Application of glucose oxidase combined with peroxidase in mycotoxin detoxification

A technology of glucose oxidase and peroxidase, applied in food science and other fields, can solve the problem that manganese peroxidase cannot degrade toxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

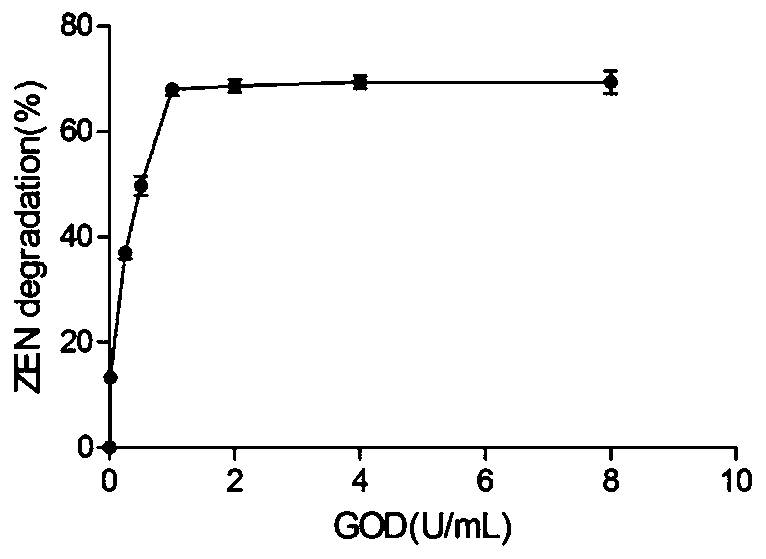

[0031] Example 1 Combined application of glucose oxidase GOD and dye decoloring peroxidase DyP on the degradation effect of zearalenone

[0032] The dye decoloring peroxidase DyP is dissolved in sodium phosphate buffer (0.1M, pH 7.0), and 1 mL of dye decoloring peroxidase DyP solution (enzyme activity 5U / mL) is added to 0.0125, 0.025, 0.5, 1, 2, 4 and 8U / mL glucose oxidase GOD, then add 200μM glucose and ZEN, the concentration of ZEN reaches 10μg / mL; take the system without dye decoloring peroxidase DyP as control; react at 37℃ for 3h , 1mL methanol was added to terminate the reaction, and the ZEN content was detected by high performance liquid chromatography.

[0033] The result is figure 1 As shown, as the concentration of glucose oxidase GOD increases, the degradation rate of dye decoloring peroxidase DyP to ZEN increases. When the concentration of GOD is 1U / mL, the degradation rate of dye decoloring peroxidase DyP to ZEN reaches 68. %.

Embodiment 2

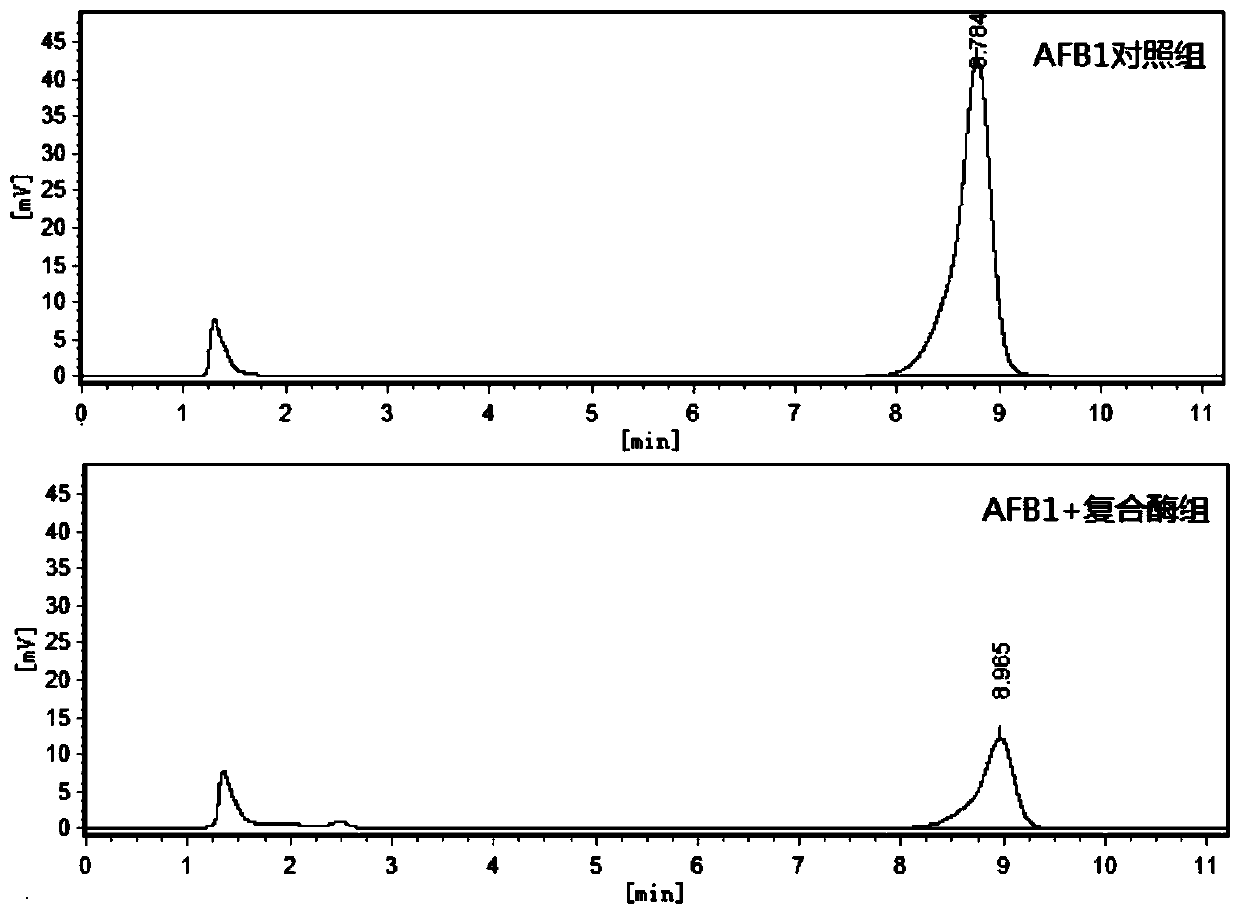

[0034] Example 2 Preparation method and application of a composite enzyme for degrading mycotoxins

[0035] Weigh a certain amount of glucose oxidase GOD and horseradish peroxidase HRP and mix them in a ratio of 1:3 by mass to obtain a composite enzyme that degrades mycotoxins; then use the prepared composite enzyme to degrade aflatoxin B1 (AFB1), dissolve 1mg of complex enzyme in 1mL sodium citrate buffer (0.1M, pH 6) reaction system, add 100μM glucose, then add AFB1, AFB1 concentration is 1μg / mL, react at 37℃ for 12h, add 1mL The reaction was terminated by methanol; the system without compound enzyme was used as a control; the content of AFB1 was detected by high performance liquid chromatography.

[0036] The results showed that the compound enzyme degrading mycotoxins reacted with 1μg / mL AFB1 for 12h, and the degradation rate of AFB1 was 82% ( figure 2 ).

Embodiment 3

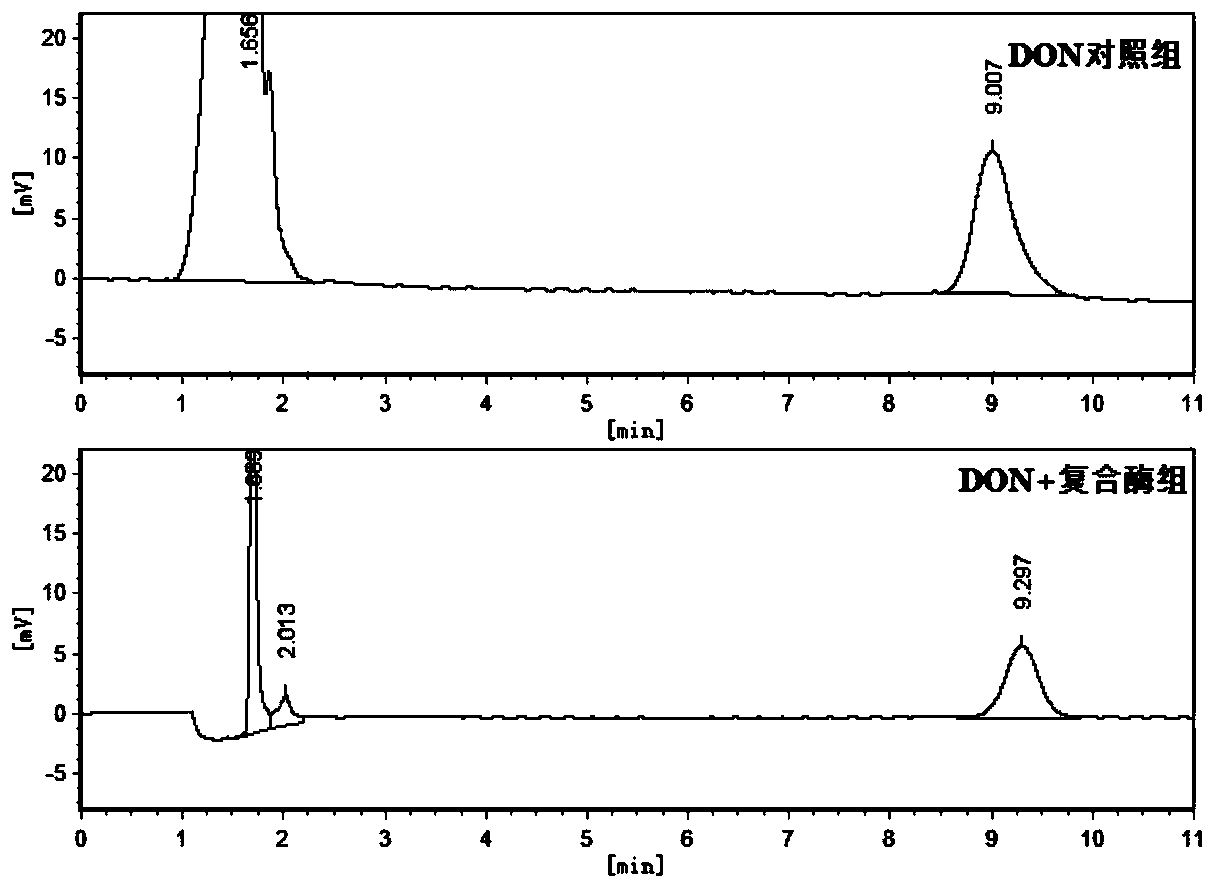

[0037] Example 3 Preparation method and application of a composite enzyme for degrading mycotoxins

[0038] Weigh a certain amount of glucose oxidase GOD and lactoperoxidase LPO, mix them in a ratio of 1:4 by mass, and then add mediator ABTS that accounts for 1% of the amount of enzyme to prepare a composite enzyme that degrades mycotoxins; The obtained complex enzyme is used to degrade vomitin (DON). Dissolve 1 mg of complex enzyme in 1mL sodium citrate buffer (0.1M, pH5.0) reaction system, add 200μM glucose, and then add DON, the concentration of DON is 20μg / mL , React at 37°C for 24h, add 1mL methanol to terminate the reaction; take the system without adding complex enzyme as a control; use high performance liquid chromatography to detect the DON content.

[0039] The results showed that the compound enzyme degrading mycotoxins reacted with 20μg / mL DON for 24h, and its degradation rate of DON was 63% ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com