Gallium nitride power device with multi-field plate structure, and preparation method thereof

A technology of power devices and gallium nitride, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as limited effects, device performance degradation, and serious reliability of traditional devices, so as to achieve enhanced withstand voltage, Effects of improving reliability and suppressing current collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

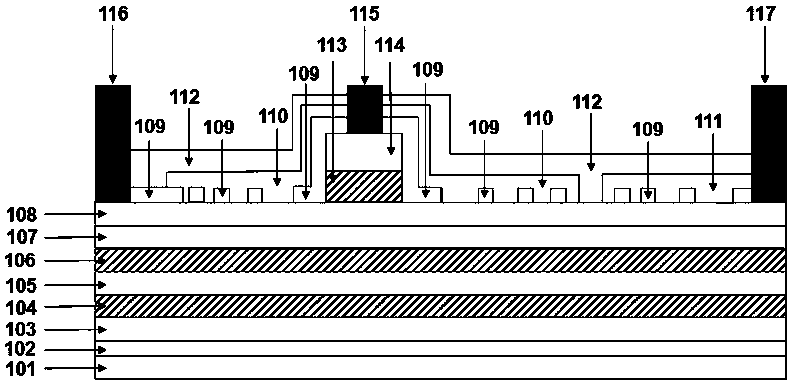

[0047] Example 1, such as figure 1 As shown, a GaN power device with high reliability involved in this embodiment includes a silicon substrate 101 arranged in sequence from bottom to top, an AlN nucleation layer 102 with a thickness of 5 nm, a GaN buffer layer 103 with a thickness of 1000 nm, The GaN / AlInN first insertion layer 104 has a period number of 5 and a thickness of 50nm; the first GaN layer 105 has a thickness of 1000nm; the AlN second insertion layer 106 has a thickness of 10nm; 5nm thick, SiO 2 Passivation layer 109 with a thickness of 20nm, titanium / aluminum / nickel / gold gate field plate 110, titanium / aluminum / nickel / gold drain field plate 111, Si 3 N 4 The protective layer 112 has a thickness of 200 nm, and the p-type doping concentration of the GaN / AlInGaN gate insertion layer 113 is: 1×10 16 cm -3 , the number of periods is 1, the thickness is 5nm, and the doping concentration of the p-type GaN gate 114 is: 1×10 16 cm -3 , with a thickness of 30 nm, titani...

Embodiment 2

[0071] Example 2, such as figure 1As shown, a GaN power device with high reliability involved in this embodiment includes a silicon substrate 101 arranged in sequence from bottom to top, an AlN nucleation layer 102 with a thickness of 15 nm, a GaN buffer layer 103 with a thickness of 1500 nm, The GaN / AlInN first insertion layer 104 has a period number of 15 and a thickness of 400nm, the first GaN layer 105 has a thickness of 1500nm, the AlN second insertion layer 106 has a thickness of 70nm, the second GaN layer 107 has a thickness of 1500nm, and the AlGaN barrier layer 108 Thickness 35nm, SiO 2 Passivation layer 109 with a thickness of 150nm, titanium / aluminum / nickel / gold gate field plate 110, titanium / aluminum / nickel / gold drain field plate 111, Si 3 N 4 The protective layer 112 has a thickness of 1500 nm, and the p-type doping concentration of the GaN / AlInGaN gate insertion layer 113 is: 1×10 18 cm -3 , the number of periods is 3, the thickness is 35nm, and the doping co...

Embodiment 3

[0077] Embodiment 3, a gallium nitride power device with high reliability involved in this embodiment, including a sapphire substrate arranged in sequence from bottom to top, an AlN nucleation layer with a thickness of 20nm, a GaN buffer The thickness of the layer is 3000nm, the period number of the first GaN / AlInGaN insertion layer is 20, the thickness is 500nm, the thickness of the first GaN layer is 3000nm, the thickness of the second insertion layer of AlN / AlInGaN is 100nm, the thickness of the second GaN layer 107 is 3000nm, AlGaN The thickness of the barrier layer is 50nm, Si 3 N 4 Passivation layer thickness 200nm, Ti / Al / Ni gate field plate, Ti / Al / Ni drain field plate, SiO 2 The thickness of the protective layer is 2000nm, and the p-type doping concentration of the AlInGaN gate insertion layer is: 1×10 21 cm -3 , the thickness is 50nm, the p-type GaN gate doping concentration is: 1×10 21 cm -3 , a thickness of 100nm, titanium / aluminum / nickel gate metal, titanium / al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com