Silver nanowire antibacterial layer and silver nanowire mask

A technology of nano-silver wire and anti-bacterial layer, applied in coatings, clothing, protective clothing, etc., can solve the problems of limiting the anti-bacterial and anti-virus capabilities of nano-silver masks, poor adhesion, etc., and achieve high hydrophobicity, high safety, and comfortable wearing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A nano silver wire antibacterial layer, its preparation method comprises the steps:

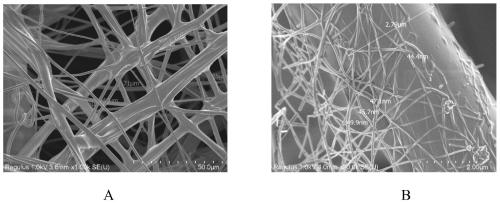

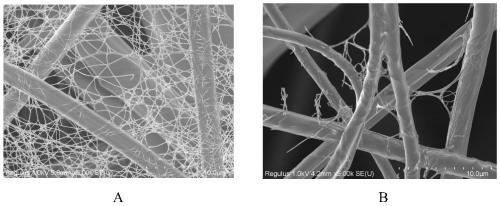

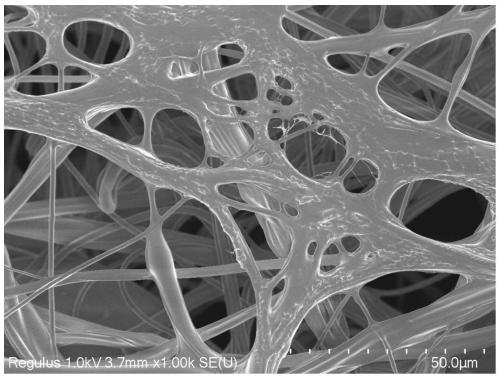

[0031] (1) Mixing silver nanowires with a diameter of 8-12nm and a length of 30-40 μm and an organic silicon modifier in ethylene glycol to obtain a reaction stock solution, the mass fraction of the silver nanowires in the reaction stock solution is 0.01%, so The organosilicon modifier mass fraction is 1%, reacted for 2 hours at 120°C and 300r / min mechanical stirring to obtain a reaction solution, cleaned with acetone and blown with nitrogen to obtain a modified nano-silver wire with a low-thickness protective layer. Wire;

[0032] (2) Adding the modified silver nanowires into a mixture of water: ethanol: isopropanol = 1:5:4 by mass percentage to obtain a suspension of silver nanowires with a mass fraction of 0.01%;

[0033] (3) Spray the nano-silver wire suspension evenly on a polytetrafluoroethylene film (PTFE film) with a pore size of 300 nm with an air spray gun, and sinter at a l...

Embodiment 2

[0035] A nano silver wire antibacterial layer, its preparation method comprises the steps:

[0036] (1) Mixing silver nanowires with a diameter of 8-12nm and a length of 30-40 μm and an organic silicon modifier in ethylene glycol to obtain a reaction stock solution, the mass fraction of the silver nanowires in the reaction stock solution is 0.01%, so The mass fraction of the organic silicon modifier is 2%, reacted at 120° C. and 300 r / min under mechanical stirring for 2 hours to obtain a reaction solution, cleaned with acetone and blown with nitrogen to obtain a modified nano-silver wire with a low-thickness protective layer. Wire;;

[0037] (2) Adding the modified silver nanowires into a mixture of water: ethanol: isopropanol = 1:4:4 by mass percentage to obtain a suspension of silver nanowires with a mass fraction of 0.005%;

[0038] (3) Spray the nano-silver wire suspension evenly on a PTFE film with a pore size of 200 nm with an air spray gun, and sinter at a low temperat...

Embodiment 3

[0040] A nano silver wire antibacterial layer, its preparation method comprises the steps:

[0041] (1) Mixing silver nanowires with a diameter of 8-12nm and a length of 30-40 μm and an organic silicon modifier in ethylene glycol to obtain a reaction stock solution, the mass fraction of the silver nanowires in the reaction stock solution is 0.01%, so The mass fraction of the organic silicon modifier is 1%, reacted at 100° C. and 300 r / min under mechanical stirring for 2 hours to obtain a reaction solution, cleaned with acetone and blown with nitrogen to obtain a modified nano-silver wire with a low-thickness protective layer. Wire;

[0042] (2) Adding a mass percentage of water: ethanol: isopropanol = 1:5:4 to the modified silver nanowires to obtain a suspension of silver nanowires with a mass fraction of 0.1%;

[0043] (3) Spray the nano-silver wire suspension evenly on a PTFE film with a pore size of 200 nm with an air spray gun, and sinter at a low temperature of 85° C. to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com