Pt-GO-MW primary overflow body and preparation method and application of composite hydrogen storage material of Pt-GO-MW primary overflow body

A technology for hydrogen storage materials and fluids, applied in chemical instruments and methods, hydrogen, carbon compounds, etc., can solve problems such as disappearance, poor controllability of grinding methods, and decreased overflow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A method for preparing a Pt-GO-MW primary overflow with a microwave duration of 2 minutes, the specific steps are as follows:

[0070] Step 1, the hydrothermal reaction synthesis of Pt-GO, mixed 25 mg chloroplatinic acid with 100 mg graphene oxide, and then added 2 g vitamin C as a reducing agent to obtain a mixture, which was dissolved in water and ultrasonically mixed , under the condition of 120 ℃ to carry out hydrothermal reaction, you can get Pt-GO;

[0071] Step 2, microwave pore formation of Pt-GO, put the Pt-GO obtained in step 1 in a microwave oven, microwave pore formation under the conditions of microwave power of 700w and microwave time of 2 min, and then wash and freeze-dry The Pt-GO-MW primary overflow can be obtained, and the material obtained in Example 1 is named Pt-GO-MW2.

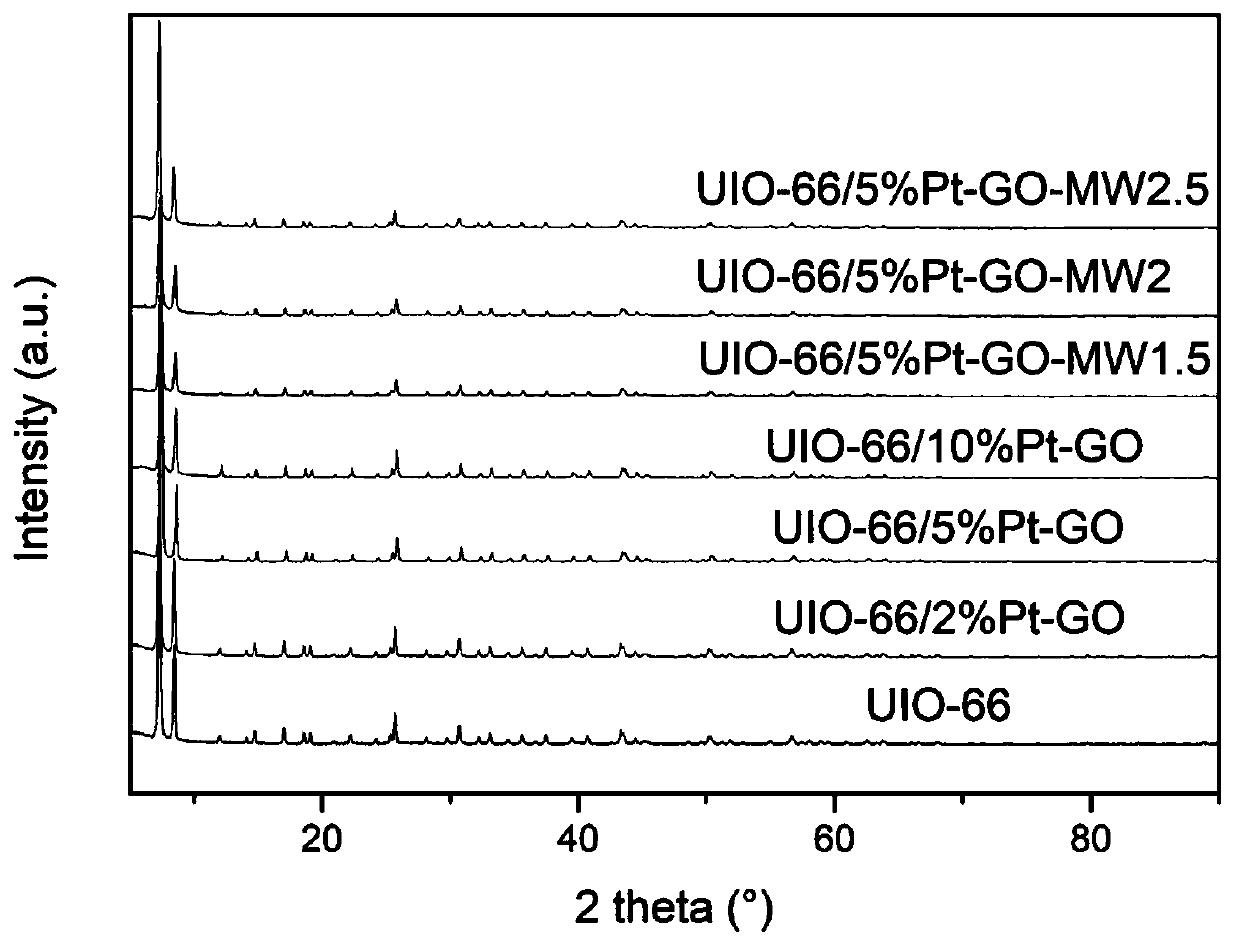

[0072] In order to prove the decisive effect of microwave treatment on pore formation and the effect of microwave pore formation in step 2, the Pt-GO obtained in step 1 and the Pt...

Embodiment 2

[0073] In order to prove the performance of the UIO-66 / Pt-GO-MW composite hydrogen storage material of the present invention, Example 2, the preparation method of the UIO-66 / Pt-GO-MW composite hydrogen storage material is provided.

[0074] Example 2

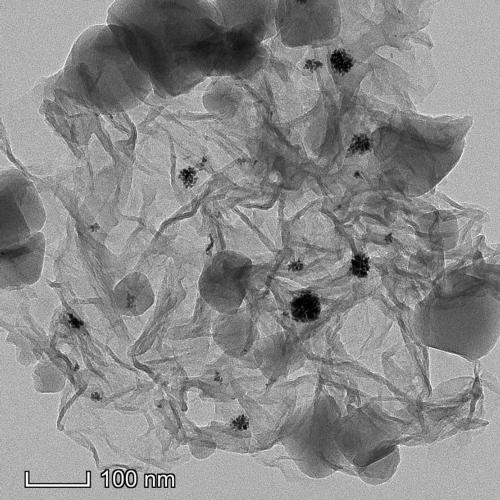

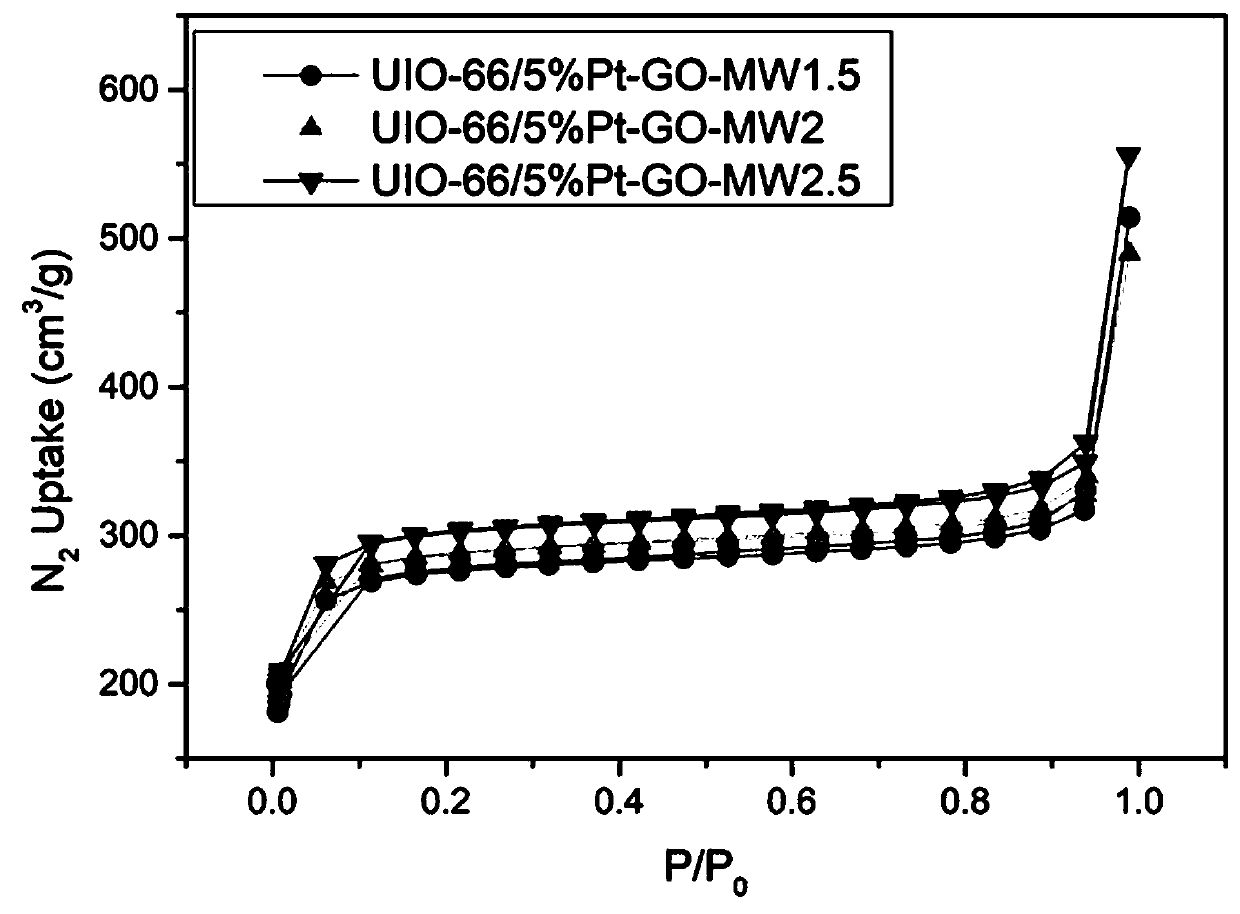

[0075]A preparation method of UIO-66 / Pt-GO-MW composite hydrogen storage material, the specific steps are as follows: the ratio of the amount of substances is 100:100:1, 0.233 mg zirconium tetrachloride, 0.166 mg terephthalic acid and 3.8 mL of formic acid were added in 20 mL of DMF, and then the addition of Pt-GO-MW primary overflow fluid was the ratio of 5% of UIO-66 quality, adding 0.01995 mg of Pt-GO-MW obtained in Example 1, After ultrasonic mixing, hydrothermal reaction was carried out at 120°C for 24 hours to obtain a gray powder material. After filtering and washing, the gray powder material obtained above was soaked in dichloro In methane for 3 days, and replace dichloromethane every 24h to replace high-boiling DMF, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com