Phosphorus-doped alumina-loaded palladium catalyst and preparation method thereof

An alumina-supported, palladium catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as low combustion activity, achieve less time-consuming, excellent performance, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

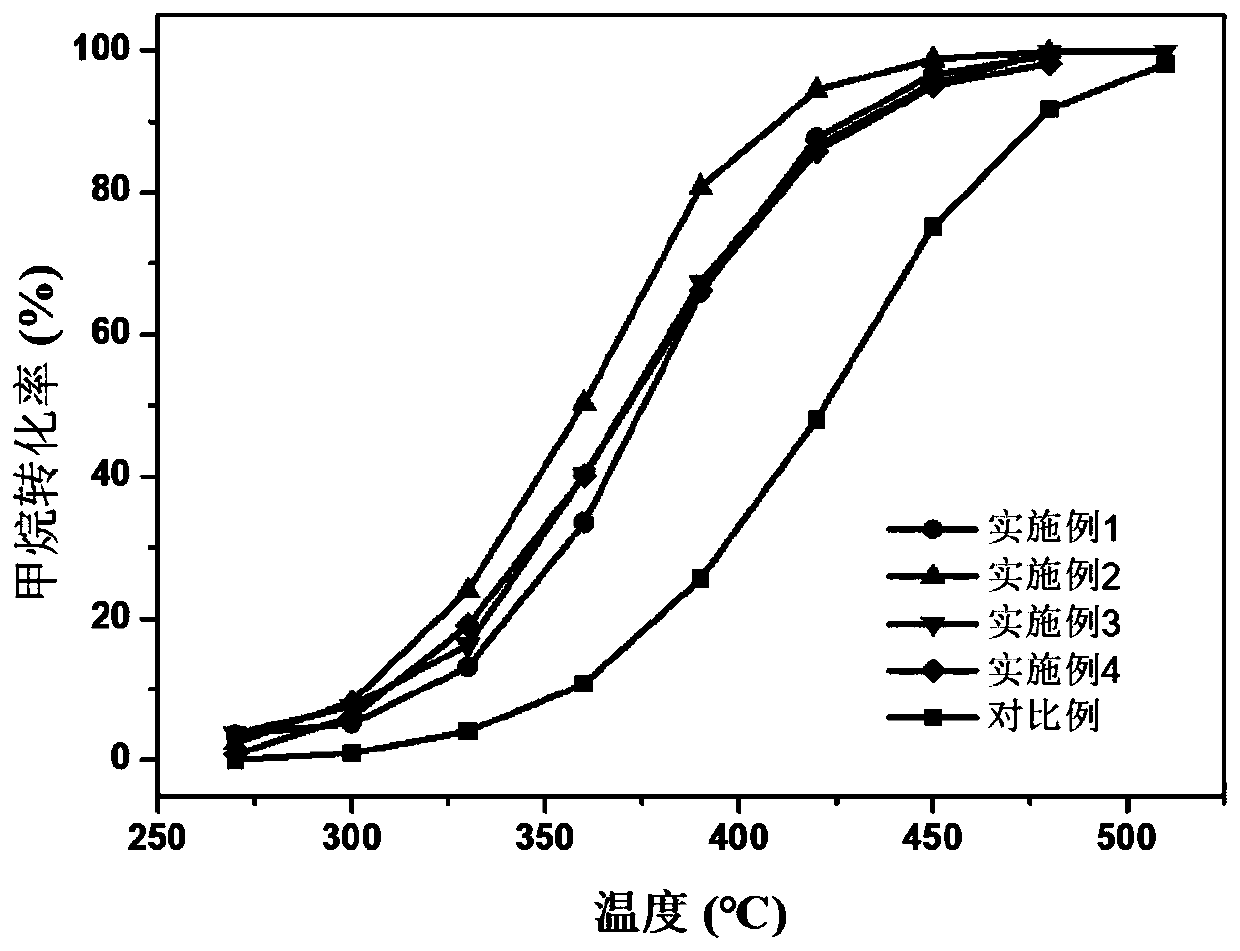

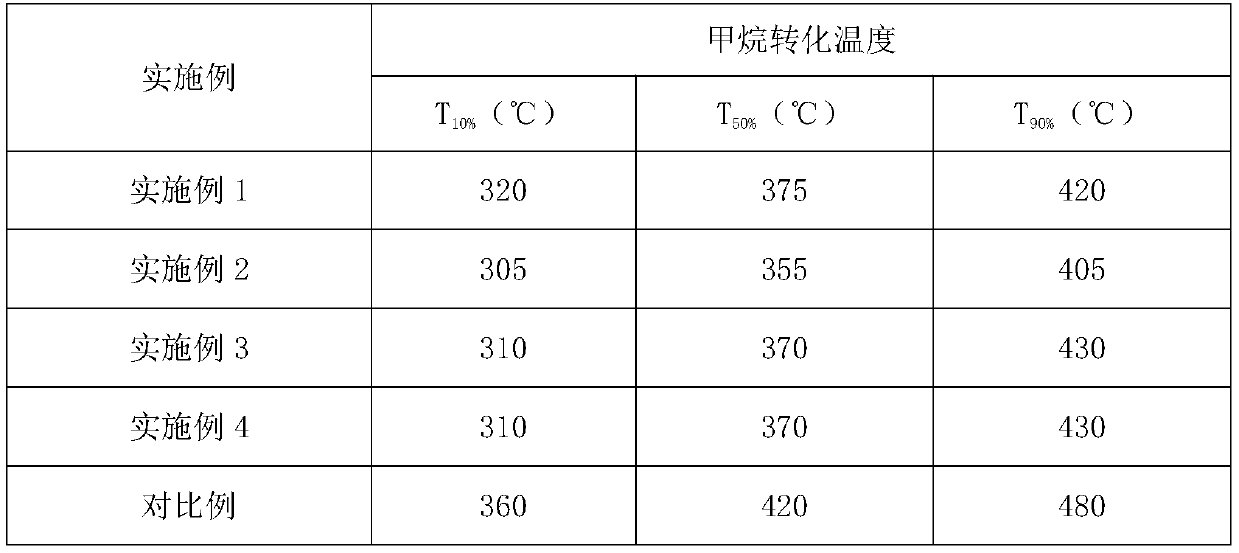

Embodiment 1

[0023] Add 20mL absolute ethanol to 1gP123, stir and dissolve, then add 3mLH 2 O, 2.04g of ammonia water, 0.0084g of ammonium hypophosphite and mix well; dissolve 3.75g of aluminum nitrate nonahydrate in 10mL of absolute ethanol and add dropwise to the above mixed solution; after stirring at room temperature for 3h, place it in a constant temperature water bath at 80°C and stir for 0.5h , placed in an oven at 80°C for 12 hours, placed in a muffle furnace, heated at a rate of 2°C / min to 500°C for 4 hours, and then heated at a rate of 5°C / min to 900°C for 4 hours to obtain the target carrier, 1mol% P-Al 2 o 3 -900;

[0024] 1g 1mol% P-Al 2 o 3 Add 0.64mL dichlorotetraammine palladium solution (7.84mg / mL) to the -900 carrier to make an impregnation solution with pH = 12, immerse at 20-30°C for 12h, put it in an oven at 110°C for 12h, and then Put it in a muffle furnace, raise the temperature at a rate of 5°C / min to 500°C and roast for 4h to obtain 0.5wt%Pd / 1mol%P-Al 2 o 3 ...

Embodiment 2

[0027] Add 20mL absolute ethanol to 1gP123, stir and dissolve, then add 3mLH 2 O, 2.04g of ammonia water, 0.0256g of ammonium hypophosphite, and mix well; dissolve 3.75g of aluminum nitrate nonahydrate in 10mL of absolute ethanol and add dropwise to the above mixed solution; after stirring at room temperature for 3h, place it in a constant temperature water bath at 80°C and stir for 0.5h , placed in an oven at 80°C for 12 hours, placed in a muffle furnace, heated at a rate of 2°C / min to 500°C for 4 hours, and then heated at a rate of 5°C / min to 900°C for 4 hours to obtain the target carrier 3mol%P -Al 2 o 3 -900;

[0028] 1g 3mol% P-Al 2 o 3 Add 0.64mL dichlorotetraammine palladium solution (7.84mg / mL) to the -900 carrier to make an impregnation solution with pH = 12, immerse at 20-30°C for 12h, put it in an oven at 110°C for 12h, and then Put it in a muffle furnace, raise the temperature at a rate of 5°C / min to 500°C and roast for 4 hours to obtain 0.5wt%Pd / 3mol%P-Al 2 ...

Embodiment 3

[0031] Add 20mL absolute ethanol to 1gP123, stir and dissolve, then add 3mLH 2 O, 2.04g of ammonia water, 0.0426g of ammonium hypophosphite, and mix well; dissolve 3.75g of aluminum nitrate nonahydrate in 10mL of absolute ethanol and add dropwise to the above mixed solution; after stirring at room temperature for 3h, place it in a constant temperature water bath at 80°C and stir for 0.5h , placed in an oven at 80°C for 12 hours, placed in a muffle furnace, heated at a rate of 2°C / min to 500°C for 4 hours, and then heated at a rate of 5°C / min to 900°C for 4 hours to obtain the target carrier 5mol%P -Al 2 o 3 -900;

[0032] 1g 5mol% P-Al 2 o 3 Add 0.64mL dichlorotetraammine palladium solution (7.84mg / mL) to the -900 carrier to make an impregnation solution with pH = 12, immerse at 20-30°C for 12h, put it in an oven at 110°C for 12h, and then Put it in a muffle furnace, raise the temperature at a rate of 5°C / min to 500°C and roast for 4 hours to obtain 0.5wt%Pd / 5mol%P-Al 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com