Method for extracting lithium from water with high magnesium-lithium ratio and preparing lithium carbonate

A high magnesium-lithium ratio, lithium carbonate technology, applied in lithium carbonate;/acid carbonate, chemical instruments and methods, heating water/sewage treatment, etc., to avoid incomplete precipitation of magnesium ions, high purity, Larger effect of avoiding lithium loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

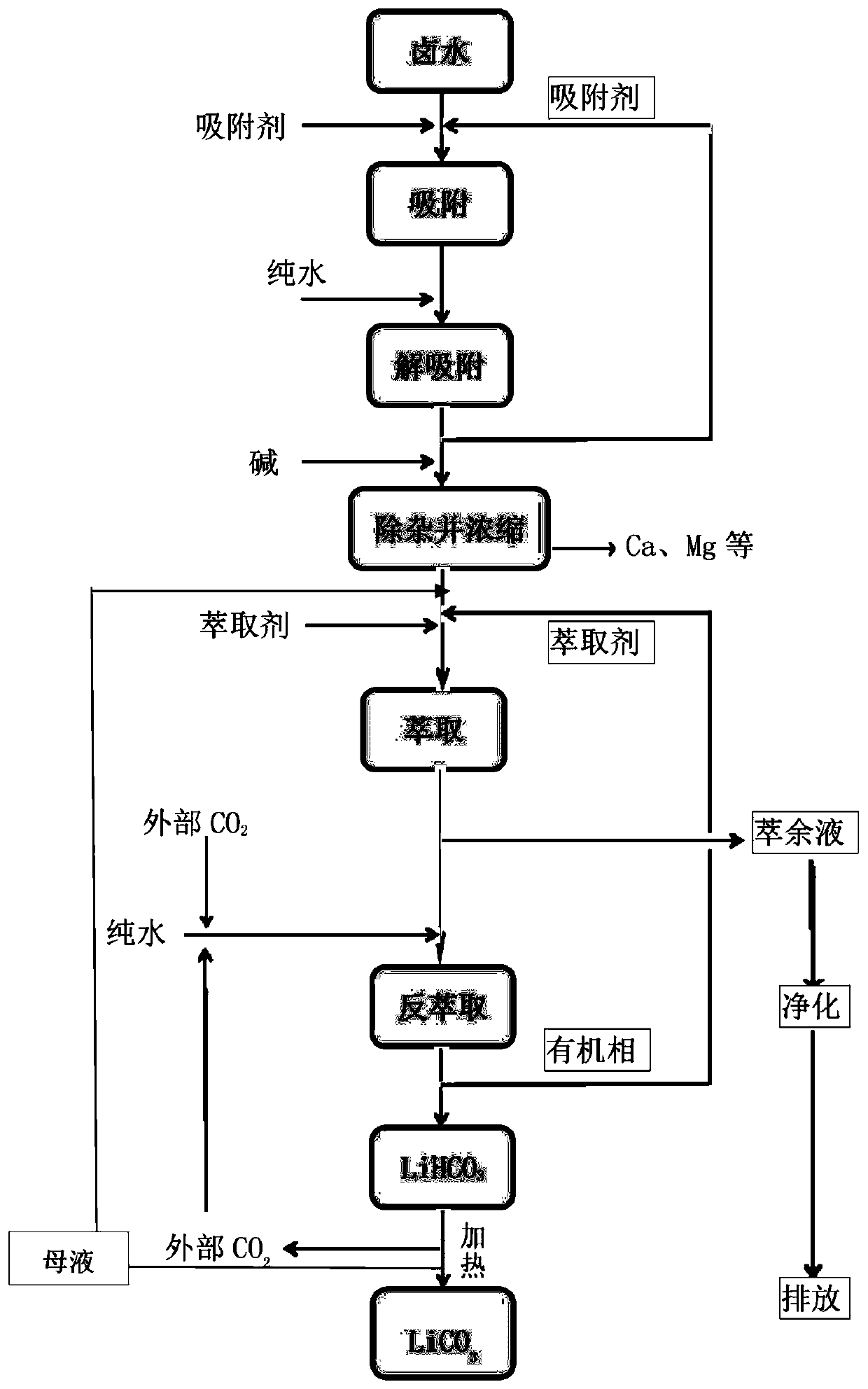

Method used

Image

Examples

Embodiment 1

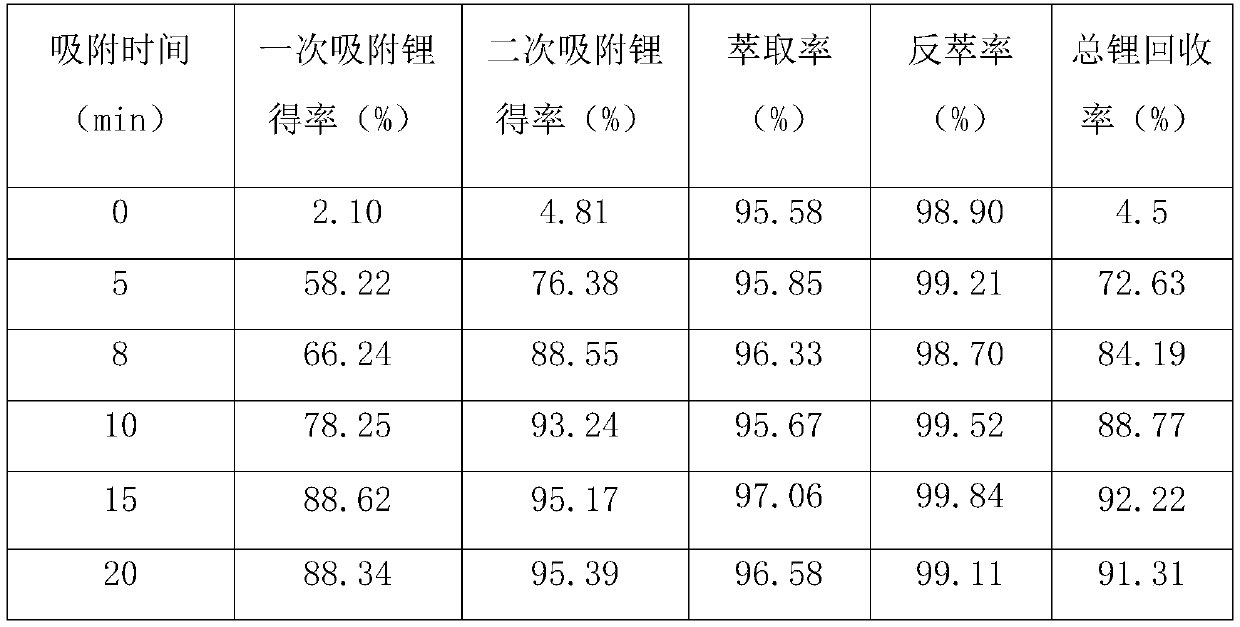

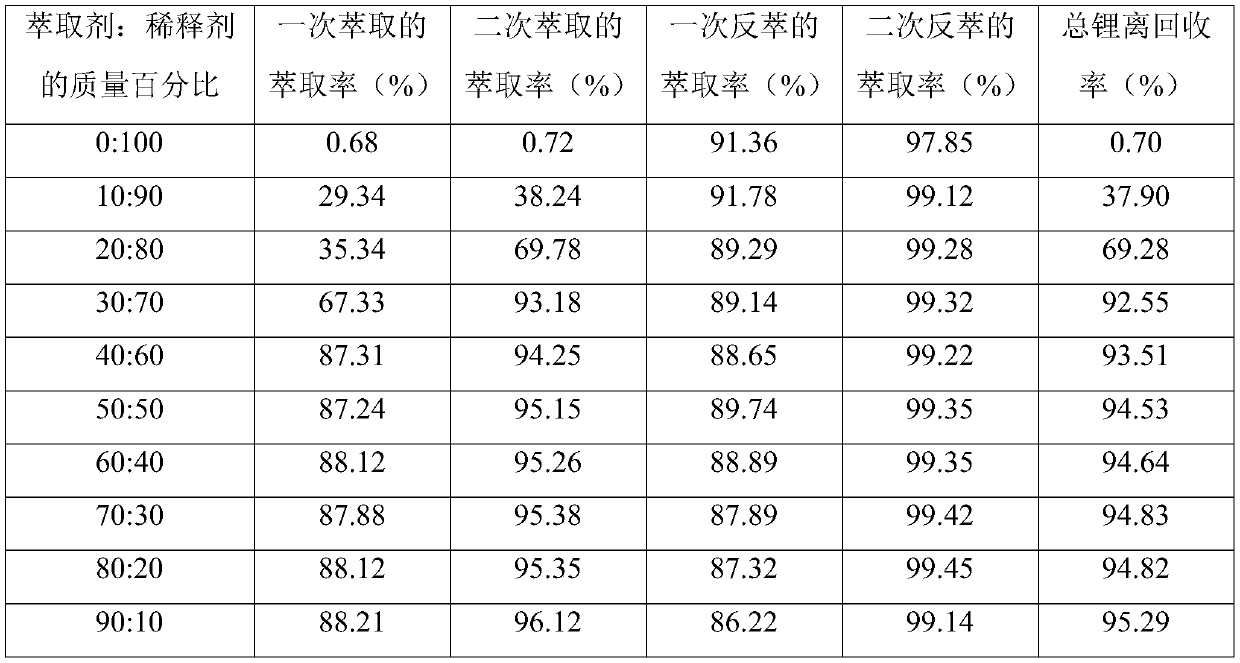

[0032] (1) Adsorption process: select Qinghai Salt Lake brine with a lithium ion content of 0.15g / L (containing Mg 2+ 、Na + 、K + 、Cs + , Pb + , Cl - , SO 4 2- and other impurities), the pH value of which is 4.0, the lithium-containing water is passed into the device containing manganese-based adsorbents, and lithium and a small amount of impurity magnesium are separated from the water by adsorption, and the adsorption time is 15 minutes;

[0033] (2) Desorption process: Pass the saturated manganese-based adsorbent into pure water, then pass pure water and carbon dioxide into the system as the eluent, control the desorption temperature at 30°C, and the desorption time for 15 minutes. The ions on the adsorbent are dissolved in water to obtain a desorption solution containing 0.135 g / L of lithium ions;

[0034] (3) Remove impurities and concentrate: add a certain amount of NaOH to the desorption solution, adjust the desorption solution to a pH value of 7.6, and remove most...

Embodiment 2

[0042] (1) Adsorption process: select old salt lake salt brine with a lithium ion content of 0.075g / L, and its pH value is 4.5, pass the lithium-containing water into the device containing aluminum-based adsorbents, and absorb lithium and a small amount of impurities by adsorption Magnesium is separated from water; the adsorption time is 10min;

[0043] (2) Desorption process: put the saturated aluminum-based adsorbent into pure water, add an appropriate eluent, the eluent is pure water at 40°C, control the desorption temperature at 40°C, and the desorption time for 10 minutes. The ions on the adsorbent are dissolved in water to obtain a desorption solution containing 0.045 g / L of lithium ions;

[0044] (3) Remove impurities and concentrate: add a certain amount of NaOH to the desorption solution, adjust the desorption solution to a pH value of 8, and remove most of the impurity ions such as magnesium, calcium, and barium in the desorption solution; use MVR three-effect evapor...

Embodiment 3

[0052] (1) Adsorption process: select old salt lake salt brine with a lithium ion content of 0.075g / L, and its pH value is 4.5, pass the lithium-containing water into the device containing aluminum-based adsorbents, and absorb lithium and a small amount of impurities by adsorption Magnesium is separated from water; the adsorption time is 10min;

[0053] (2) Desorption process: put the saturated aluminum-based adsorbent into pure water, add an appropriate eluent, the eluent is hydrochloric acid with a concentration of 0.1%, control the desorption temperature at 40°C, and the desorption time for 10 minutes , the ions adsorbed on the adsorbent are dissolved in water to obtain a desorption solution containing 0.045 g / L of lithium ions;

[0054] (3) Remove impurities and concentrate: add a certain amount of NaOH to the desorption solution, adjust the desorption solution to a pH value of 8, and remove most of the impurity ions such as magnesium, calcium, and barium in the desorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com