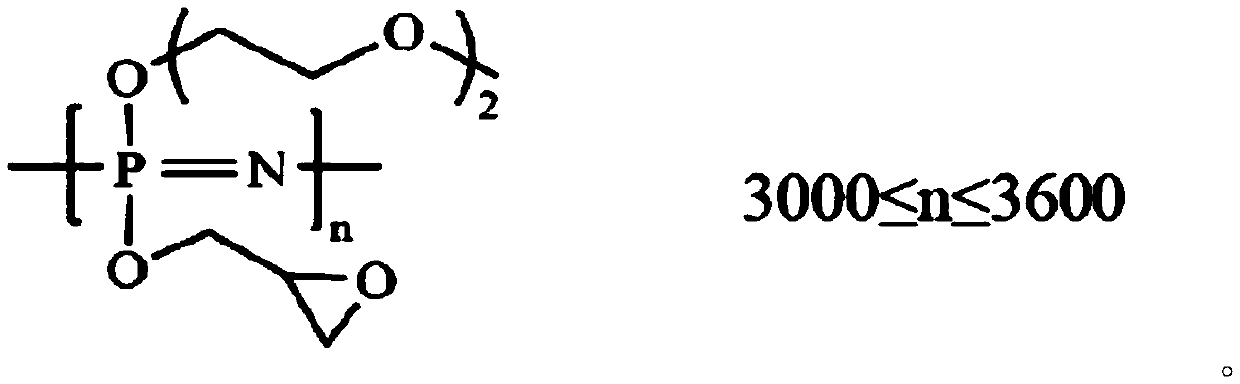

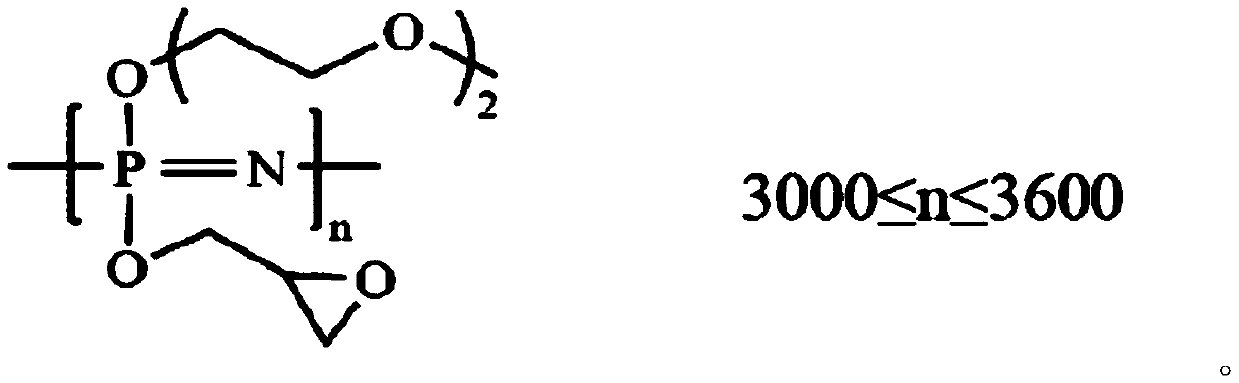

Preparation method of cyclic ether phosphazene polymer electrolyte membrane with excellent membrane forming performance

A technology of cyclic ether phosphazene and film-forming performance, which is applied in circuits, electrical components, secondary batteries, etc., can solve problems such as poor mechanical stability, achieve excellent film-forming performance, reduce the preparation process, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0027] Preparation of Epoxy Ether / Alkoxy Ether Substituted Polyphosphazene

[0028] Take 120g of tetrahydrofuran solution of polydiphosphazene, wherein the mass of polydichlorophosphazene is 10.08g, put it in a 1000mL three-necked flask, add a magnet to the there-necked flask, place the three-necked flask in an oil bath, and install a reflux condensation device; Weigh 6.45g of glycidyl alcohol and 8.81g of triethylamine, mix them evenly, drop them into a three-necked flask with a constant pressure dropping funnel, and react for 6h.

[0029] Another 250ml three-necked flask was placed in an ice-water bath, and 40ml of THF and 4.18gNaH after dehydration were added to the three-necked flask successively, protected by nitrogen gas, and magnetically stirred throughout the whole process, and 12.54g of diethylene glycol monomethyl ether was added dropwise with a dropping funnel into a three-neck flask. After the dropwise addition, the reaction was continued for 2h to obtain sodium d...

Embodiment example 2

[0033] Preparation of Epoxy Ether / Alkoxy Ether Substituted Polyphosphazene

[0034] Take 100 grams of tetrahydrofuran solution of polydiphosphazene, wherein the quality of polydichlorophosphazene is 8 grams, put it in a 1000mL three-necked bottle, add a magnet to the three-necked bottle, place the three-necked bottle in an oil bath, and install a condensation device; Weigh 5.12 grams of glycidyl alcohol and 6.98 grams of triethylamine, mix them evenly, add them into a three-necked flask with a constant pressure dropping funnel, and react for 6 hours.

[0035] Another 250ml three-necked flask was placed in an ice-water bath, and 40ml of dehydrated THF and 3.31gNaH were sequentially added into the three-necked flask, protected by nitrogen gas, and magnetically stirred throughout. 9.95 g of diethylene glycol monomethyl ether was dropped into a three-necked flask with a dropping funnel. After the dropwise addition, the reaction was continued for 2h to obtain sodium diethylene gly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com