Supported noble metal catalyst based on carrier morphology modification and its preparation and application

A noble metal catalyst, supported technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve low catalytic activity, long-term working stability and moisture resistance To achieve the effect of high-efficiency catalytic formaldehyde decomposition, excellent stability and moisture resistance, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Catalyst preparation:

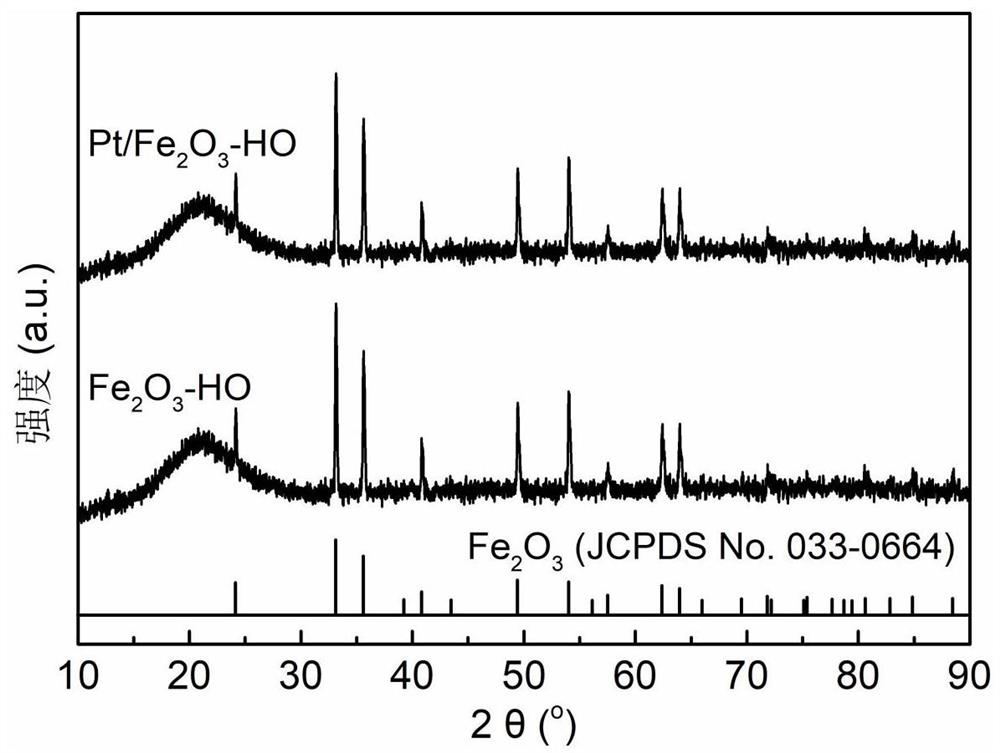

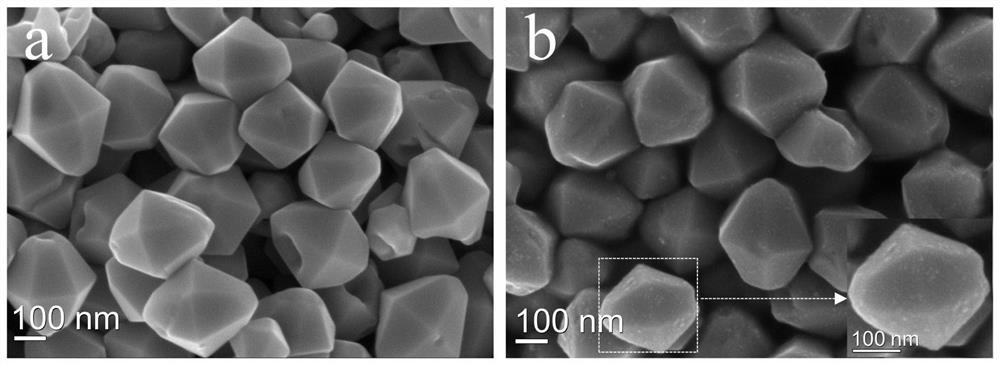

[0041] Fe 2 o 3 Synthesis of -HO: 1.0mmol FeCl 3 ·6H 2 O and 10.5mmol NaF were dissolved in 30mL ultrapure water to form a transparent solution, and 0.12mL NH 3 ·H 2 O (12%) was added to the above solution to continue sonication for 10 minutes. Subsequently, the above-mentioned suspension was placed in a hydrothermal kettle with a volume of 50 mL, and after being treated at a constant temperature of 180 °C for 24 hours, it was naturally cooled to room temperature. Carry out vacuum drying 6 hours; Make target carrier Fe 2 o 3 -HO.

[0042] Pt / Fe 2 o 3 Synthesis of -HO: 100 mg of Fe synthesized above 2 o 3 -HO was dispersed in 10 mL of ultrapure water, and 0.27 mL of H 2 PtCl 6 (19.3mM) solution was continuously stirred for 30 minutes; subsequently, 1.70mL of NaBH 4 (0.1M) and NaOH (0.1M) mixed reducing agent was added to the suspension and stirred for 2 hours. The prepared sample was fully cleaned and then vacuum-dried at 60°C ...

Embodiment 2

[0053] (1) Catalyst preparation:

[0054] In the synthesis method of the present embodiment, only FeCl 3 ·6H 2 O is replaced by Fe(NO 3 ) 3 9H 2 O and H 2 PtCl 6 Replaced with HAuCl 4 , all the other preparation conditions are consistent with Example 1.

[0055] (2) Phase / structural characterization of the catalyst:

[0056] The obtained hydrothermal state sample Fe of the present embodiment 2 o 3 -HO and Au loaded sample Au / Fe 2 o 3 X-ray diffraction of -HO as Figure 9 shown. According to XRD analysis ( Figure 9 ), the synthesized hydrothermal samples and Au-loaded samples are both α-Fe 2 o 3 crystal phase.

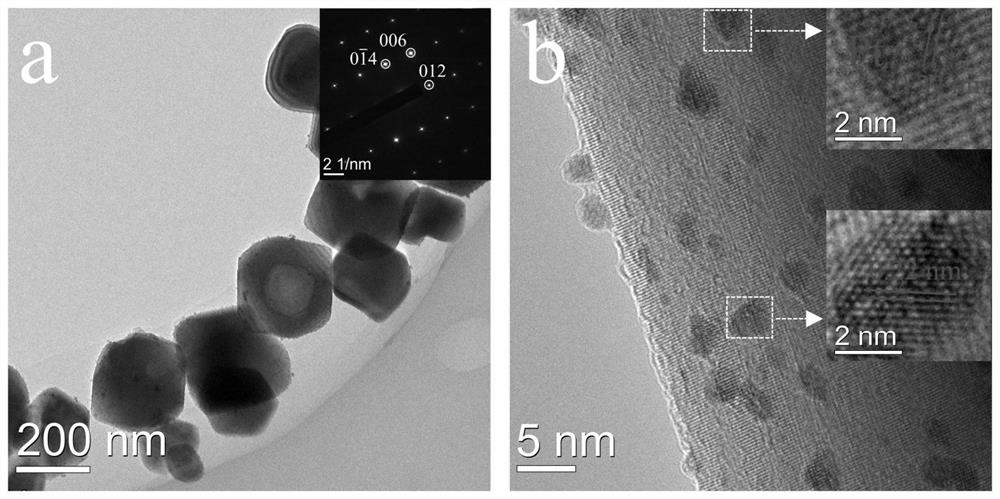

[0057] Transmission electron microscope observation ( Figure 10 In a) it is found that the structure of the target catalyst is consistent with that of Example 1, which is octadecahedral Fe with a hollow structure 2 o 3 Supported Au catalyst (Au / Fe 2 o 3 -HO), at the same time, it was found that there were a large number of newly generated nanopar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com