Method for rare earth treatment of Al2O3 inclusions in full process of cast rolling of refined ultra-low-carbon IF steel

An ultra-low carbon and inclusion technology, applied in the field of steelmaking, can solve the problems of affecting the continuity of the structure, removing steel, stamping and cracking of products, etc., and achieve the effect of reducing surface defects and stamping cracking problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

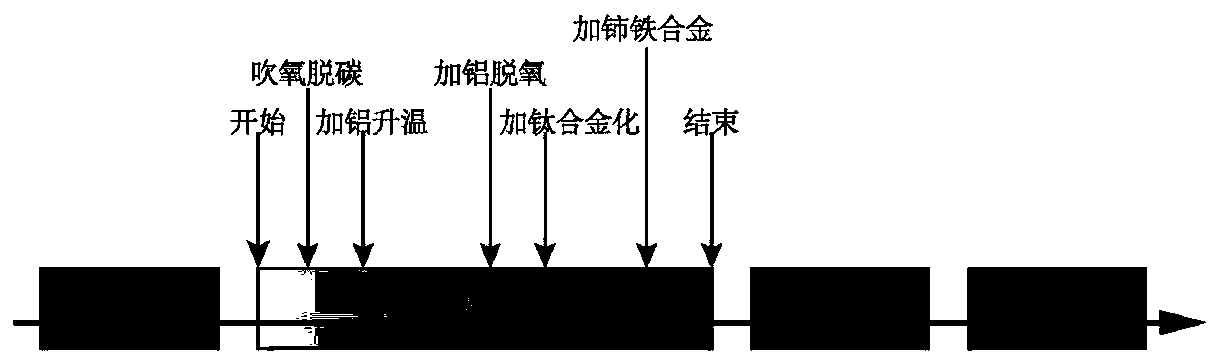

[0026] In the hot continuous rolling production line, the comparative test of the production of phosphorus-containing strengthened IF steel in adjacent heats of co-casting is carried out. The production process flow and the timing of rare earth addition are as follows: figure 1 shown. During RH vacuum treatment, the ultimate vacuum degree is ≤0.106Kpa, and the vacuum treatment time is 30 minutes in total. Because rare earths have strong oxidizing properties, in order to avoid the oxidation of oxygen brought in by other alloys during the alloying process, and to ensure the effective boron content in the steel, after aluminum deoxidation, the alloy addition sequence in the RH vacuum treatment process is Mn Iron, Ti iron, Nb iron, boron iron. 110 kg of rare earth cerium-iron alloy (with a Ce content of 10%) was added when circulating for 3 minutes after the alloying was completed. After the RH treatment, the sedation time is longer than 15 minutes to ensure that the inclusions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com