Carbon nanotube-containing carbon shell-coated silicon negative electrode material and preparation method thereof

A technology of carbon nanotubes and carbon nanotubes is applied in the field of preparation of carbon polyhedron-coated silicon negative electrode materials, and can solve the problems of uneven coating and low degree of graphitization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step (1) Dissolve 1.97g of dimethylimidazole and 1.76g of cobalt nitrate hexahydrate in 20ml of absolute ethanol and 20ml of methanol solution respectively until the two substances are completely dissolved.

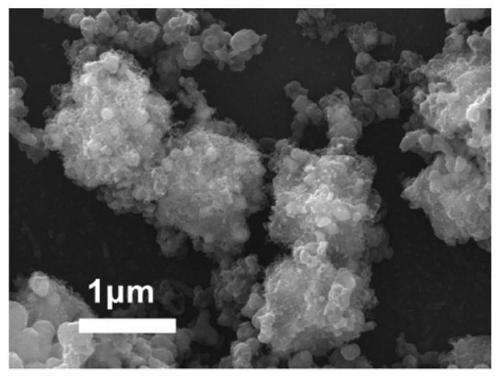

[0022] Step (2) Add 50.0mg of silicon powder (particle size is 100nm) into the above-mentioned mixed solution dissolved in cobalt nitrate hexahydrate, stir until the silicon powder is evenly dispersed in the mixed solution, and then dissolve the dimethylimidazole Add the mixed solution, let it stand for 24 hours, and collect it by centrifuging and drying for later use.

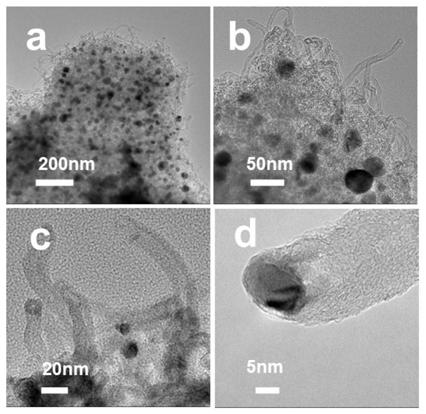

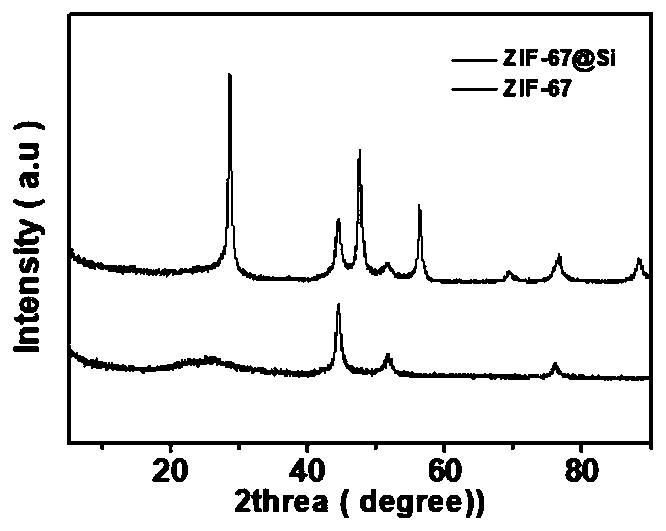

[0023] Step (3) Put the sample collected above in a corundum boat, put it into a tube furnace, and heat it at 2°C / min to 350°C for 1.5h under an atmosphere of argon-hydrogen mixture (10% hydrogen), and then continue The temperature was raised to 600°C and kept for 3.5 hours. After the sample was cooled to room temperature, it was added to 50ml of 1mol / L sulfuric acid solution, stirred for 6 hours, ...

Embodiment 2

[0026] Step (1) Dissolve 1.97g of dimethylimidazole and 1.76g of cobalt nitrate hexahydrate in 20ml of absolute ethanol and 20ml of methanol respectively until the two substances are completely dissolved.

[0027] Step (2) Add 50.0mg of silicon powder (particle size is 100nm) into the above-mentioned mixed solution dissolved in cobalt nitrate hexahydrate, stir until the silicon powder is evenly dispersed in the mixed solution, and then dissolve the dimethylimidazole Add the mixed solution, let it stand for 24 hours, and collect it by centrifuging and drying for later use.

[0028] Step (3) Put the sample collected above in a corundum boat, put it into a tube furnace, and heat it at 2°C / min to 350°C for 1.5h under an atmosphere of argon-hydrogen mixture (10% hydrogen), and then continue The temperature was raised to 700°C and kept for 3.5 hours. After the sample was cooled to room temperature, it was added to 50ml of 1mol / L sulfuric acid solution, stirred for 6 hours, and final...

Embodiment 3

[0031] Step (1) Dissolve 1.97g of dimethylimidazole and 1.76g of cobalt nitrate hexahydrate in 20ml of absolute ethanol and 20ml of methanol respectively until the two substances are completely dissolved.

[0032] Step (2) Add 50.0mg of silicon powder (particle size is 100nm) into the above-mentioned mixed solution dissolved in cobalt nitrate hexahydrate, stir until the silicon powder is evenly dispersed in the mixed solution, and then dissolve the dimethylimidazole Add the mixed solution, let it stand for 24 hours, and collect it by centrifuging and drying for later use.

[0033] Step (3) Put the sample collected above in a corundum boat, put it into a tube furnace, and heat it at 2°C / min to 350°C for 1.5h under an atmosphere of argon-hydrogen mixture (10% hydrogen), and then continue The temperature was raised to 800°C and kept for 3.5 hours. After the sample was cooled to room temperature, it was added to 50ml of 1mol / L sulfuric acid solution, stirred for 6 hours, and final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com