Preparation method of absorption type flexible transparent electromagnetic shielding film and product

An electromagnetic shielding and absorbing technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of difficulty in reconciling shielding effectiveness and light transmittance, secondary electromagnetic radiation pollution, and complicated electromagnetic environment, and achieve excellent electromagnetic absorption Wave ability, overcome the poor bending fatigue characteristics, and avoid the effect of secondary electromagnetic radiation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

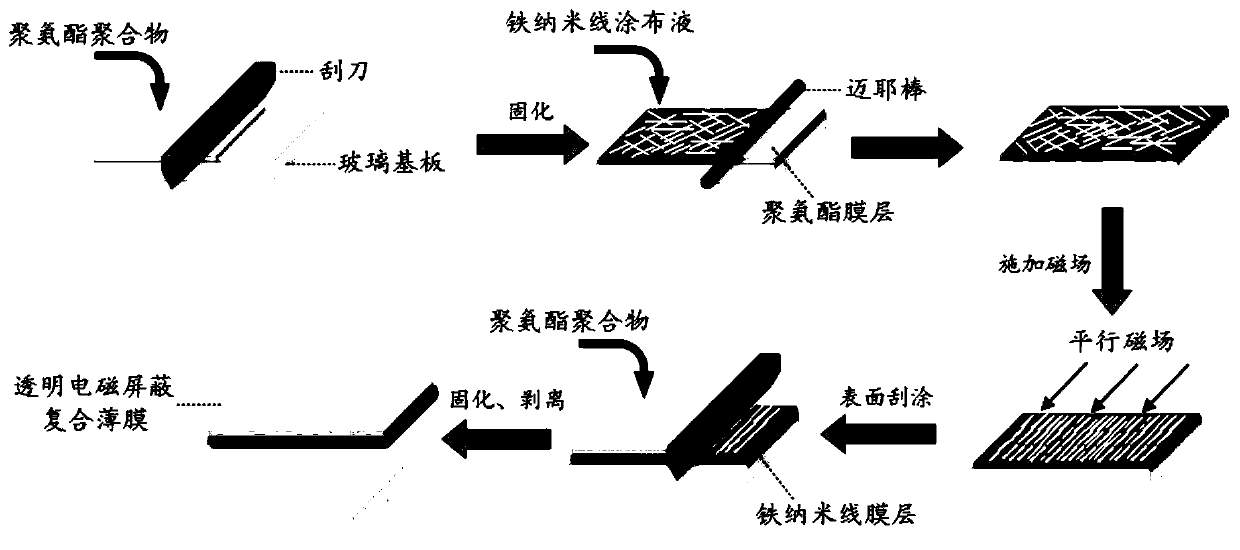

[0039] Prepare an absorbing flexible transparent electromagnetic shielding film, the schematic diagram of the preparation process is as follows figure 1 Shown:

[0040] (1) After the glass substrate is ultrasonically cleaned with a cleaning agent, it is alternately rinsed with deionized water and absolute ethanol for 3 times, and then dried with high-purity nitrogen, and set aside;

[0041] (2) Scrape-coat polyurethane with a viscosity of 1000mPa.s on the glass substrate treated in step (1) and solidify at 80° C. for 0.5 h to obtain a flexible transparent polymer film layer I with a thickness of 150 μm;

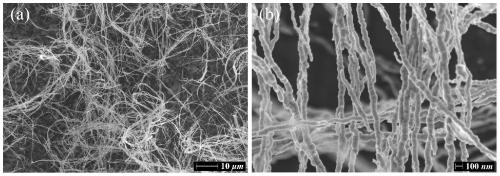

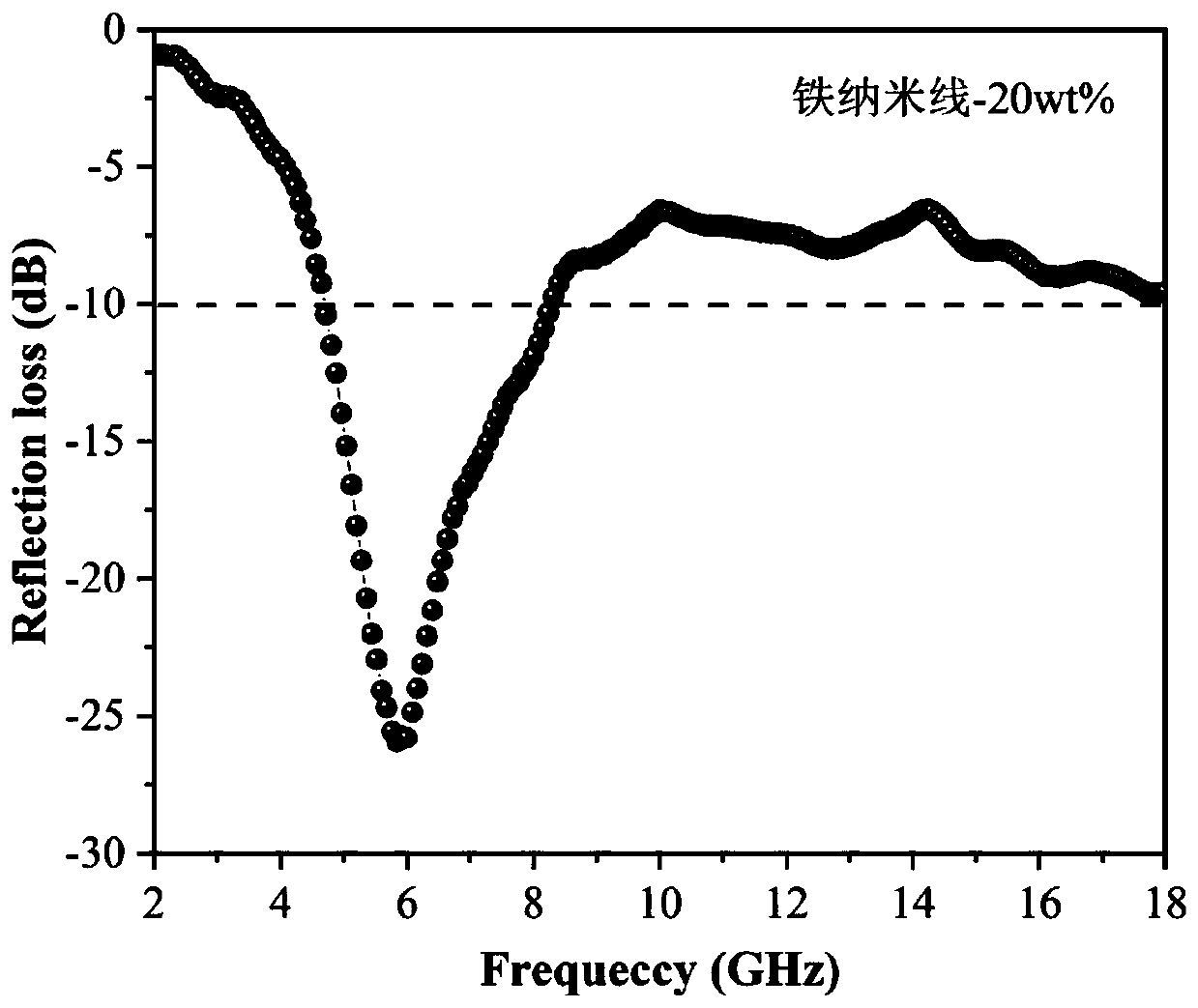

[0042] (3) Mix hydroxypropyl methylcellulose and deionized water at a mass ratio of 3.5:1, and use a shaker to mix at a speed of 120r / min for 1 hour to form solution A; mix Sago-dispersant 9760 and deionized water by mass Mix at a ratio of 1:9, and use a shaker to mix at a speed of 100r / min for 1 hour to form solution B; the iron nanowires with an average wire diameter of 80...

Embodiment 2

[0045] Preparation of an Absorbent Flexible Transparent Electromagnetic Shielding Film

[0046] (1) After ultrasonically cleaning the polyethylene terephthalate plastic substrate with a cleaning agent, rinse it alternately with deionized water and absolute ethanol for 5 times, then dry it with high-purity argon, and set aside;

[0047] (2) Roll-coat polydimethylsiloxane with a viscosity of 200mPa.s on the plastic substrate treated in step (1) with a Meyer rod and cure at 40°C for 45min to obtain a flexible film with a thickness of 150μm. Transparent polymer film layer I;

[0048] (3) Mix cyclohexanol and deionized water at a mass ratio of 5:1, and use a shaker to mix at a speed of 200r / min for 0.5h to form solution A; mix polyethylene glycol and deionized water at a mass ratio of 1:6 , use a shaker to mix at a speed of 180r / min for 45min to form solution B; soak nickel nanowires with an average wire diameter of 100nm, an average wire length of 25μm, and an aspect ratio of 250...

Embodiment 3

[0051] Preparation of an Absorbent Flexible Transparent Electromagnetic Shielding Film

[0052] (1) After the ceramic substrate is ultrasonically cleaned with a cleaning agent, it is alternately rinsed 4 times with deionized water and absolute ethanol, then dried with high-purity nitrogen, and set aside;

[0053] (2) Print Ecoflex dimples with a viscosity of 50 mPa.s onto the ceramic substrate treated in step (1) and solidify at 60° C. for 30 minutes to obtain a flexible transparent polymer film layer I with a thickness of 80 μm;

[0054] (3) Mix hydroxyethyl cellulose and deionized water at a mass ratio of 1.5:1, and use a shaker to mix at a speed of 150r / min for 45 minutes to form solution A; mix sodium sulfamate and deionized water at a mass ratio of 1 : 8 mixed, utilizing a shaker to form solution B after mixing with a speed of 100r / min for 30min; the average wire diameter is 160nm, the average wire length is 32 μm, and the aspect ratio is 200 cobalt nanowires with a conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com