Ferrierite with high silica-alumina ratio and preparation method and application thereof

A high-silicon-aluminum-ratio ferrierite and ferrierite technology, which is applied in chemical instruments and methods, isomerization hydrocarbon production, unsaturated hydrocarbon addition hydrocarbon production, etc., can solve the problem of improving requirements and increasing synthesis steps System complexity and other issues, to achieve the effect of ensuring utilization rate, simple and easy preparation method, and simplified preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of silicon source mother liquor

[0050] 0.566g of sodium hydroxide and 0.429g of potassium hydroxide were dissolved in 115g of deionized water, then 67.947g of silica sol with a silica content of 30wt% was added dropwise, and the obtained mixture was stirred in a water bath at 70°C for 80min. The molar ratio of the mixture: Na 2 O / SiO 2 =0.0338, K 2 O / SiO 2 =0.0162,H 2 O / SiO 2 = 15.9.

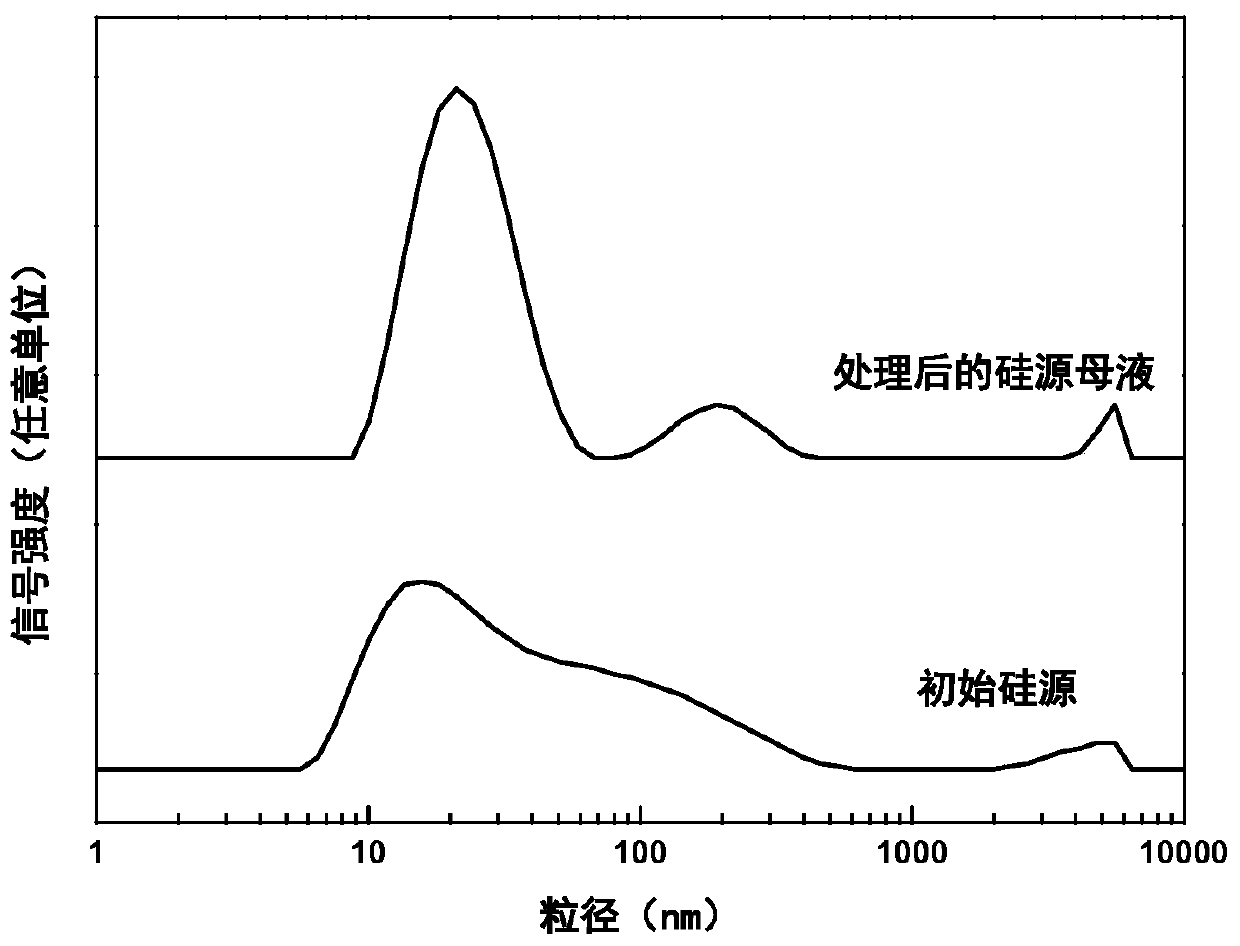

[0051] figure 2 It is the particle size distribution diagram before and after the treatment of the silicon source in Example 1. The particle size distribution of the alkali-treated silica sol at 70°C changes significantly. The average particle size of the initial silicon source in this embodiment is 27.11nm as measured by the laser particle size analyzer. The average particle size of the treated silicon source mother liquor is 25.7nm.

Embodiment 2

[0053] Preparation of silicon source mother liquor

[0054] 1.817g of sodium hydroxide and 1.232g of potassium hydroxide were dissolved in 195g of deionized water, then 124.625g of silica sol with a silica content of 30wt% was added dropwise, and the obtained mixture was stirred in a water bath at 40°C for 30min. The molar ratio of the mixture: Na 2 O / SiO 2 =0.035,K 2 O / SiO 2 =0.015,H 2 O / SiO 2 = 17.4.

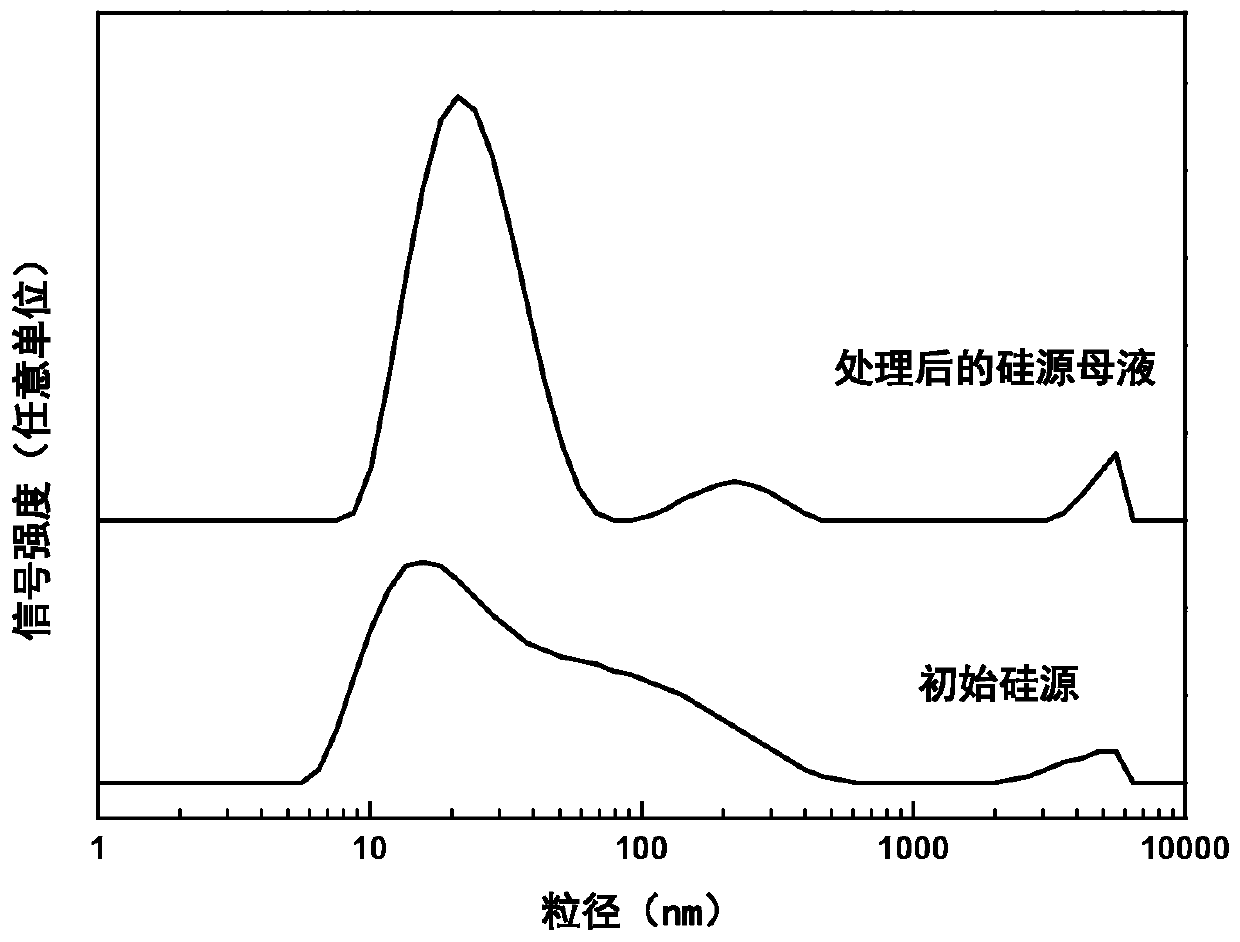

[0055] image 3 It is the particle size distribution diagram before and after the treatment of the silicon source in Example 2. The average particle size of the initial silicon source in this embodiment measured by the laser particle size analyzer is 27.11nm, and the average particle size of the treated silicon source mother liquor is 25.03nm.

Embodiment 3

[0057] Preparation of silicon source mother liquor

[0058] 1.817g of sodium hydroxide and 1.232g of potassium hydroxide were dissolved in 195g of deionized water, then 124.625g of silica sol with a silica content of 30wt% was added dropwise, and the obtained mixture was stirred in a water bath at 70°C for 80min. The molar ratio of the mixture: Na 2 O / SiO 2 =0.035,K 2 O / SiO2=0.015, H 2 O / SiO 2 = 17.4.

[0059] Figure 4 It is the particle size distribution diagram before and after the treatment of the silicon source in Example 3. The average particle size of the initial silicon source in this embodiment measured by the laser particle size analyzer is 49.24nm, and the average particle size of the treated silicon source mother liquor is 44.07nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com