Method for synchronously preparing cellulose nanowhiskers and cellulose nanofibrils

A technology of nano-whiskers and nano-fibrils, which is applied in the post-treatment of cellulose pulp, the post-treatment modification of cellulose pulp, and the treatment of fiber raw materials. The time consumed, the initial temperature is high, and the effect of realizing full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Sulfuric acid concentration is 0.3wt%, namely sulfuric acid: water=mass ratio 0.3%;

[0035] Fiber concentration is 3wt%, namely fiber: water+fiber=mass ratio 3%;

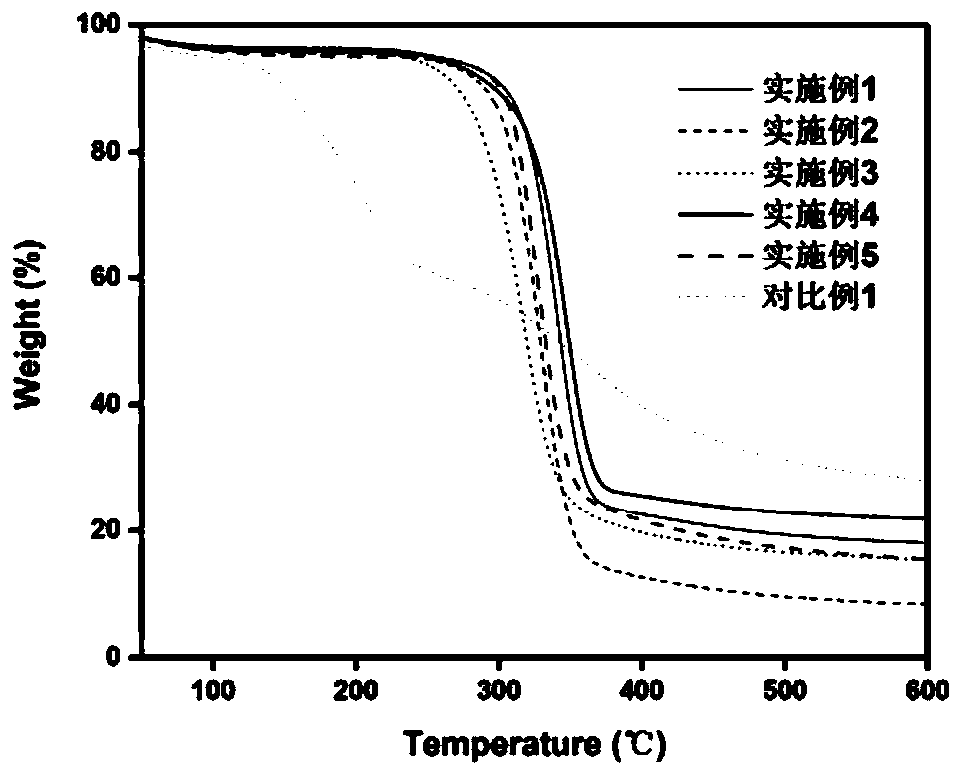

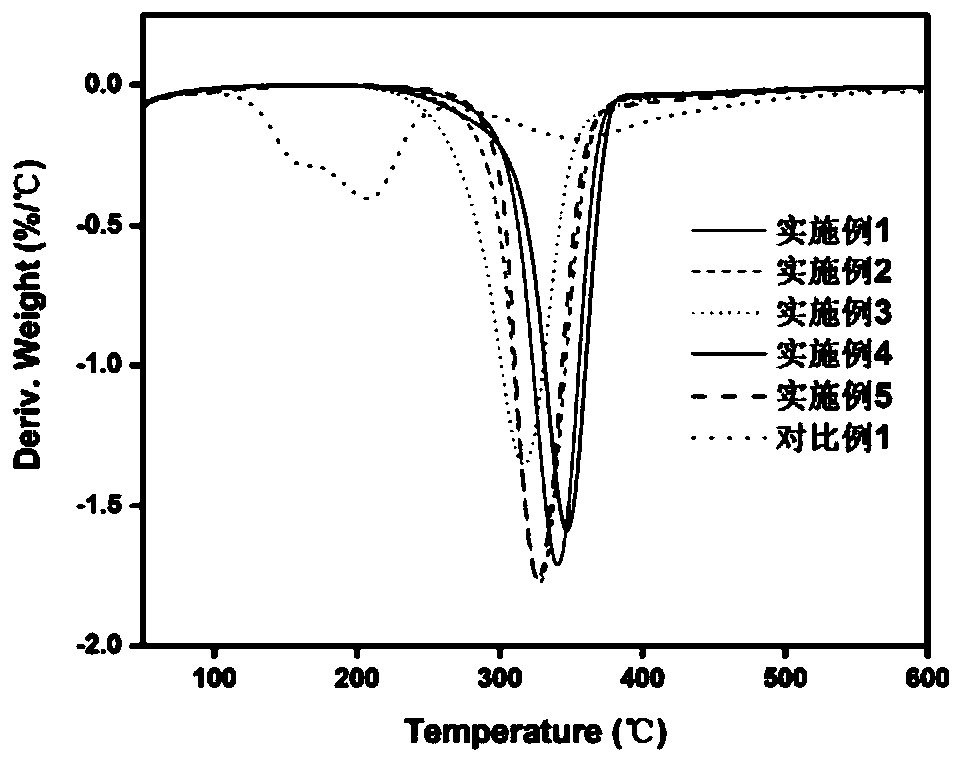

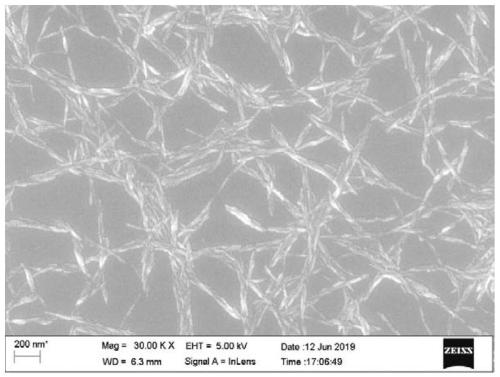

[0036] After mixing 1.5g of plant fiber slurry with 48.5mL of sulfuric acid solution, react at 160°C for 2 hours through a hydrothermal reactor, and start timing when the temperature is stable; After centrifugation at 10000rpm for 15min, the suspension of cellulose nano whiskers was obtained, and its morphology was characterized by scanning electron microscopy, as figure 2 As shown, the cellulose nano-whiskers are in a rod-like structure, and the length is mainly distributed between 200-400nm; through the size statistics of the suspension obtained under the conditions of Example 1 by the software Nano Measurer 1.2, the cellulose nano-whiskers are long for 150-400nm. 500nm, about 15-35nm in diameter (see image 3 ); the remaining cellulose solid residue was subjected to high-pressure homogenization for 6 t...

Embodiment 2

[0038] Sulfuric acid concentration is 0.3wt%, namely sulfuric acid: water=mass ratio 0.3%;

[0039] Fiber concentration is 4wt%, namely fiber: water+fiber=mass ratio 4%;

[0040] After mixing 2g of plant fiber slurry with 48mL of sulfuric acid solution, react at 160°C for 2 hours through a hydrothermal reactor, and start timing when the temperature is stable; After centrifugation for 15 minutes, the cellulose nano whisker suspension was obtained; the remaining cellulose solid residue was homogenized by high pressure for 6 times to obtain nanocellulose fibrils, such as Figure 4 As shown, the length is about 400nm-1200nm, and the yield is about 68.67%.

Embodiment 3

[0042] Sulfuric acid concentration is 0.35wt%, namely sulfuric acid: water=mass ratio 0.35%;

[0043] Fiber concentration is 4wt%, namely fiber: water+fiber=mass ratio 4%;

[0044] After mixing 2g of plant fiber slurry with 48mL of sulfuric acid solution, react at 150°C for 3 hours through a hydrothermal reactor, and start timing when the temperature is stable; After centrifugation for 15 minutes, a cellulose nanowhisker suspension was obtained; the remaining cellulose solid residue was homogenized by high pressure for 6 times to obtain nanocellulose fibrils, and the yield was about 67.42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com