Vertical channel tunable high-flux acoustic fluidic sorting chip and preparation method thereof

A vertical channel, high-throughput technology, applied in the field of micro-total analysis, can solve the problems of complex preparation, increase preparation cost, low sorting throughput, etc., and achieve the effect of saving samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

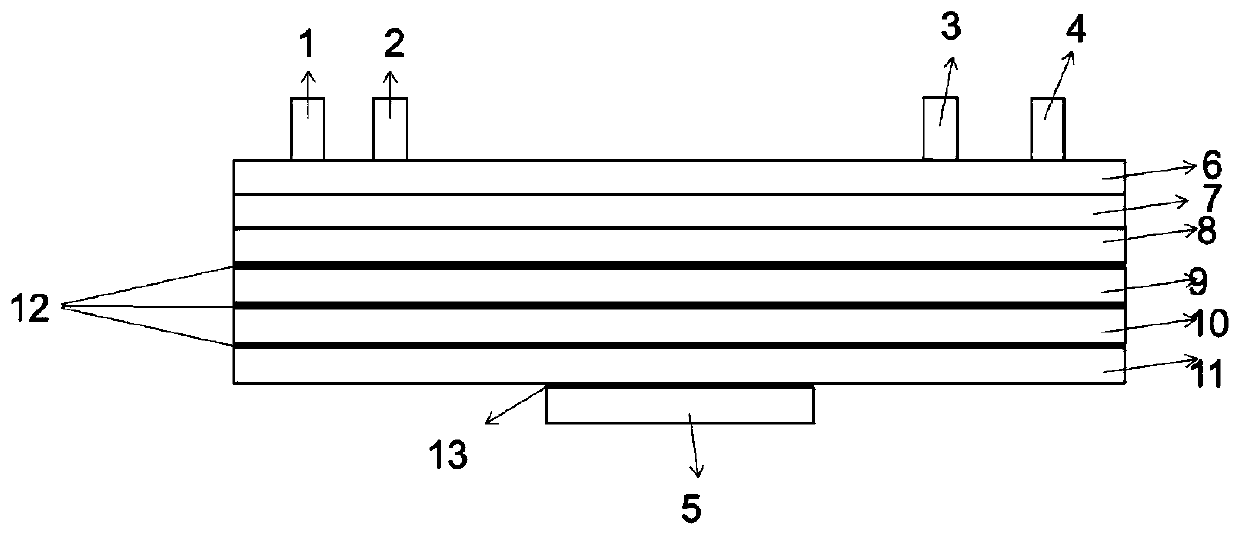

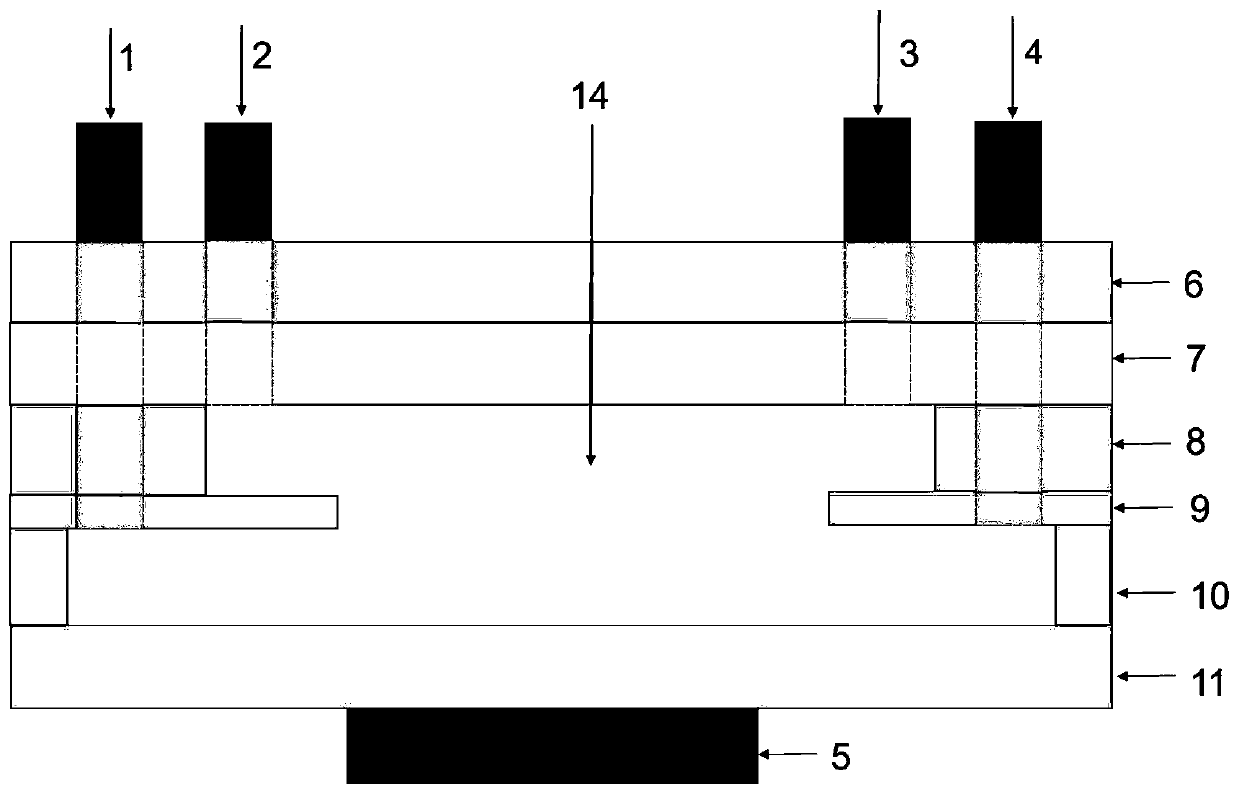

[0062] Preparation of high-throughput acoustofluidic sorting chips

[0063] The preparation method is as follows:

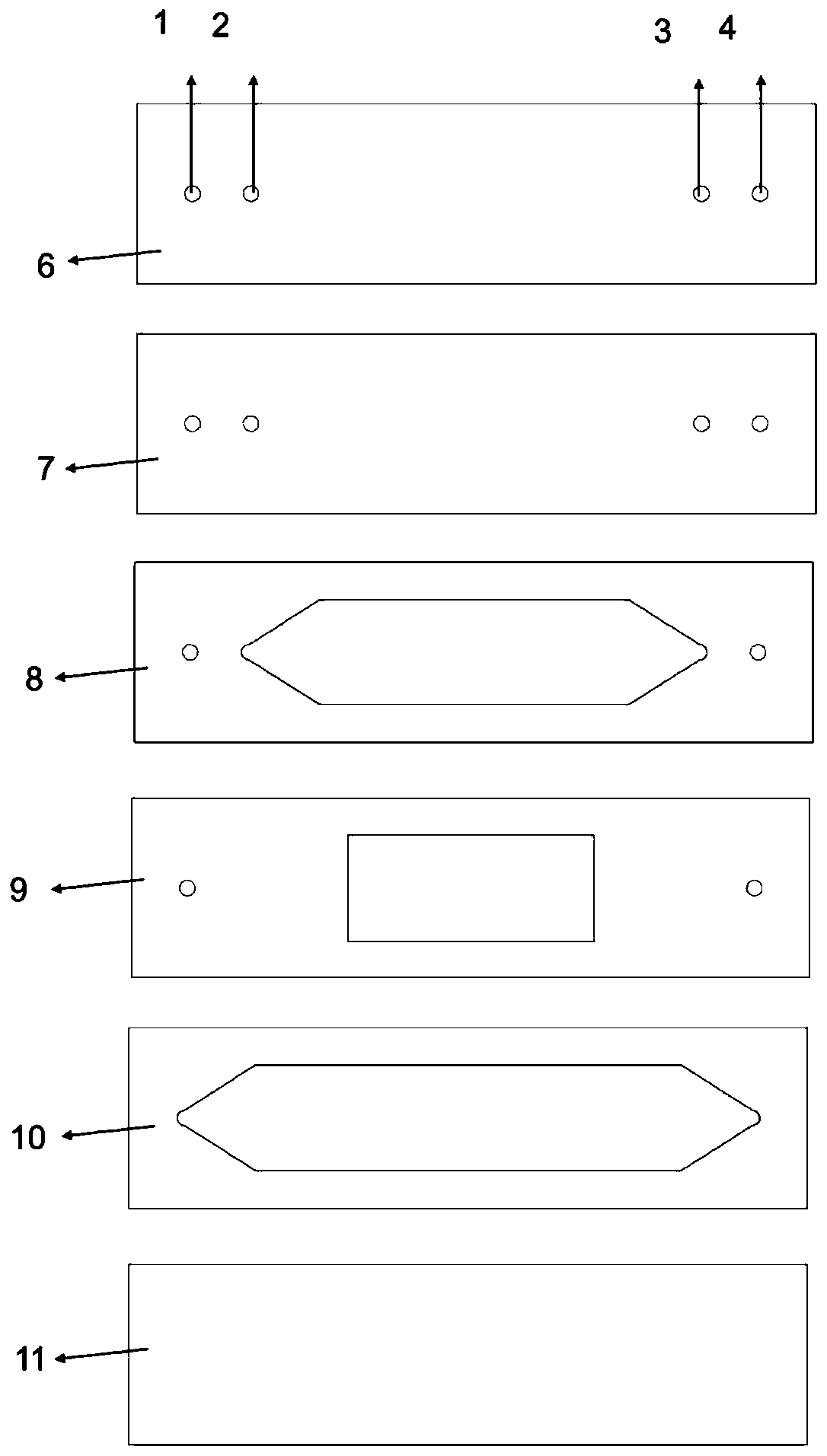

[0064] (1) 5 pieces of glass sheets and PDMS film 7 are prepared, wherein the glass sheet includes a back sheet 11, a spacer I10, a spacer I9, a spacer II 8, and a top sheet 6;

[0065] (2) Cut glass sheets with different thicknesses by laser, and process 5 glass sheets with the same overall size with hollow shape;

[0066] The negative 11, the thickness is 1.25mm;

[0067] Gasket I 10, the middle hollow is hexagonal, the thickness is 200μm;

[0068] The spacer I 9 has a square hollow in the middle and a thickness of 75 μm;

[0069] The hollow in the middle of the gasket II 8 is hexagonal, which is exactly the same as the gasket I10 as a whole, with a thickness of 200 μm;

[0070] PDMS film 7, thickness 200μm;

[0071] Top sheet 7, the thickness is 1.25mm;

[0072] Among them, the size of the hollow area: gasket I > gasket II > spacer I;

[0073] The two e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com