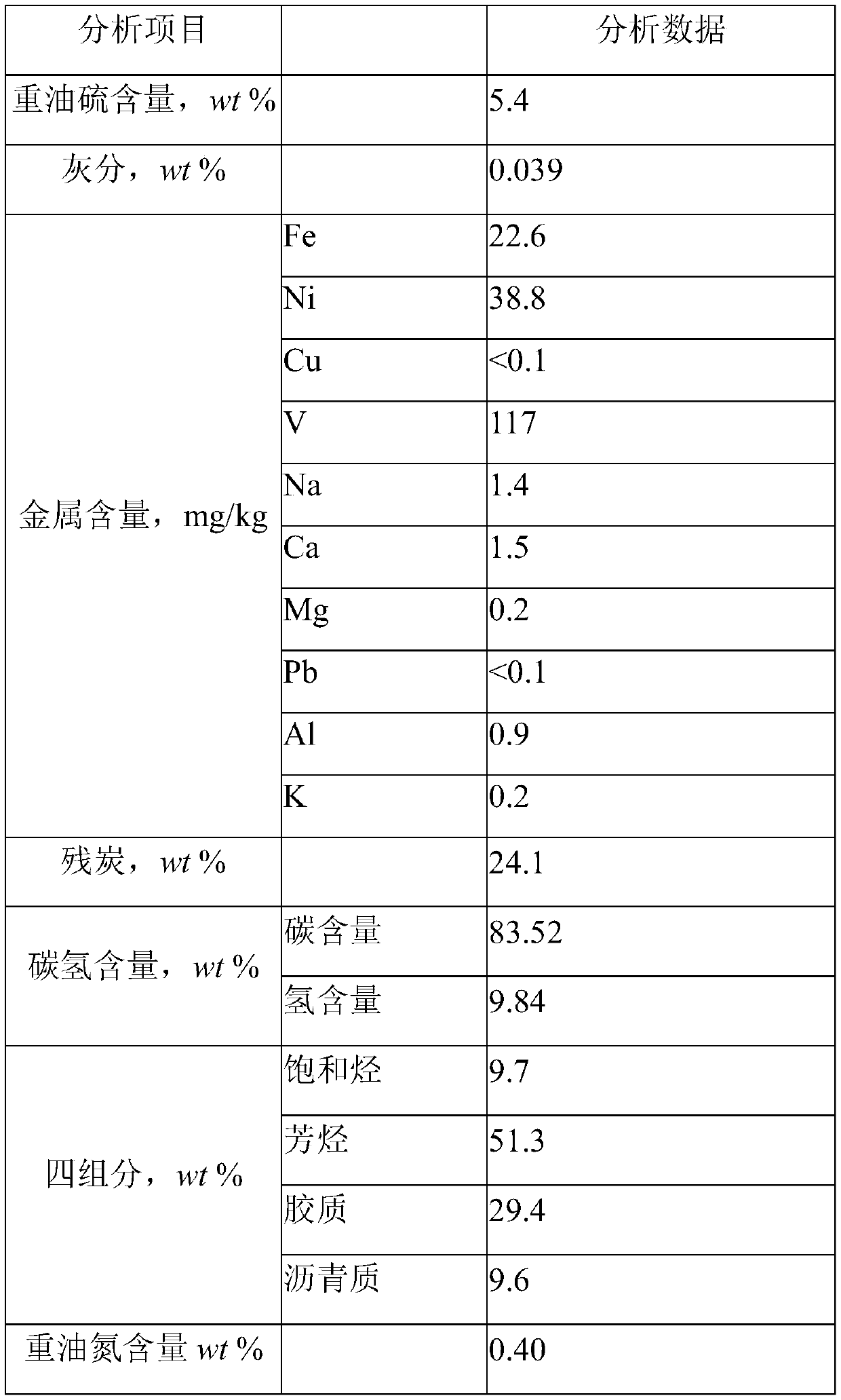

[0053] The oil-soluble catalyst is molybdenum isooctanoate purchased from the market, and the manufacturer is Xianju Fusheng Chemical Factory, which is denoted as A1, and its metal molybdenum content is 15.2 wt%.

[0054] Toluene is used as the dilution solvent, and the residual oil and toluene are diluted at a weight ratio of 1:0.7. Weigh 170g of the diluted residual oil, add 3.0g of A1 catalyst, and add 38wt% at a rate of 0.0.5g / min at 85°C Hydrogen peroxide, the molar ratio of sulfur and hydrogen peroxide in the residual oil is 1:5, and the reaction time is 1h.

[0055] The reactant is distilled to remove the solvent to obtain the oxidized residue oil Y1. The operation condition of the distillation is normal pressure and the temperature is 110° C., and the toluene and water are distilled off.

[0056] Take 2g of oxidized residual oil and conduct a rapid coking experiment to obtain petroleum coke C1. The sulfur content in the petroleum coke is analyzed. The experimental resu...

Embodiment 2

[0058] Catalyst A2 uses molybdenum isooctanoate purchased from the market, the manufacturer is Alfa Aesar, and the molybdenum content is 15.6 wt%.

[0059] Using the same experimental method as in Example 1, gasoline fractions were used as diluents. The gasoline fractions were obtained from Yanshan Petrochemical Co., Ltd., with a distillation range of 45°C-220°C. dilution. Weigh 180g of diluted residual oil, add 4.0g of A2 catalyst, and add 38wt% hydrogen peroxide at a rate of 0.0.5g / min at 85°C, so that the molar ratio of sulfur to hydrogen peroxide in the residual oil is 1: 6. The reaction time is 1h.

[0060] The reactant is distilled to remove the solvent to obtain the oxidized residue Y2. The operation condition of the distillation is normal pressure, the temperature is 230°C, and the gasoline and water are distilled off.

[0061] Take 2g of oxidized residual oil and conduct a rapid coking experiment to obtain petroleum coke C2. The sulfur content in the petroleum coke ...

Embodiment 3

[0063] Catalyst A3 is iron isooctanoate purchased from the market, produced by Xianju Fusheng Chemical Plant, and its metallic iron content is 13.4 wt%.

[0064] The experimental method is the same as in Example 1. The diluent is diluent using catalytic diesel fraction (taken from Yanshan Petrochemical Co., Ltd., with a distillation range of 220°C-320°C), and diluting residual oil raw material and diesel fraction at a weight ratio of 1:1. Weigh 200g of diluted residual oil, add 4.4g of A3 catalyst, and add 38wt% hydrogen peroxide at a rate of 0.0.5g / min at 85°C, so that the molar ratio of sulfur to hydrogen peroxide in the residual oil is 1: 3. The reaction time is 1h.

[0065] The reactant is distilled to remove the solvent to obtain the oxidized residue Y3. The distillation operating condition is normal pressure and the temperature is 330° C. to distill diesel oil and water.

[0066] Take 2g of oxidized residual oil and conduct a rapid coking experiment to obtain petroleum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com