Composite binder for negative electrode of silicon-based lithium-ion battery and preparation method thereof, and silicon-based lithium-ion battery

A lithium-ion battery, ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of inability to effectively disperse negative electrode particles and high interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

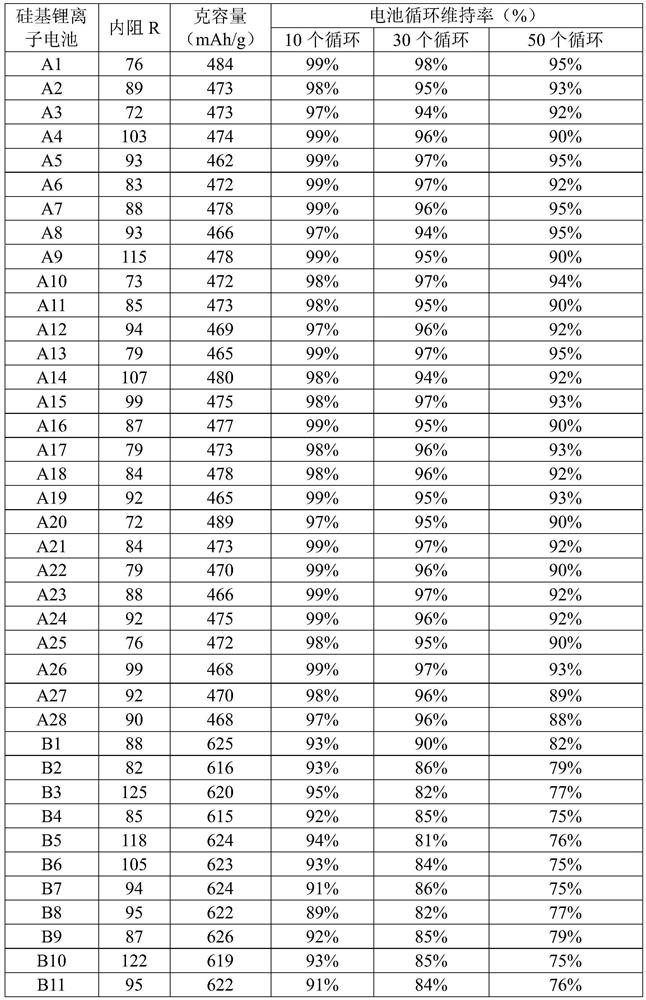

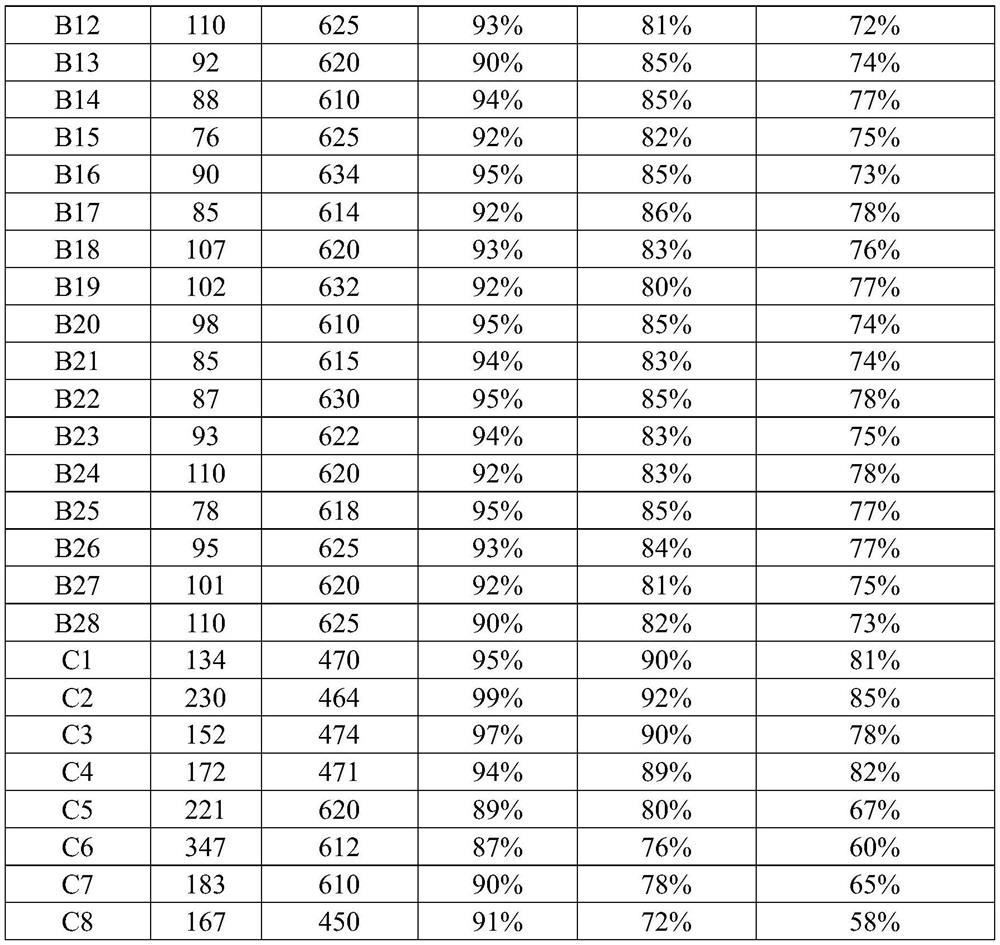

Examples

preparation example Construction

[0026] The method of preparing a composite binder with a silicon-based lithium ion battery negative electrode provided by the present invention includes the following steps:

[0027] Aqueous solution of aqueous polymer binder is provided; the first unsaturated ethylene monomer, the second unsaturated olefinoid monomer, and the initiator are added to the aqueous solution; the first The unsaturated olefinoid is selected from the group consisting of organic acids of the first carbon-containing carbon double bond, the organic acid salt of the first carbon-containing carbon double bond, the first carbon-containing carbon double-bonded amide, the first carbon-containing carbon double bond At least one of the second unsaturated ethylenically monomers selected from the second carbon-containing carbon double-containing amide, the second carbon-containing carbon double bond ester, the second carbon-containing carbon double bond organic acid, At least one of the organic acid salts containing...

Embodiment 1

[0048] The method for preparing a composite binder of the silicon-based lithium ion battery negative electrode, including the following steps:

[0049] 1) Add 10 g of carboxymethylcellulose and 300 g of deionized water to 500 ml of three bottles, stirred with 200 rwand / division to stir up to 80 ° C, heat insulation 2h is completely dissolved, to obtain a sodium carboxymethylcellulose sodium dispersion; The average molecular weight of the carboxymethylcellulose used is 300,000;

[0050] 2) Reduce the resulting carboxymethylcellulose sodium dispersion to 70 ° C, 8.1 g of water-soluble unsaturated ethylene monomer acrylic acid, and hydroxyethyl acrylate 13.2 g dispersion uniform (calculated sodium carboxymethylcarbonate) The molar ratio of the structural unit, acrylic acid, and hydroxyethyl acrylate is 1: 2.5: 2.5), passed into high purity nitrogen emptying oxygen for 1 h, then gradually added 30 g of aqueous solution of 0.21 g of ammonium persulfate, and then adding 4H.

[0051] A...

Embodiment 2

[0055] The method of preparing a composite binding agent for the negative electrode of the silicon-based lithium ion battery of the present embodiment, including the steps of:

[0056] 1) Add 30 g of sodium alginate and 300 g of deionized water to 500 ml of three bottles, stirred with 200 rwat / min, and heat up to 80 ° C, heat insulation 2h is completely dissolved, to obtain sodium alginate dispersion; sodium alginate The average molecular weight is 50,000;

[0057] 2) Reduce the resulting alginate dispersion to reduce temperature to 70 ° C, add water-soluble monomer unsaturated ethylenically acrylic acid 5.5 g and hydroxyethyl acrylate 8.96g dispersion (calculated structural unit, acrylic acid, acrylic acid) The molar ratio of hydroxyethyl acrylate is 2: 1: 1), which is introduced into high purity nitrogen emptying oxygen for 1 h, and then adding 30 g of aqueous solution containing 0.21 g of ammonium persulfate, 4H drop;

[0058] As the initiator is added, the polymerization rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com