A kind of preparation method of concentrated graphene oxide solution and thermal conductive film

A graphene solution, graphene technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as unfavorable scaled production, low thermal conductivity, weak heat conduction and heat dissipation, and shorten the drying time. , The preparation method is simple, and the effect of improving the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

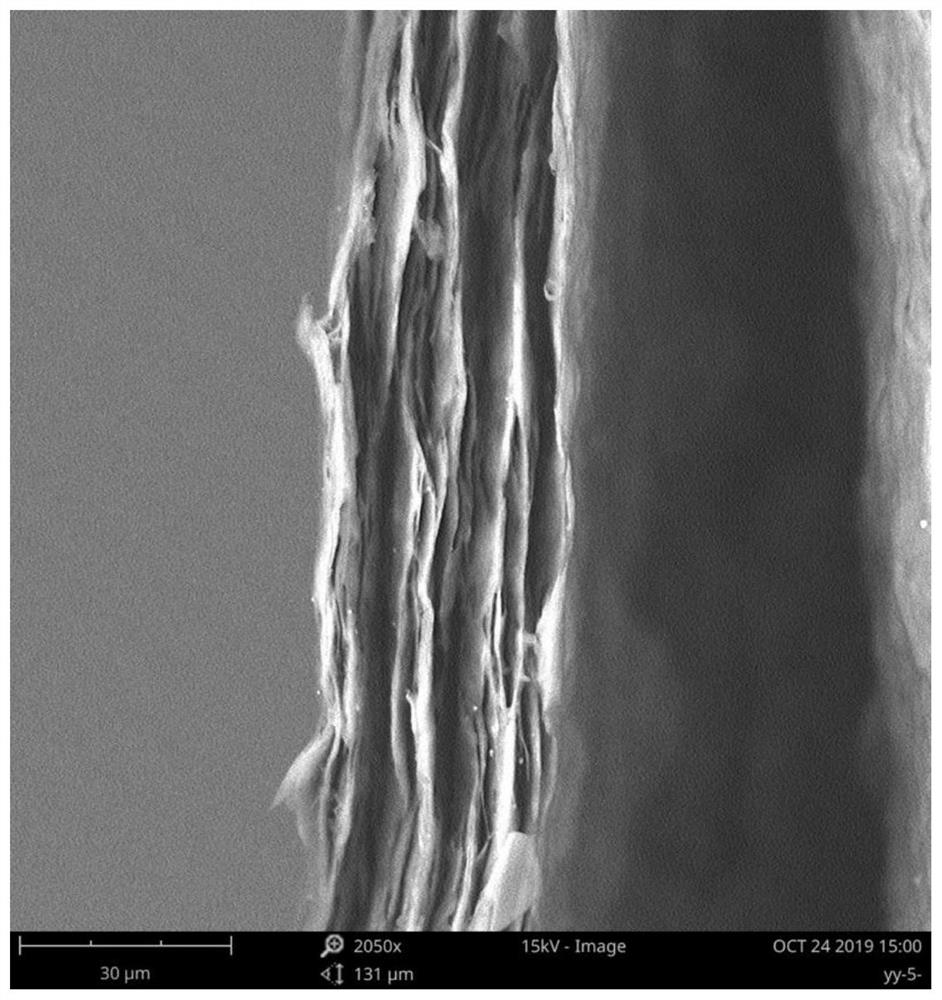

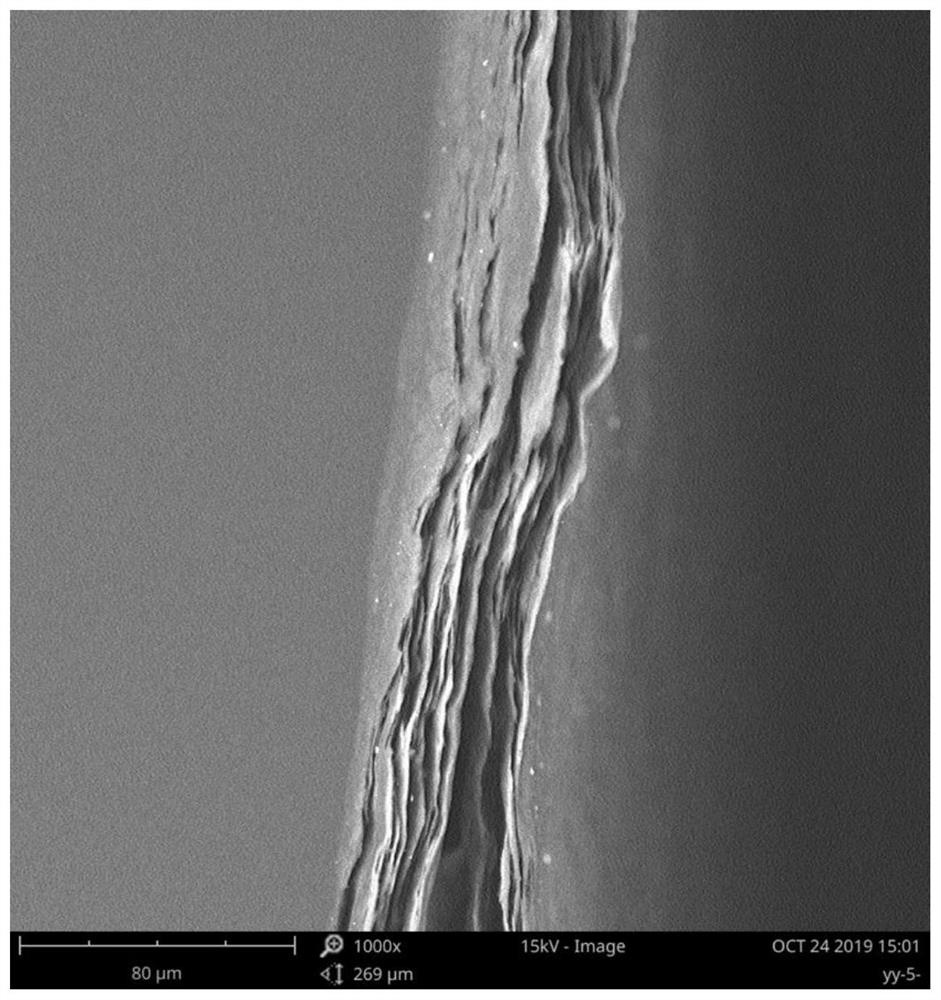

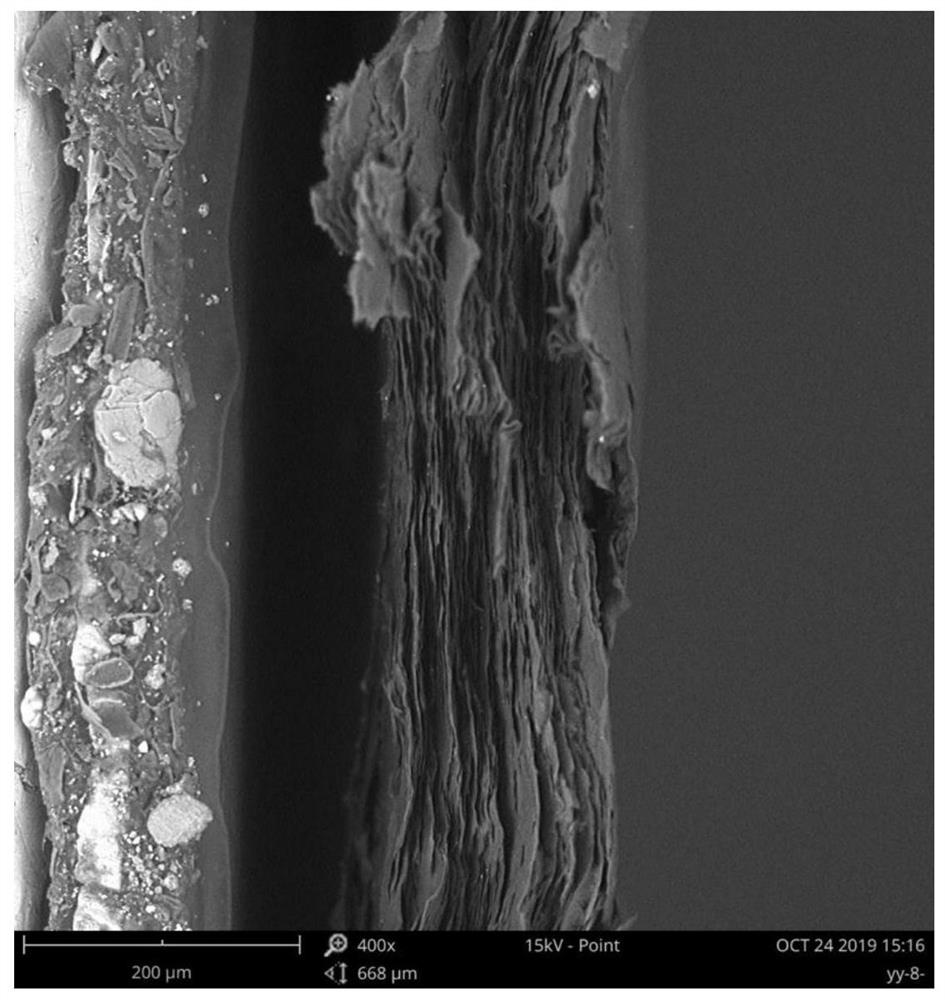

[0028] Embodiments of the present invention provide a method for preparing a concentrated graphene oxide solution in a first aspect. The preparation method includes the following steps: S101, forming a negative charge on the surface of graphene oxide in the graphene oxide aqueous solution; S102, using a metal salt to have The negatively charged graphene oxide aqueous solution is colloidized to form a metal-doped graphene oxide colloid; S103, the metal-doped graphene oxide colloid is concentrated and separated to obtain a metal-doped graphene oxide aqueous solution, that is, concentrated graphene oxide solution.

[0029] The embodiment of the present invention does not limit the specific implementation methods of the three processes of negative charge formation, colloidization, and concentration and separation, as long as a concentrated graphene oxide solution can be obtained.

[0030] In the embodiment of the present invention, negative charges are first formed on the surface ...

Embodiment 1

[0050] The preparation method of the concentrated graphene oxide solution is as follows: adopting a power of 350W and an ultraviolet lamp with an ultraviolet wavelength of 280-380nm to irradiate the graphene oxide aqueous solution with a mass concentration of 1% for 5 minutes, so that a large amount of negative charges are generated on the surface of the graphene oxide, A graphene oxide aqueous solution with a negative charge is obtained. Add ferric nitrate in the graphene oxide aqueous solution with negative charge, stir 10min with the speed of 600r / min, make the iron ion in the system and graphene oxide surface negative charge fully combine, generate the graphene oxide colloid of iron doping; Wherein , the mass ratio of ferric nitrate to graphene oxide is 1:10000. The iron-doped graphene oxide colloid was crystallized at a low temperature of -10°C for 12 hours, and the ice crystals were eliminated after natural heating at room temperature to generate a mixed solution; the mi...

Embodiment 2

[0054] The preparation method of the concentrated graphene oxide solution is as follows: adopting a power of 350W and an ultraviolet lamp with an ultraviolet wavelength of 280-380nm to irradiate the graphene oxide aqueous solution with a mass concentration of 1% for 15 minutes, so that a large amount of negative charges are generated on the surface of the graphene oxide, A graphene oxide aqueous solution with a negative charge is obtained. Add copper nitrate to the graphene oxide aqueous solution with negative charge, stir 30min with the speed of 600r / min, make the copper ion in the system and graphene oxide surface negative charge fully combine, generate the graphene oxide colloid of copper doping; Wherein , the mass ratio of copper nitrate to graphene oxide is 3:10000. The copper-doped graphene oxide colloid was crystallized at a low temperature of -12°C for 15 hours, and the ice crystals were eliminated after natural heating at room temperature to form a mixed solution; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com