Preparation method and application of mesoporous silica material

A technology of mesoporous silica and bisdecyl dimethyl ammonium chloride, applied in chemical instruments and methods, alkali metal oxides/hydroxides, silicon compounds, etc. The process is complicated, the process is complex and other problems, to achieve the effect of obvious effect, simple process, and prolong the volatilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

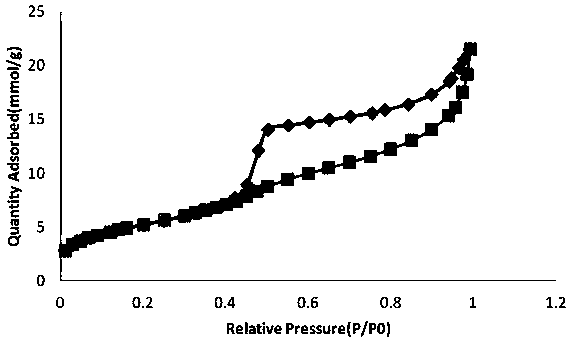

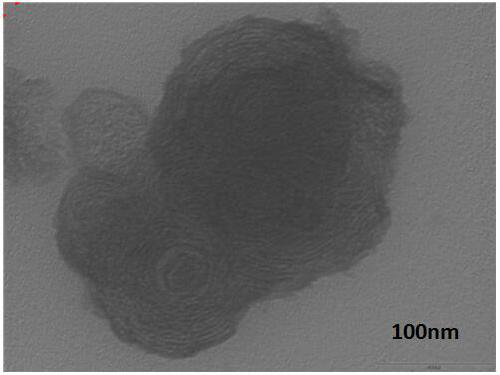

[0019] According to tetraethyl orthosilicate: didecyl dimethyl ammonium chloride: water molar ratio is 1:0.25:240, weigh 12.9g of didecyl dimethyl ammonium chloride with a content of 70%, add to Stir and dissolve the mixed solution in 432g distilled water, with a concentration of 9molL -1 KOH solution to adjust the pH of the solution to 10, slowly add 20.833g TEOS dropwise under stirring, stir at room temperature for 8 hours, seal and age in an oven at 80°C for 6 hours, filter, wash with water and ethanol, and dry at 120°C for 4 hours to obtain a synthetic product. Raw powder, calcined the raw powder at 450°C for 1 hour to obtain a pore diameter of 4.5nm and a specific surface area of 1000cm 2 / g pore volume is 0.3cm 3 / g mesoporous silica material.

[0020] Weigh 5g of the above-mentioned mesoporous silica into a beaker, add 10g of rose essence, ultrasonicate at room temperature for 30min at 250w power to disperse the powder evenly, then vibrate for 2 hours on a constant ...

Embodiment 2

[0023] Carry out according to ethyl orthosilicate: double decyl dimethyl ammonium chloride: water molar ratio is 1: 0.125: 240, weigh 6.45g of double decyl dimethyl ammonium chloride with a content of 70%, add to Stir and dissolve the mixed solution in 432g distilled water, with a concentration of 9molL -1 KOH solution to adjust the pH value of the solution to 12, slowly add 20.833g TEOS dropwise under stirring, stir at room temperature for 6 hours, seal and age in an oven at 60°C for 4 hours, filter, wash with water and ethanol, and dry at 120°C for 1 hour to obtain Synthetic raw powder, the raw powder is calcined at 550°C for 1 hour to obtain a pore diameter of 5nm and a specific surface area of 850cm 2 / g pore volume is 0.8cm 3 / g mesoporous silica material.

[0024] Weigh 4g of the above-mentioned mesoporous silica into a beaker, add 8g of rose essence, ultrasonicate at room temperature for 20min at a power of 250w to disperse the powder evenly, then vibrate for 2 hour...

Embodiment 3

[0026] According to tetraethyl orthosilicate: didecyl dimethyl ammonium chloride: water molar ratio is 1:0.1:240, weigh 6.4g of didecyl dimethyl ammonium chloride with a content of 70%, add to Stir and dissolve the mixed solution in 432g distilled water, with a concentration of 9molL -1 KOH solution to adjust the pH value of the solution to 10, slowly add 20.833g TEOS dropwise under stirring, stir at room temperature for 7 hours, seal and age in an oven at 70°C for 5 hours, filter, wash with water and ethanol, and dry at 120°C for 2 hours to obtain Synthetic raw powder, the raw powder is calcined at 500°C for 1 hour to obtain a pore diameter of 8nm and a specific surface area of 400cm 2 / g Pore volume is 1.0cm 3 / g mesoporous silica material.

[0027] Weigh 1g of the above-mentioned mesoporous silica into a beaker, add 5g of rose essence, ultrasonicate at room temperature for 10min at 250w power to disperse the powder evenly, then vibrate for 2 hours on a constant temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com