Method for disinfecting water body based on multi-component composite material visible light catalysis

A composite material and visible light technology, which is applied in chemical instruments and methods, disinfectants, special compound water treatment, etc., can solve the problems of sterilizing efficiency to be strengthened, consumption, etc., to achieve water purification effect, high conductivity, and reduce agglomeration The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

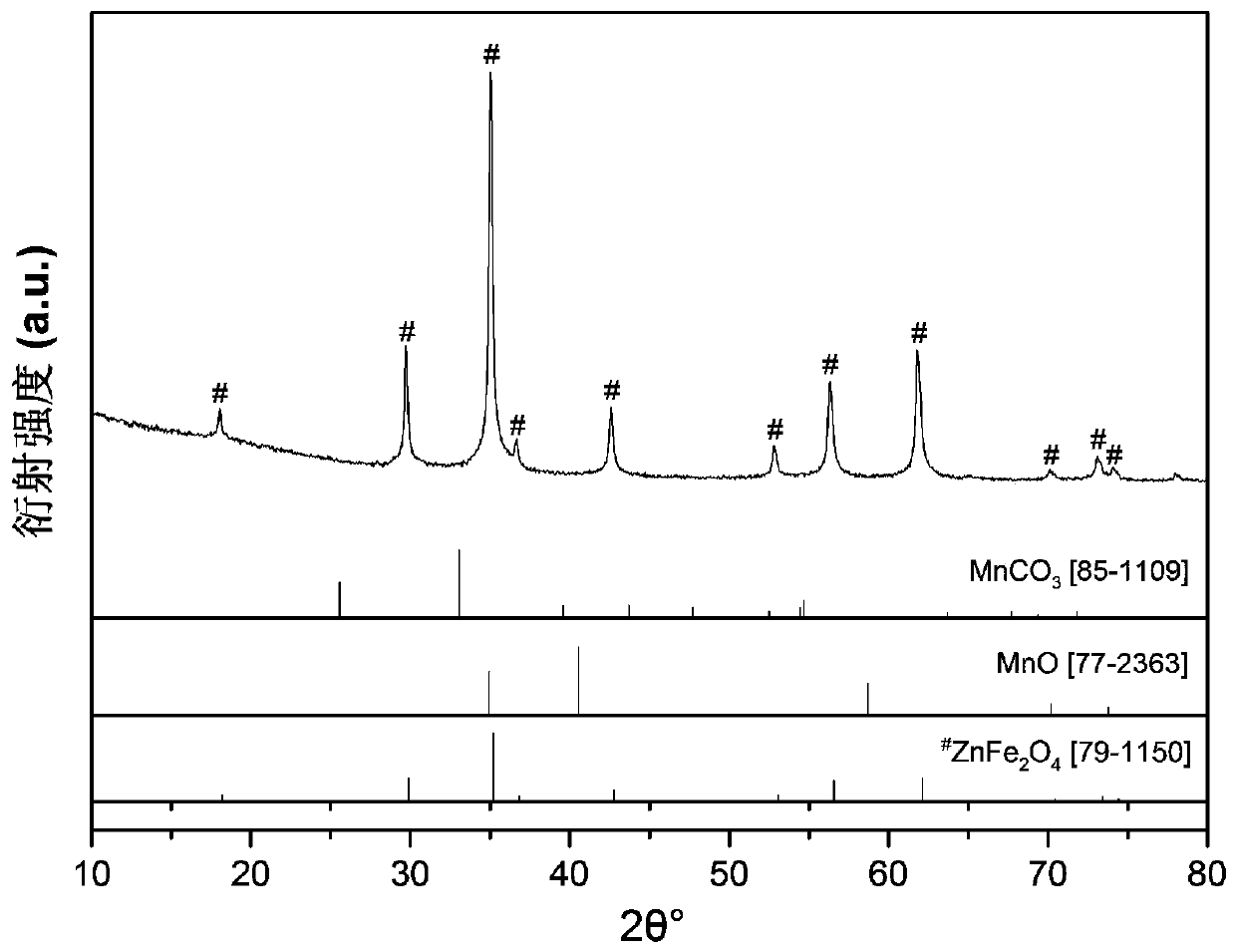

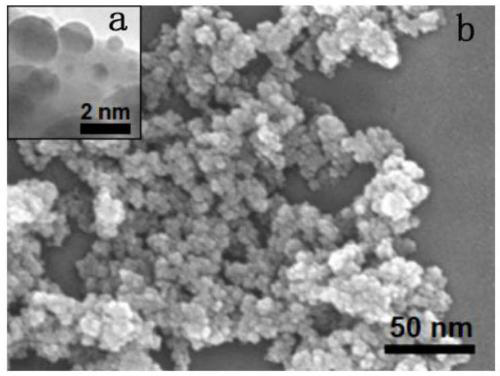

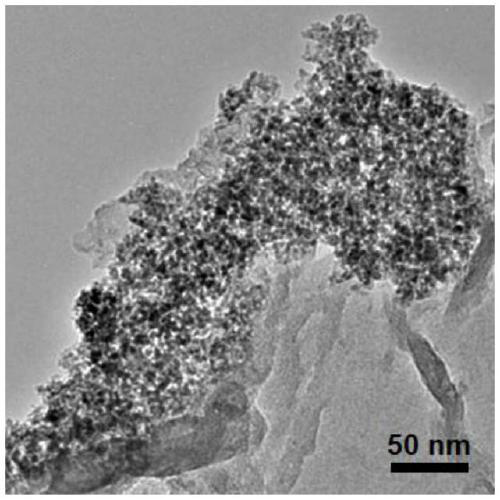

[0032] Example 1 Zinc-manganese ferrite / nano-silver / graphene multi-component composite material efficiently inactivates Escherichia coli under visible light irradiation, the steps are as follows:

[0033] 1) Dissolve 1.26g of citric acid in 10mL of deionized water to prepare a citric acid solution. 0.3g Zn(NO 3 ) 2 ·6H 2 O, 0.25g Mn(NO 3 ) 2 4H 2 O and 1.6g Fe(NO 3 ) 3 9H 2 O was dissolved in 20 mL of deionized water, mixed with the above-prepared citric acid solution, stirred, and sonicated, then transferred to a water bath at 65 °C and stirred at a low speed for 15 minutes to form a uniform citric acid complex, namely Zn / Mn / Fe -Citrate complex (citric acid is used as a complexing agent, the main purpose here is to improve the steric effect between metal ions and obtain small-scale nanomaterials);

[0034] 2) Dissolve 1.36g NaOH in 10mL water to prepare NaOH solution. Under vigorous stirring, the NaOH solution prepared above was slowly added dropwise to the mixed so...

Embodiment 2

[0057] Example 2 Zinc-manganese ferrite / nano-silver / graphene multi-component composite material efficiently inactivates Pseudomonas aeruginosa under visible light irradiation, the steps are as follows:

[0058] In this example, the preparation process of zinc-manganese ferrite / nano-silver / graphene multi-component composite material was repeated in Example 1.

[0059] The multi-component composite material prepared in Example 2 is applied to water body disinfection and sterilization, and the process is as follows:

[0060] S1: Prepare 50 mL of pre-cultured Pseudomonas aeruginosa in pH 7.4 phosphate buffer solution, control the logarithmic value of the colony at about 7, add 5 mg of the zinc-manganese ferrite / nano-silver / graphene multi-component composite material prepared in Example 2 ;

[0061] S2: Under magnetic stirring, turn on the LED light and add 8.5 microliters of 30% H 2 o 2 Solution, stimulate the visible light photo-Fenton catalytic reaction;

[0062] S3: After 3...

Embodiment 3

[0064] Example 3 Zinc-manganese ferrite / nano-silver / graphene multi-component composite material efficiently inactivates Staphylococcus aureus under visible light irradiation, the steps are as follows:

[0065] In this example, the preparation process of zinc-manganese ferrite / nano-silver / graphene multi-component composite material was repeated in Example 1.

[0066] The multi-component composite material prepared in Example 3 is applied to disinfection and sterilization of water bodies, and the process is as follows:

[0067] S1: Prepare 50 mL of pre-cultivated Staphylococcus aureus in pH 7.4 phosphate buffer, control the logarithm of the colony to be around 7, add 5 mg of the zinc-manganese ferrite / nano-silver / graphene multi-component composite material prepared in Example 3;

[0068] S2: Under magnetic stirring, turn on the LED light and add 8.5 microliters of 30% H 2 o 2 Solution, stimulate the visible light photo-Fenton catalytic reaction;

[0069] S3: After 30 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com