Low-cost and high-efficiency high-strength waterproof concrete and preparation method thereof

A waterproof concrete, high-strength technology, applied in the field of concrete, can solve the problems of hindering the actual reaction of waterproofing agent, increasing the amount of waterproofing agent used, reducing the efficiency of waterproofing agent, etc., to achieve the effect of improving waterproofing efficiency, reducing dosage, and improving drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

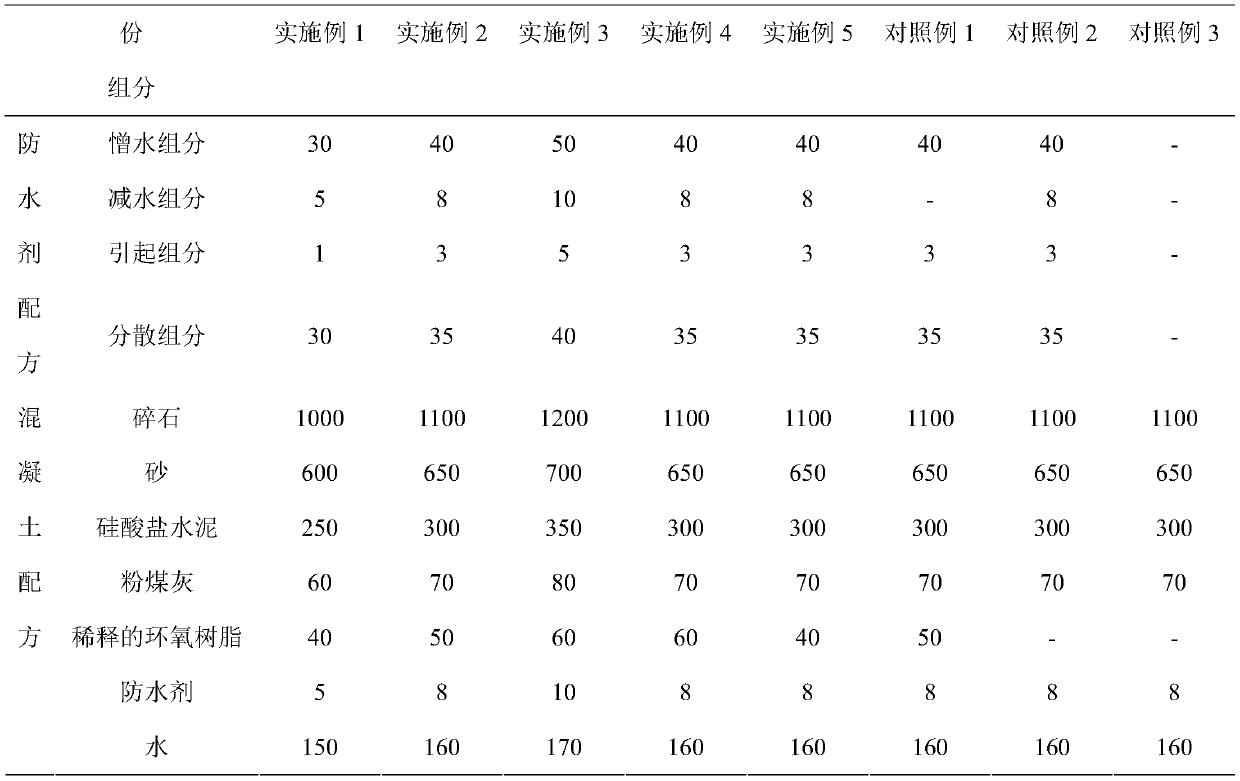

[0029] The waterproofing agent formula and concrete formula are shown in Table 1.

[0030] Among them, the hydrophobic component is fluorine-containing polyhedral oligomeric silsesquioxane F-POSS and stearic acid hydroxychromium chloride in a mass ratio of 3:1; the water-reducing component is a polycarboxylic acid-based water reducer, and its weight The percentage concentration is 6%; the causing component is saponin; the dispersing component is heavy calcium carbonate.

[0031] Wherein the fly ash is low-calcium II grade, fineness is 8%, water demand ratio is 95%, and loss on ignition is 2%; described sand is the medium sand whose particle gradation area is the second zone, and the fineness modulus is 2.3, the mud content is 2%, and the mud content is 0.45%.

[0032] Wherein the epoxy resin is bisphenol A epoxy resin; the diluent used to dilute the epoxy resin is toluene, and the addition amount is 70phr-80phr.

[0033] The nano-calcium carbonate is composed of nano-calcium...

Embodiment 2

[0040] The waterproofing agent formula and concrete formula are shown in Table 1.

[0041] Among them, the hydrophobic component is fluorine-containing polyhedral oligomeric silsesquioxane F-POSS and stearic acid hydroxychromium chloride in a mass ratio of 4:1; The percentage concentration is 8%; the causing component is alkylbenzene sulfonic acid; the dispersing component is heavy calcium carbonate.

[0042] Wherein the fly ash is low calcium II grade, fineness is 10%, water demand ratio is 97%, and loss on ignition is 3.5%; described sand is the medium sand whose particle gradation area is the second zone, and the fineness modulus is 2.5, the mud content is 2.3%, and the mud content is 0.55%.

[0043] Wherein the epoxy resin is bisphenol A epoxy resin; the diluent used to dilute the epoxy resin is benzyl alcohol, and the addition amount is 70phr-80phr.

[0044]The nano-calcium carbonate is composed of nano-calcium carbonate with a particle size of 40nm and nano-calcium car...

Embodiment 3

[0051] The waterproofing agent formula and concrete formula are shown in Table 1.

[0052] Among them, the hydrophobic component is fluorine-containing polyhedral oligomeric silsesquioxane F-POSS and stearic acid hydroxychromium chloride in a mass ratio of 5:1; the water-reducing component is a polycarboxylic acid-based water reducer, and its weight The percentage concentration is 10%; the causing component is rosin thermal polymer; the dispersing component is heavy calcium carbonate.

[0053] Wherein the fly ash is low-calcium II grade, fineness is 13%, water demand ratio is 98%, and loss on ignition is 4.5%; described sand is the medium sand whose particle gradation area is the second zone, and the fineness modulus is 2.6, the mud content is 2.6%, and the mud content is 0.65%.

[0054] Wherein the epoxy resin is bisphenol A epoxy resin; the diluent used to dilute the epoxy resin is benzyl and xylene alcohol, and the addition amount is 70phr-80phr.

[0055] The nano-calcium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com