Efficient sterilizing foam decontaminant and preparation method thereof

The technology of a detergent and a foam agent is applied in the field of high-efficiency sterilization foam detergent and its preparation, so as to achieve the effects of speeding up the reaction rate, improving the efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

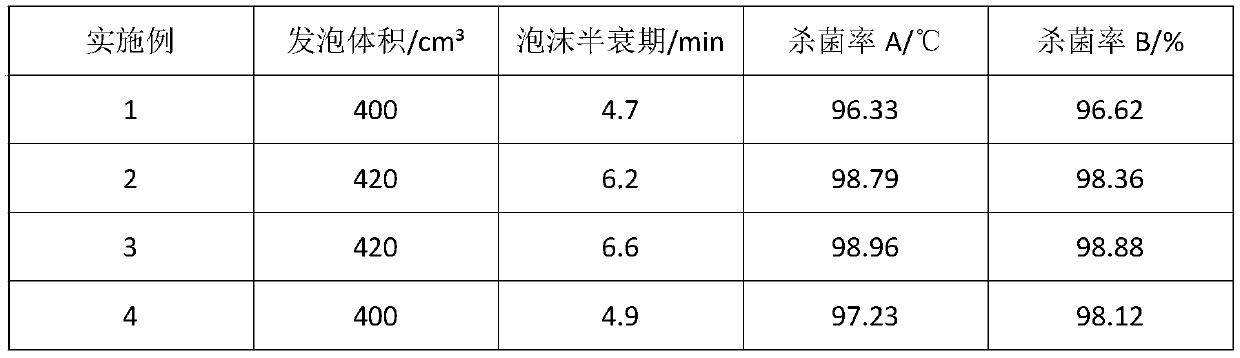

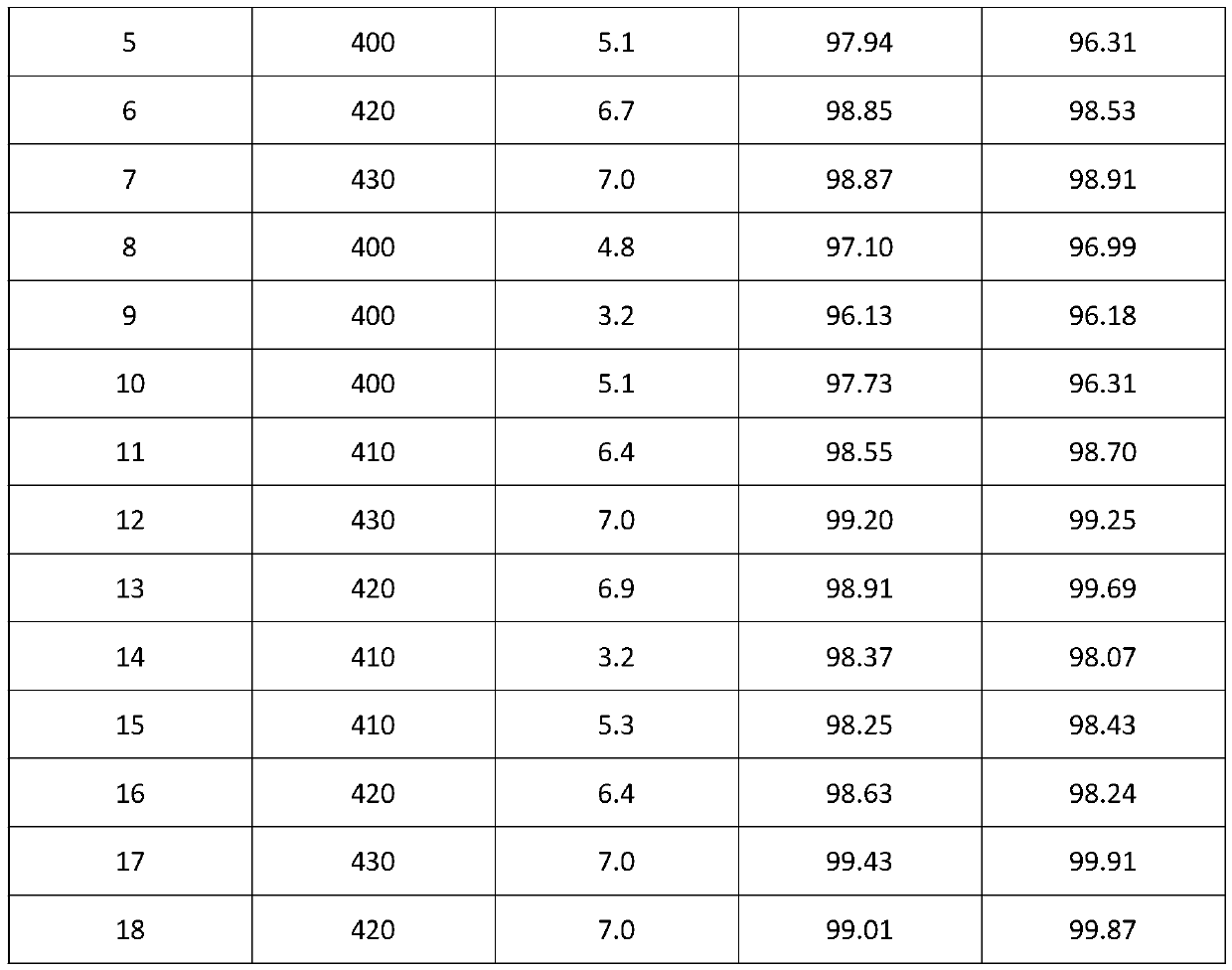

Examples

experiment example

[0058] plan 1

[0059] Preparation of a high-efficiency bactericidal foam detergent:

[0060] 1. Add 1000 g of deionized water to the reaction vessel.

[0061] 2. Add 485g of propylene carbonate to the container, which is 25% by mass, and control the temperature in the container to 25°C, and use ultrasonic vibration to stir evenly.

[0062] 3. Mix and stir 0.1g aluminum trichloride, 0.1g sodium hydroxide and 10g deionized water, and use a 20-mesh sieve to sieve three times to prepare an adjuvant.

[0063] 4. Add the prepared auxiliary agent to the container, and control the temperature in the container to 25°C, and use ultrasonic vibration to stir evenly.

[0064] 5. Add 426.8g of hydrogen peroxide to the container, which is 22% by mass, and control the temperature in the container to 25°C, and use ultrasonic vibration to stir evenly.

[0065] 6. Add 15.5 g of sodium bicarbonate to the container, which is 0.8% by mass, and control the temperature in the container to 25° C., use ultrasonic...

Embodiment 1

[0092] Preparation of a high-efficiency bactericidal foam detergent:

[0093] 1. Add 1000 g of deionized water to the reaction vessel.

[0094] 2. Add 485g of propylene carbonate to the container, which is 25% by mass, and control the temperature in the container to 25°C, and use ultrasonic vibration to stir evenly.

[0095] 3. Add 426.8g of hydrogen peroxide to the container, which is 22% by mass, and control the temperature in the container to 25°C, and use ultrasonic vibration to stir evenly.

[0096] 4. Add 15.5g of sodium bicarbonate to the container, that is, 0.8% by mass, and control the temperature in the container to 25°C, and use ultrasonic vibration to stir evenly.

[0097] 5. Add 1.9g of sodium lauryl sulfate to the container, which is 0.1% by mass, and control the temperature in the container to 25°C, and use ultrasonic vibration to stir evenly.

[0098] 6. Add 5.8 g of sodium dodecylbenzene sulfonate, which is 0.3% by mass, to the container, and control the temperature in t...

Embodiment 2

[0101] Preparation of a high-efficiency bactericidal foam detergent: The preparation process of this embodiment is substantially the same as that of Embodiment 1, except that the sodium dodecylbenzene sulfonate used in this embodiment accounts for 0.4% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com