Flaky manganese dioxide hollow frame structure material and preparation method and application thereof

A technology of manganese dioxide and frame structure, which is applied in the field of nanomaterials, can solve the problems of high price, poor cycle stability, and low specific capacity of positive electrode materials for zinc-ion batteries, and achieves controllable structure, uniform distribution of components, and excellent zinc The effect of ion battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Heat the carbon fiber cloth with nitric acid in an oil bath at 80°C for 4 hours, rinse it with deionized water until it becomes neutral, and dry it in vacuum at 60°C for 24 hours to obtain a hydrophilic carbon cloth;

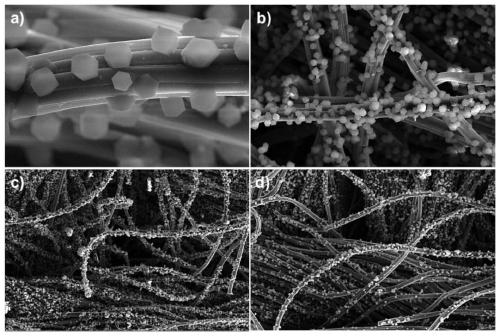

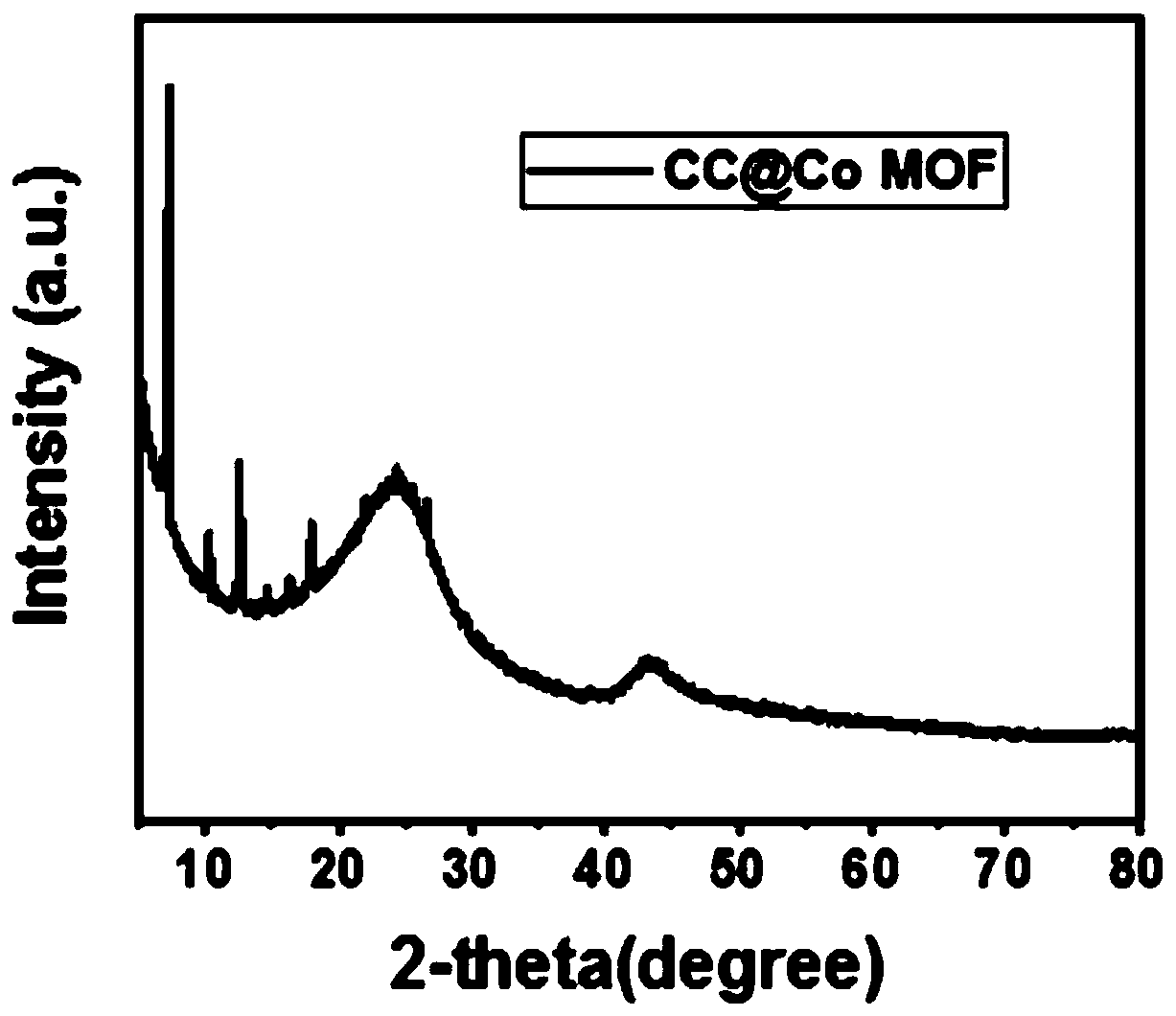

[0037] (2) At room temperature, add 40 mL of methanol solution containing 3.284 g of dimethylimidazole to 40 mL of methanol solution containing 1.308 g of cobalt nitrate hexahydrate, mix well under magnetic stirring for 6 hours, and add the above-mentioned hydrophilic carbon The cloth was reacted at room temperature for 12 h. After the reaction, it was rinsed with methanol three times; the obtained product was vacuum-dried at 60 °C for 24 h to obtain a three-dimensional Co-MOF / CC material; different magnifications of the three-dimensional Co-MOF / CC material The SEM picture is as follows figure 1 Shown; The XRD pattern of this three-dimensional Co-MOF / CC material is as follows figure 2 shown;

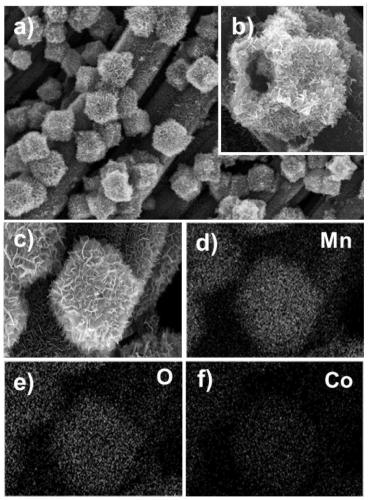

[0038] (2) At room temperature, add 36 mL of potassium ...

Embodiment 2

[0044] (1) Heat the carbon fiber cloth with nitric acid in an oil bath at 80°C for 6 hours, rinse it with deionized water until it becomes neutral, and dry it in vacuum at 60°C for 24 hours to obtain a hydrophilic carbon cloth;

[0045] (2) At room temperature, add 40 mL of methanol solution containing 3.284 g of dimethylimidazole to 40 mL of methanol solution containing 1.308 g of cobalt nitrate hexahydrate, mix well under magnetic stirring for 12 hours, add the above-mentioned hydrophilic carbon The cloth was reacted at room temperature for 12 h. After the reaction, it was washed with methanol three times; the obtained product was vacuum-dried at 60 °C for 24 h to obtain a three-dimensional Co-MOF / CC material;

[0046] (2) At room temperature, 6mg MnSO 4 Add 36mL aqueous solution of 100mL reaction kettle, add the above-mentioned Co-MOF / CC material, react in an oven at 180°C for 30min, rinse with deionized water three times, and the obtained product is vacuum-dried at 60°C fo...

Embodiment 3

[0048] (1) Heat the carbon fiber cloth with nitric acid in an oil bath at 80°C for 5 hours, rinse it with deionized water until neutral, and dry it in vacuum at 60°C for 24 hours to obtain a hydrophilic carbon cloth;

[0049] (2) At room temperature, add 40 mL of methanol solution containing 3.284 g of dimethylimidazole to 40 mL of methanol solution containing 1.308 g of anhydrous ferric chloride, mix well under magnetic stirring for 10 hours, add the above-mentioned hydrophilic The carbonized carbon cloth was reacted at room temperature for 12 h. After the reaction, it was washed with methanol three times; the obtained product was vacuum-dried at 60 °C for 24 h to obtain a three-dimensional Fe-MOF / CC material;

[0050] (2) At room temperature, add 36 mL of potassium permanganate solution with a concentration of 5 mmol / L into a 100 mL reaction kettle, add the above-mentioned Co-MOF / CC material, react in an oven at 100 °C for 180 min, and use deionized water After washing 3 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com