Preparation method of explosion-proof bulletproof thermal-insulation high-strength special coating

A high-strength, special technology, applied in the field of patents, can solve the problems of uneven dispersion, lack of flexibility, and lack of close bonding of high-molecular polymers, and achieve the effect of improving tensile properties, excellent physical properties, and good thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

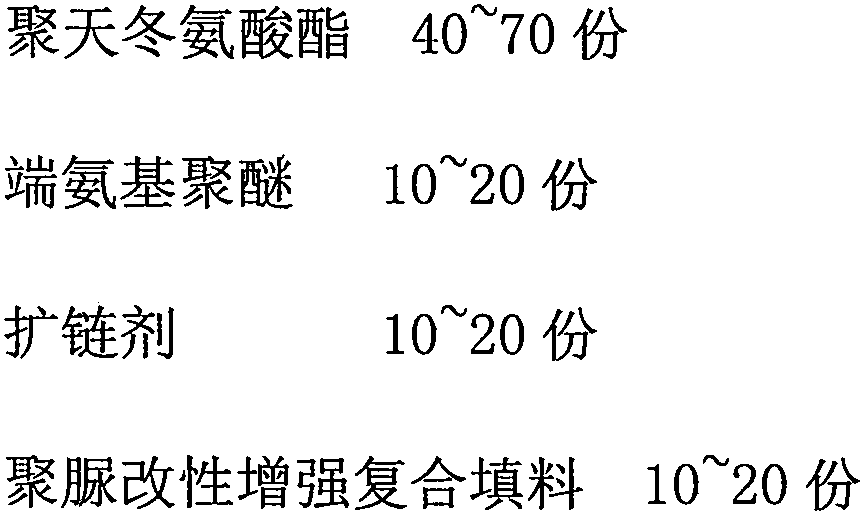

[0056] A component

[0057] Hexamethylene diisocyanate HDI 40% (Bayer, Germany)

[0058] huntsman N3390 60% (huntsman)

[0059] The above two components are mixed in proportion and recorded as "mixed isocyanate"

[0060] Mixed isocyanates 55%

[0061] Polytetrahydrofuran polyol PTMG1000 30% (Mitsubishi Japan)

[0062] Aminated carbon nanotube composite 15% (self-made)

[0063] To prepare component A:

[0064] After the above dehydration, mix evenly in the reactor, heat up to 80 degrees, stir, and react for 4 hours.

[0065] After filtering, it can be filled into barrels to obtain component A.

[0066] B component

[0067]

[0068] To prepare Component B:

[0069] After the dehydration of other components except the polyurea modified reinforced composite material, mix them in the reactor, raise the temperature to 80 degrees, and react for 3 hours.

[0070] Filter and barrel to get component B.

Embodiment 2

[0072] A component

[0073] Hexamethylene diisocyanate HDI 40% (Bayer, Germany)

[0074] huntsman N3390 60% (huntsman)

[0075] The above two components are mixed in proportion and recorded as "mixed isocyanate"

[0076] Mixed isocyanates 55%

[0077] Polytetrahydrofuran polyol PTMG1000 40% (Mitsubishi Japan)

[0078] Aminated carbon nanotube composite 5% (self-made)

[0079] To prepare component A:

[0080] After the above dehydration, mix evenly in the reactor, heat up to 85 degrees, stir, and react for 3 hours.

[0081] After filtering, it can be filled into barrels to obtain component A.

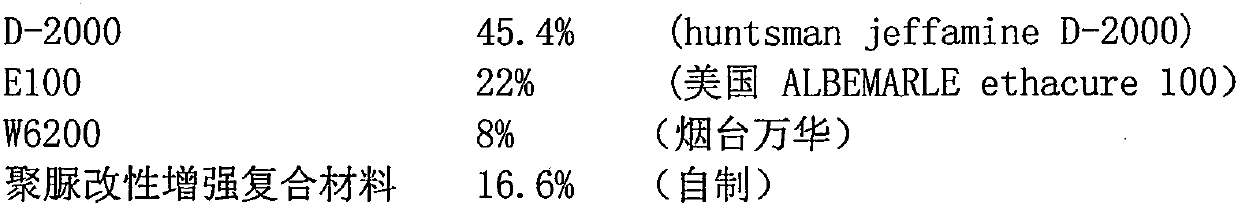

[0082] B component

[0083]

[0084] To prepare Component B:

[0085] After the dehydration of other components except the polyurea modified reinforced composite material, mix them in the reactor, raise the temperature to 85 degrees, and react for 2 hours.

[0086] Filter and barrel to get component B.

Embodiment 3

[0088] A component

[0089] Hexamethylene diisocyanate HDI 70% (Bayer, Germany)

[0090] IPDI 30% (Bayer, Germany)

[0091] The above two components are mixed in proportion and recorded as "mixed isocyanate"

[0092] Mixed isocyanates 55%

[0093] Polytetrahydrofuran polyol PTMG1000 30% (Mitsubishi Japan)

[0094] Aminated carbon nanotube composite 15% (self-made)

[0095] To prepare component A:

[0096] After the above dehydration, mix evenly in the reactor, heat up to 85 degrees, stir, and react for 3 hours.

[0097] After filtering, it can be filled into barrels to obtain component A.

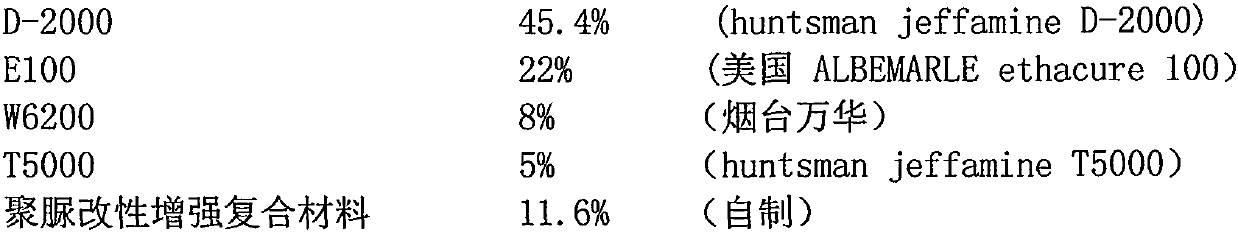

[0098] B component

[0099]

[0100] To prepare Component B:

[0101] After the dehydration of other components except the polyurea modified reinforced composite material, mix them in the reactor, raise the temperature to 85 degrees, and react for 2 hours.

[0102] Filter and barrel to get component B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com