Anti-proton-irradiation InP-based HEMT device based on aluminum nitride/silicon nitride stacked structure and BCB bridge

A silicon nitride stack and proton irradiation technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, electric solid-state devices, etc., can solve complex processes, plasma damage, device and integrated circuit characteristic degradation, etc. problem, achieve the effect of reducing surface contamination and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

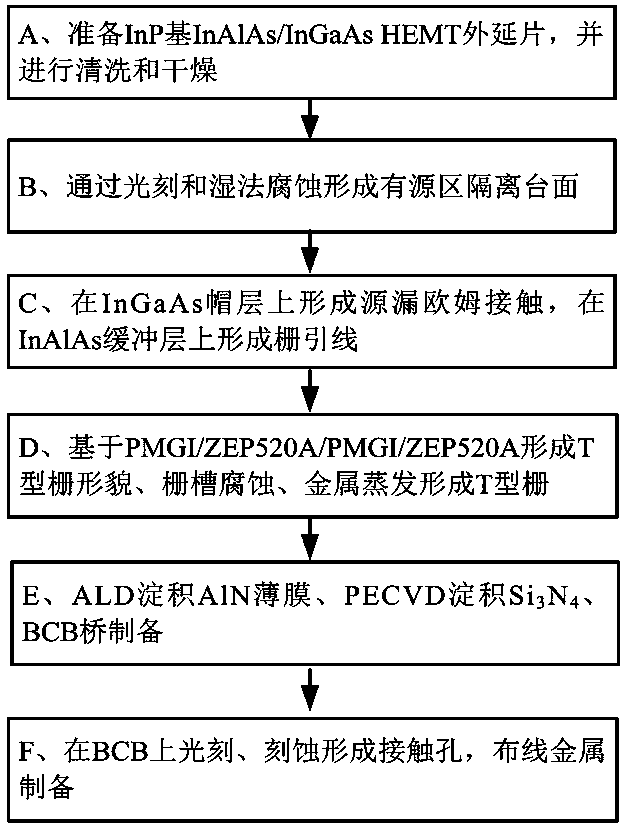

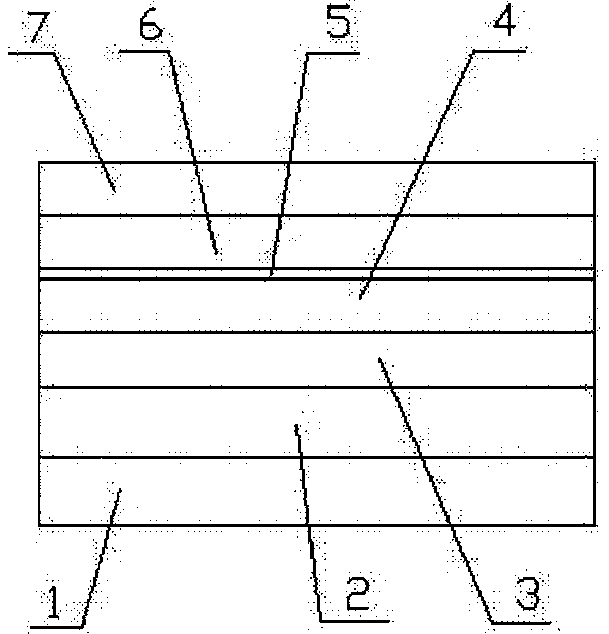

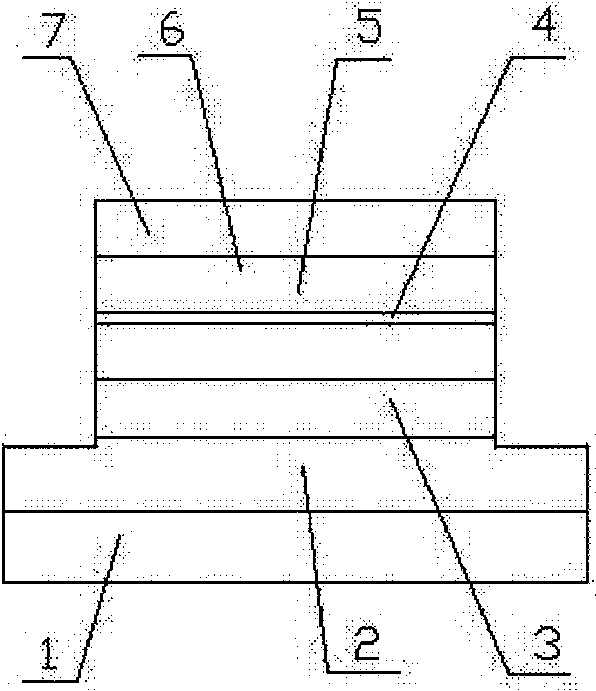

[0043] The cross-sectional structure of an anti-proton irradiation InP-based HEMT device based on aluminum nitride / silicon nitride stacked structure and BCB bridge is as follows: figure 1 shown. Its epitaxial structure from bottom to top is 100 μm thick InP substrate (InP Substrate), 500 nm thick InAlAs buffer layer (InAlAs Buffer), 15 nm thick InGaAs channel layer (InGaAs Channel), 3 nm thick InAlAs spacer (InAlAs Spacer), the doping concentration is 5×10 12 cm -2 Si surface doping layer (Si-Doping), 12nm thick InAlAs Schottky barrier layer (InAlAs Barrier), 30nm thick and doping concentration of 3×10 9 cm -2 InGaAs cap layer (InGaAs Cap); all InAlAs layers and InGaAs layers are lattice-matched with the InP substrate, the source isolation mesa is set on the InAlAs buffer layer, and the two sides of the highly doped InGaAs cap layer are respectively set There is a source ohmic contact metal and a drain ohmic contact metal, a grid is arranged on the InAlAs barrier layer b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com