Surface-enhanced Raman scattering substrate based on metal nanobowl and its preparation method

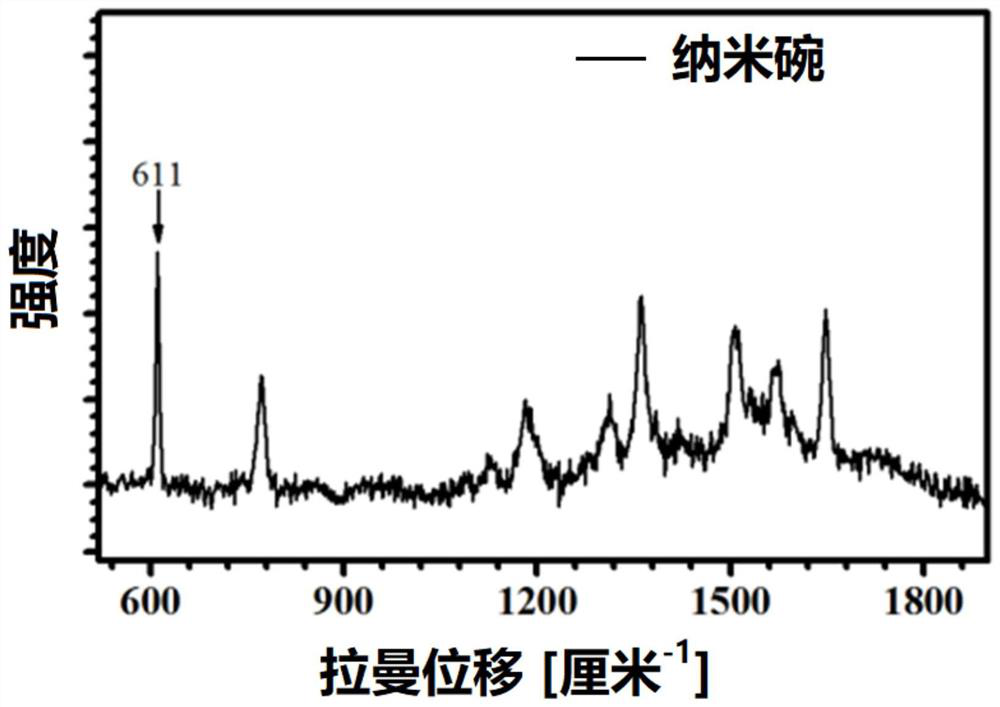

A surface-enhanced Raman, metal nanotechnology, applied in Raman scattering, material excitation analysis, instruments, etc., can solve the problems of incapability of large-area preparation, limited wide application, high cost, etc., and achieve high surface-enhanced Raman scattering effect. , good repeatability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Based on the preparation method of the surface-enhanced Raman scattering substrate of metal nano bowls, the steps are as follows:

[0026] (1) Preparation of polymer nano bowls;

[0027] Firstly, the mixed film of polystyrene and polymethyl methacrylate with a mass ratio of polystyrene to polymethyl methacrylate of 1:9 was soaked in a mixed solvent for 100 minutes, and the mixed solvent was 2:1:5 by volume. It is composed of methyl ethyl ketone, acetone and water to obtain polymer nanospheres, and then the polymer nanospheres are soaked in cyclohexane for 20 minutes, the polystyrene is removed to obtain polymer nanobowls, and finally they are taken out and dried with compressed gas;

[0028] (2) Taking the polymer nano bowl as the base, and vertically sputtering the metal film on it;

[0029] The process parameters of vertical sputtering are: current 20A, time 4s;

[0030] The metal film is nano silver film.

[0031] The final surface-enhanced Raman scattering substr...

Embodiment 2

[0044] Based on the preparation method of the surface-enhanced Raman scattering substrate of metal nano bowls, the steps are as follows:

[0045] (1) Preparation of polymer nano bowls;

[0046] First, the polystyrene and polymethyl methacrylate mixed film with a mass ratio of polystyrene to polymethyl methacrylate of 9:1 was soaked in a mixed solvent for 5 minutes, and the mixed solvent was 2:1:8 by volume. The polymer nanospheres were prepared by immersing the polymer nanospheres in cyclohexane for 12 minutes, removing the polystyrene to obtain the polymer nanobowls, and finally taking them out and drying them with compressed gas;

[0047] (2) Taking the polymer nano bowl as the base, and vertically sputtering the metal film on it;

[0048] The process parameters of vertical sputtering are: current 15A, time 3s;

[0049] The metal film is a nano-gold film.

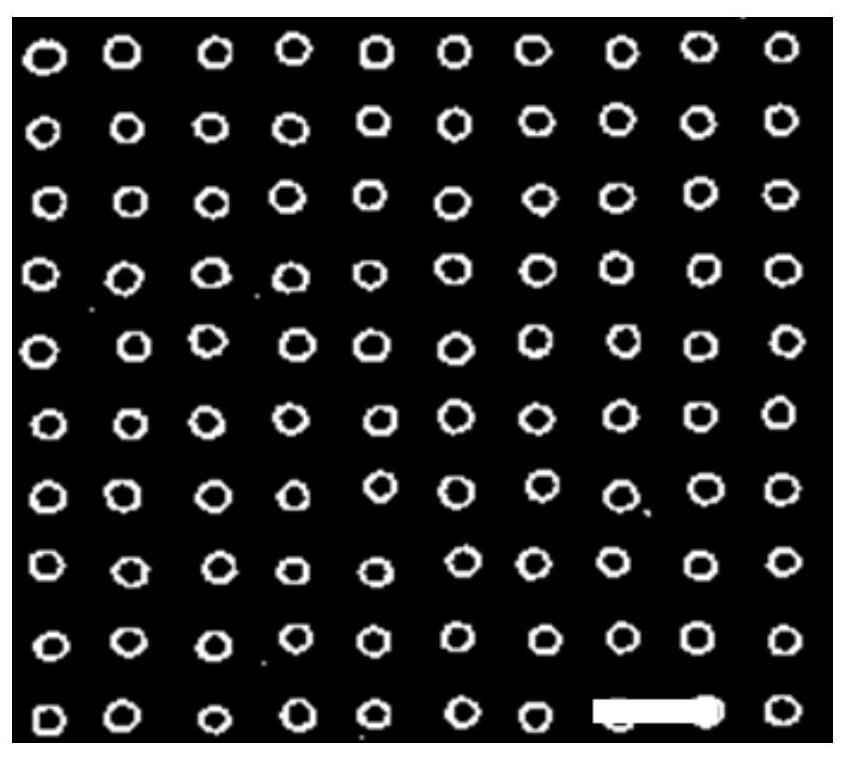

[0050] The final surface-enhanced Raman scattering substrates based on metal nanobowls are as follows: figure 1 As ...

Embodiment 3

[0053] Based on the preparation method of the surface-enhanced Raman scattering substrate of metal nano bowls, the steps are as follows:

[0054] (1) Preparation of polymer nano bowls;

[0055] Firstly, the mixed film of polystyrene and polymethyl methacrylate with a mass ratio of polystyrene to polymethyl methacrylate of 1:2 was soaked in a mixed solvent for 50 minutes, and the mixed solvent was 2:1:6 by volume. It is composed of methyl ethyl ketone, acetone and water to obtain polymer nanospheres, and then the polymer nanospheres are soaked in cyclohexane for 18 minutes, the polystyrene is removed to obtain polymer nanobowls, and finally they are taken out and dried with compressed gas;

[0056] (2) Taking the polymer nano bowl as the base, and vertically sputtering the metal film on it;

[0057] The process parameters of vertical sputtering are: current 22A, time 6s;

[0058] The metal film is a nano-gold film.

[0059] The final surface-enhanced Raman scattering substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com