High-energy-density lithium ion battery

A lithium-ion battery, high energy density technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as rupture, loss of electrochemical activity, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

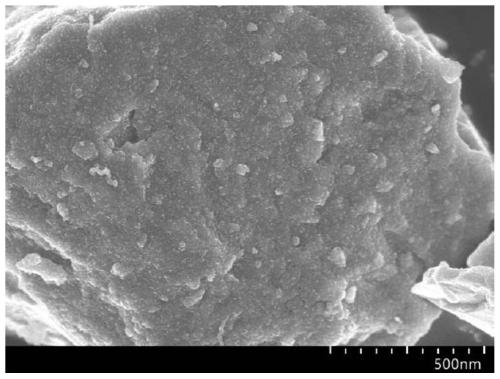

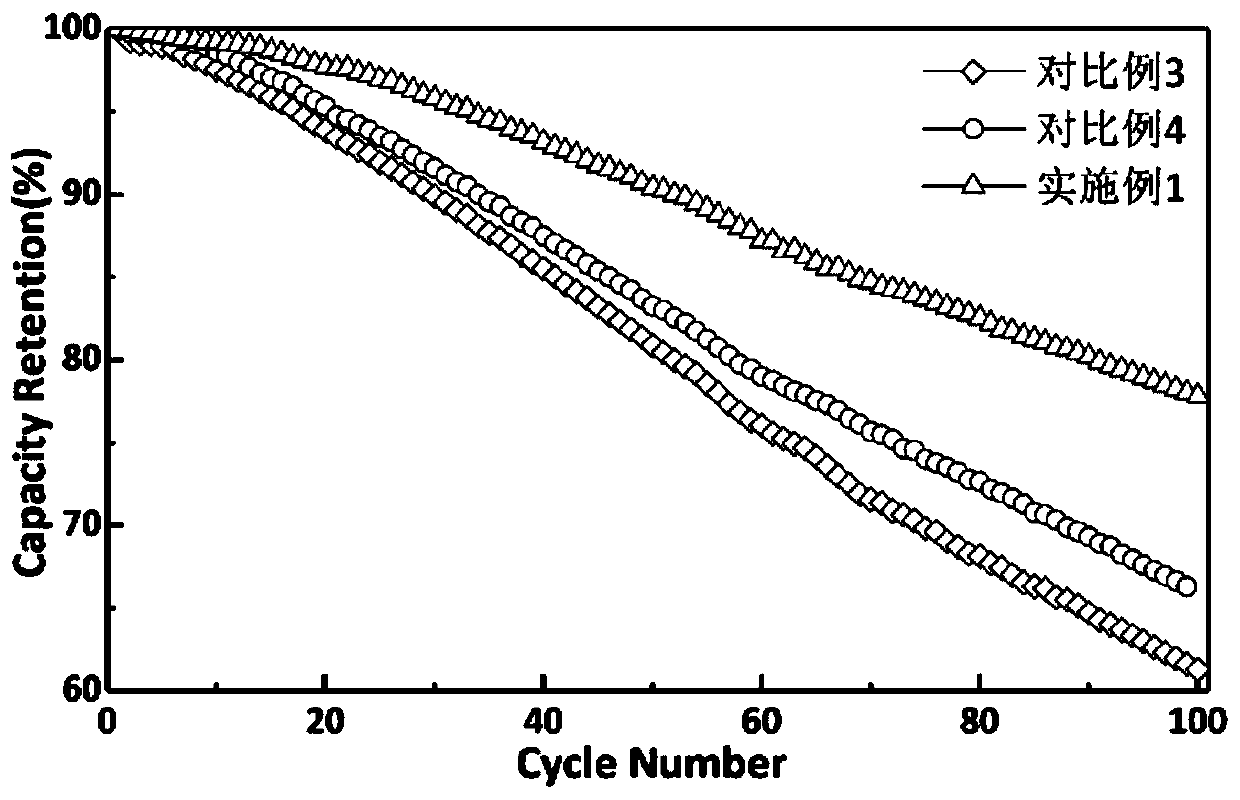

[0116] The negative electrode formula is replaced by: polysilicon particles (median particle size D50=0.8 micron, maximum particle size D100=2.5 micron) coated with carbon by chemical vapor deposition of the negative active material and conductive agent multi-armed carbon nanotubes, conductive graphite, The mass ratio of thickener carboxymethylcellulose sodium (CMCNa), sodium polyacrylate (PAANa), binder styrene-butadiene rubber (SBR), and polystyrene acrylic acid copolymer is 80:2:3:3:4: 5:3; electrode porosity is 35%. Among them, the powder obtained by crushing polysilicon is coated with carbon on the surface by chemical vapor deposition: the polysilicon powder is placed in the center of the tube furnace, and acetylene is introduced as the precursor of the carbon coating layer, and the surface coating is obtained by heating at 940°C for 2.5 hours. Carbon-coated polysilicon powder. The amount of carbon coated on the surface of silicon particles is 4.5%.

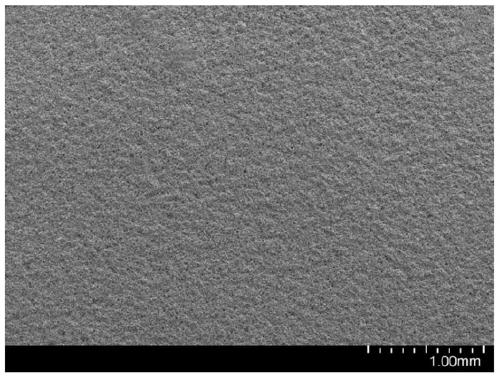

[0117] figure 1...

Embodiment 2

[0121] The negative electrode formula is replaced by: polysilicon particles (median particle size D50=0.8 micron, maximum particle size D100=2.5 micron) coated with carbon by chemical vapor deposition of the negative active material and conductive agent multi-armed carbon nanotubes, conductive graphite, The mass ratio of thickener carboxymethylcellulose sodium (CMCNa), sodium polyacrylate (PAANa), binder styrene-butadiene rubber (SBR), and polystyrene acrylic acid copolymer is 80:2:3:3:4: 5:3; electrode porosity is 35%. Among them, the powder obtained by crushing polysilicon is coated with carbon on the surface by chemical vapor deposition: the polysilicon powder is placed in the center of the tube furnace, and acetylene is introduced as the precursor of the carbon coating layer, and the surface coating is obtained by heating at 940°C for 2.5 hours. Carbon-coated polysilicon powder. The amount of carbon coated on the surface of silicon particles is 4.5%.

[0122] After tes...

Embodiment 3

[0124] The negative electrode formula is replaced by: polysilicon particles (median particle size D50=0.8 micron, maximum particle size D100=2.5 micron) coated with carbon by chemical vapor deposition of the negative active material and conductive agent multi-armed carbon nanotubes, conductive graphite, The mass ratio of thickener carboxymethylcellulose sodium (CMCNa), sodium polyacrylate (PAANa), binder styrene-butadiene rubber (SBR), and polystyrene acrylic acid copolymer is 80:2:3:3:4: 5:3; electrode porosity is 35%. Among them, the powder obtained by crushing polysilicon is coated with carbon on the surface by chemical vapor deposition: the polysilicon powder is placed in the center of the tube furnace, and acetylene is introduced as the precursor of the carbon coating layer, and the surface coating is obtained by heating at 940°C for 2.5 hours. Carbon-coated polysilicon powder. The amount of carbon coated on the surface of silicon particles is 4.5%.

[0125] After tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com