Nickel-metal hydride battery sample preparation method for synchrotron radiation XRD in-situ test technology

A nickel-metal hydride battery, in-situ testing technology, applied in nickel storage battery, alkaline battery manufacturing, material analysis using wave/particle radiation, etc., can solve the problem of large battery compartment, messy XRD pattern, X-ray impermeability, etc. problems, to achieve the effect of advanced preparation technology, simple method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

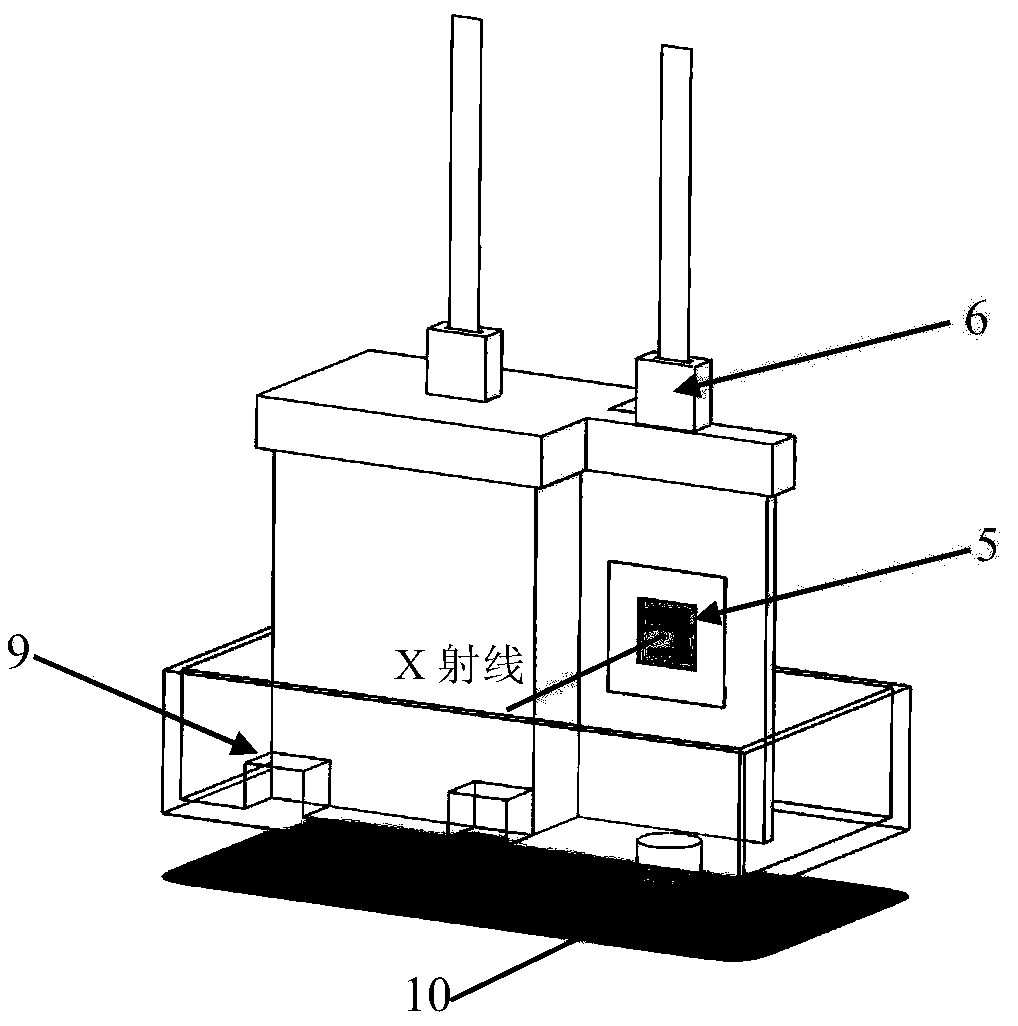

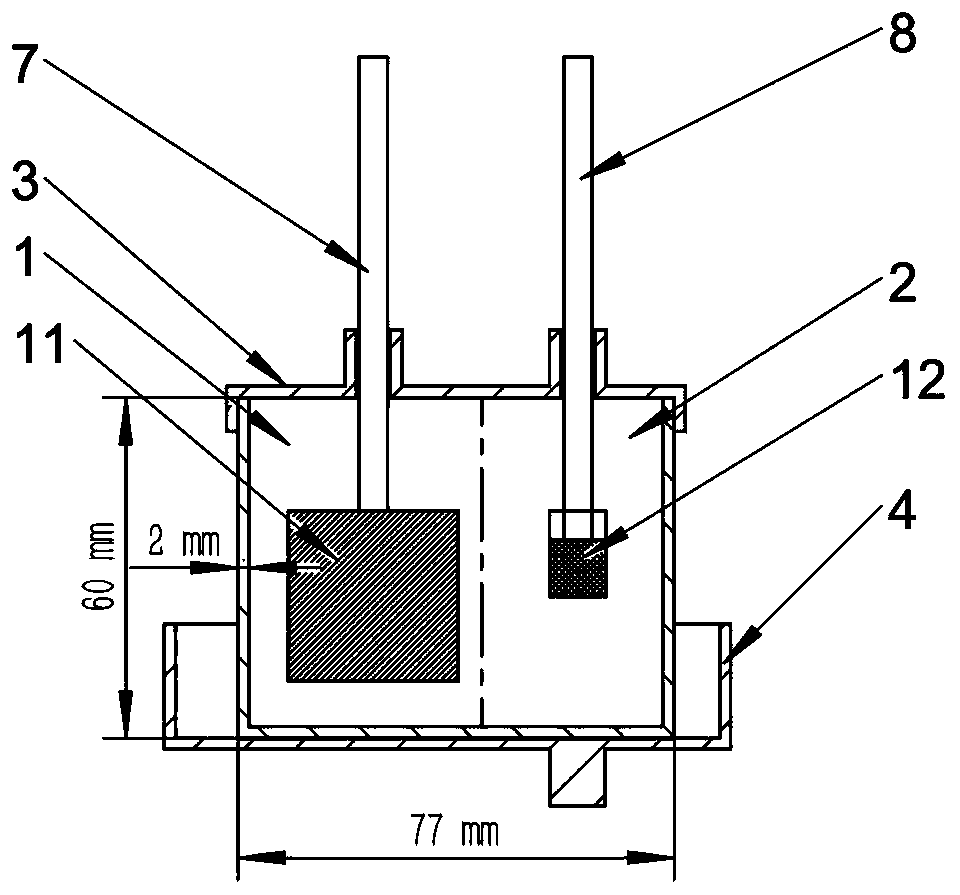

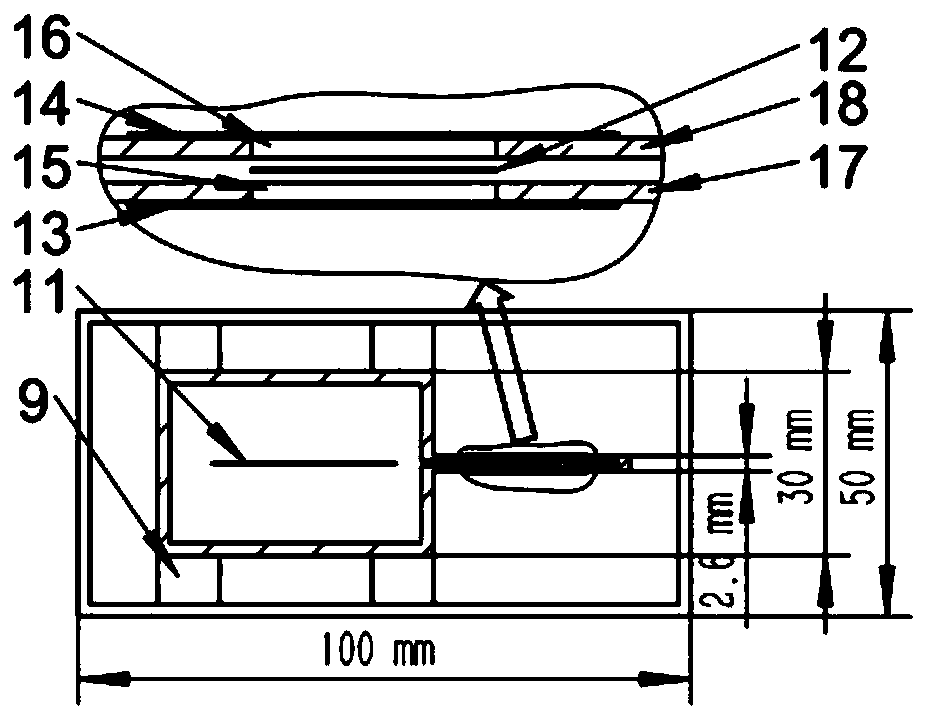

[0038] combine Figure 1~3 , the Ni-MH battery sample of the present invention comprises a battery main body and a base 4, the battery main body is placed on the base 4, the battery main body includes a positive electrode 11, a negative electrode 12, an electrolyte, a battery compartment and a hatch 3, and the hatch 3 is arranged on the battery On the top of the cabin, the hatch cover 3 is provided with a rectangular protrusion 6 for fixing the positive pole ear 7 and the negative pole ear 8. The positive pole ear 7 and the negative pole ear 8 pass through the rectangular protrusion 6 and are respectively connected to the positive pole 11 and the negative pole 12 located in the cabin. The negative electrodes 12 are arranged side by side on the same vertical plane. The interior of the battery compartment is composed of two connected (not closed) compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com