Method for converting titanium components in titanium-bearing blast furnace slag into ilmenite

A technology of blast furnace slag and ilmenite, which is applied in the field of converting titanium components into ilmenite in titanium-containing blast furnace slag, can solve the problems of complex process, high recovery cost, and high content, and achieve simple process flow and high-efficiency utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

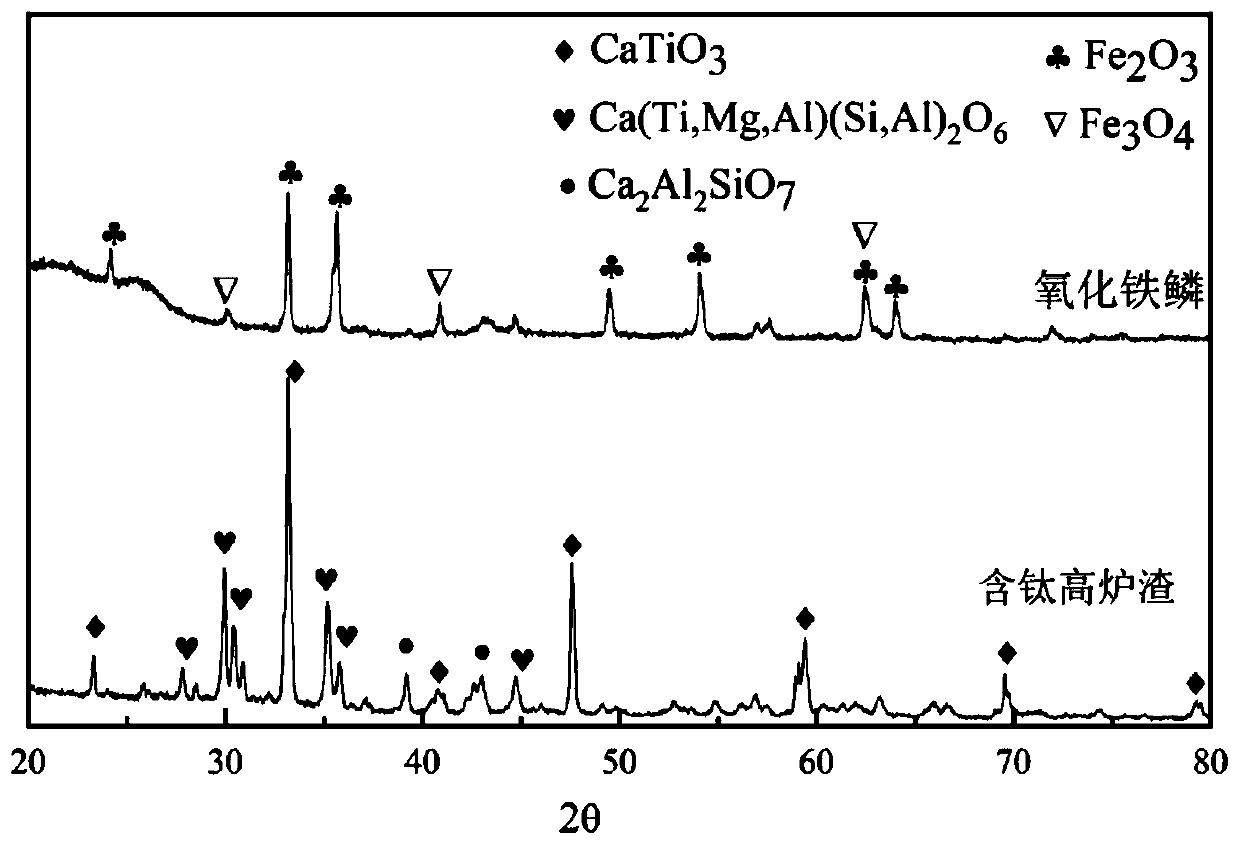

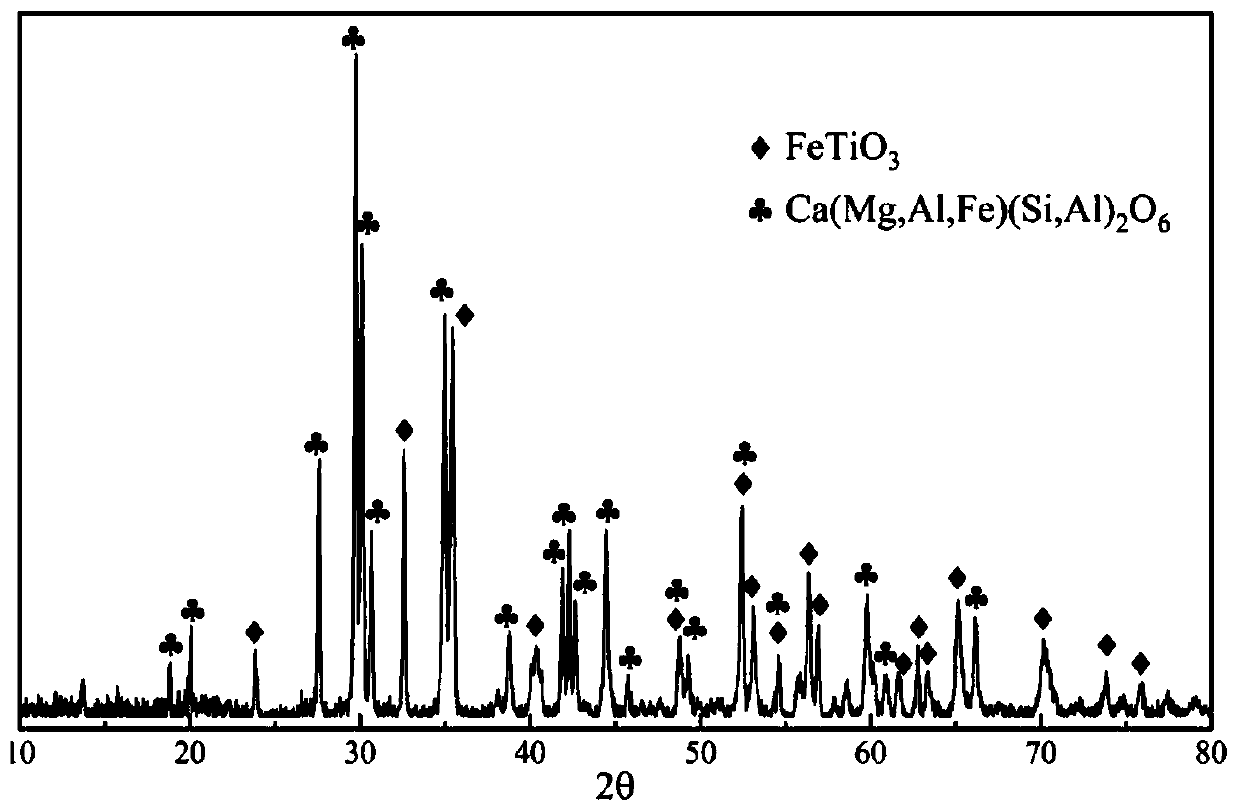

[0022] The titanium-containing blast furnace slag and iron oxide scale are dried and pulverized, and the coke block is pulverized and sieved to obtain powders of 100-300 mesh respectively. Mix the obtained titanium-containing blast furnace slag, iron oxide scale, coke powder and silicon dioxide in a mass ratio of 10:4.0:0.45:2.5, and press it into a disc under a pressure of 1Mpa. The diameter of the obtained tablet is 5mm , the thickness is 2mm. Put the obtained tablet into an alumina crucible, then put the alumina crucible into a high-temperature furnace, first pass argon gas for 30 minutes to drive away the air in the furnace cavity, then start heating up, and react at a temperature of 1375°C for 240 minutes. After the reaction was completed, it was cooled to 1000°C with the furnace. During the process, the argon gas protection was always passed, and then the alumina crucible was taken out and cooled to room temperature naturally. The titanium-containing component in the obt...

Embodiment 2

[0024] Dry and pulverize the titanium-containing blast furnace slag and iron oxide scale, and pulverize the coke blocks, and then sieve them to obtain powders of 100-200 mesh respectively. Mix the obtained titanium-containing blast furnace slag, iron oxide scale, coke powder and silicon dioxide in a mass ratio of 10:3.5:0.4:2, and press it into a disc under a pressure of 5 MPa. The diameter of the obtained tablet is 10mm , the thickness is 4mm. Put the obtained tablet into an alumina crucible, then put the alumina crucible into a high-temperature furnace, first pass argon gas for 30 minutes to drive away the air in the furnace cavity, then start heating up, react at 1300°C for 420 minutes, and heat up And the reaction process is protected by argon, and the furnace is cooled to 1000 ° C. After the reaction, the alumina crucible is taken out and cooled to room temperature naturally. The titanium-containing component in the obtained synthetic slag has been converted into ilmenite...

Embodiment 3

[0026] The titanium-containing blast furnace slag and iron oxide scale are dried and pulverized, and the coke block is pulverized and sieved to obtain powders of 200-300 mesh respectively. Mix the obtained titanium-containing blast furnace slag, iron oxide scale, coke powder and silicon dioxide in a mass ratio of 10:3.0:0.3:1.5, and press it into a disc under a pressure of 1Mpa. The diameter of the obtained tablet is 5mm , the thickness is 2mm. Put the obtained pellets into an alumina crucible, then put the alumina crucible into a high-temperature furnace, first pass argon gas for 30 minutes to drive away the air in the furnace cavity, then start heating up, and react at a temperature of 1450°C for 240 minutes , after the reaction was completed, it was cooled to 1000°C with the furnace, and the argon gas was kept flowing during the process, and then the alumina crucible was taken out and cooled to room temperature naturally. Figure with figure 2 almost the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com