Preparation process of diamond tool

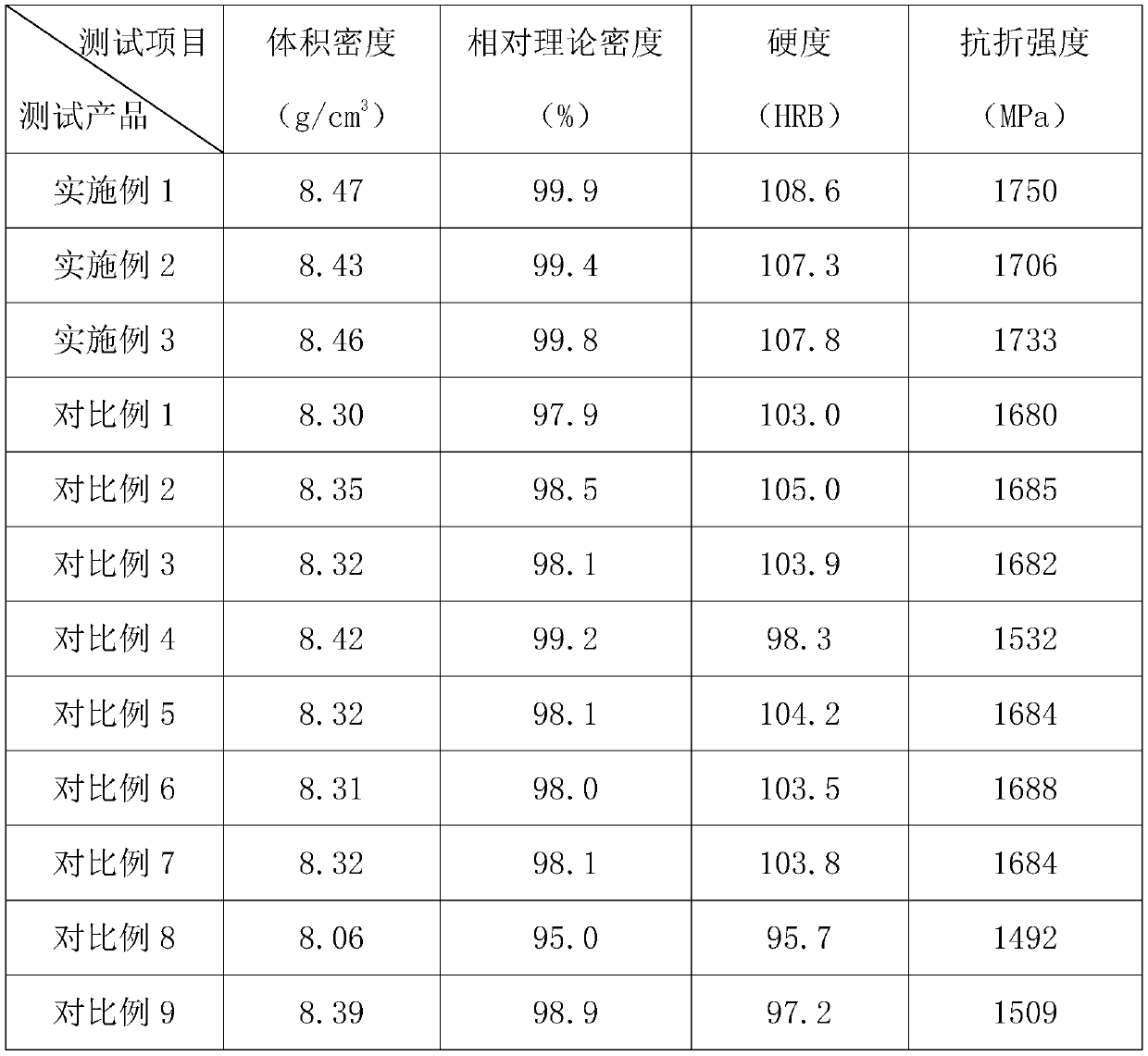

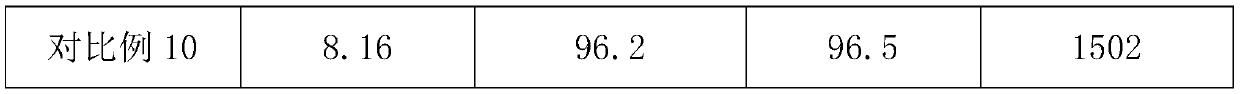

A diamond tool and a preparation technology, which is applied in the field of diamond tool preparation, can solve problems such as easy shedding of diamond particles, stoppage of diamond tool production, and shortened service life, and achieve high sintering reactivity, improved holding force, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation process of a diamond tool, comprising the following steps:

[0034] Step A, mixing the ethanol-soluble water-soluble polymer binder with the ethanol-soluble non-water-soluble polymer binder to prepare a binder composition that is completely soluble in ethanol and partially soluble in water ;

[0035] Step B, dissolving the binder composition prepared in step A with ethanol to prepare a binder solution;

[0036] Step C, dry mixing the metal pre-alloyed powder and diamond particles to obtain a matrix alloy dry mix;

[0037] Step D, heating and kneading the binder solution prepared in step B and the carcass alloy dry mixture prepared in step C, and then granulating to obtain carcass alloy pellets;

[0038] Step E, pressing and molding the carcass alloy pellets prepared in step D to obtain a carcass alloy blank;

[0039] Step F, soaking and degreasing the carcass alloy blank prepared in step E, and then performing drying and pre-oxidation treatment;

[004...

Embodiment 1

[0079] A kind of diamond tool is prepared according to the following steps:

[0080] Step A, calculated according to the mass percentage, weighed 65% polyethylene glycol (polymerization degree of 2000) and mixed with 35% polyvinyl butyral to prepare a binder combination that is completely soluble in ethanol and partially soluble in water thing;

[0081] Step B, prepare binder solution

[0082] Step B1, according to the mass percentage calculation, weigh 30% of the binder composition prepared in step A and 70% ethanol, put the weighed ethanol into a sealed beaker and heat it to 50°C and keep the temperature constant, turn on the stirrer for ethanol to stir;

[0083] Step B2, adding the weighed binder composition into ethanol, stirring and dissolving, and preparing a binder solution;

[0084] Step C, calculated by volume percentage, weighed 92.5% metal pre-alloyed powder (calculated by mass percentage, the metal pre-alloyed powder was obtained by mixing the following metal powd...

Embodiment 2

[0096] A kind of diamond tool is prepared according to the following steps:

[0097] Step A, calculated according to the mass percentage, weighed 60% polyethylene glycol (polymerization degree of 1500) and mixed with 40% polyvinyl butyral to prepare a binder combination that is completely soluble in ethanol and partially soluble in water thing;

[0098] Step B, prepare binder solution

[0099] Step B1, according to the mass percentage calculation, weigh 30% of the binder composition prepared in step A and 70% ethanol, put the weighed ethanol into a sealed beaker and heat it to 50°C and keep the temperature constant, turn on the stirrer for ethanol to stir;

[0100] Step B2, adding the weighed binder composition into ethanol, stirring and dissolving, and preparing a binder solution;

[0101] Step C, calculated by volume percentage, weighed 92.5% metal pre-alloyed powder (calculated by mass percentage, the metal pre-alloyed powder was obtained by mixing the following metal po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com