Forming equipment for producing dried rolled bean curd under normal-pressure steam conditions

A technology of atmospheric steam and molding equipment, which is used in steam generation, steam superheating, steam boilers, etc., can solve problems such as deformation, insufficient combustion of tunnel fire channel fuel, and affecting the output and quality of yuba

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

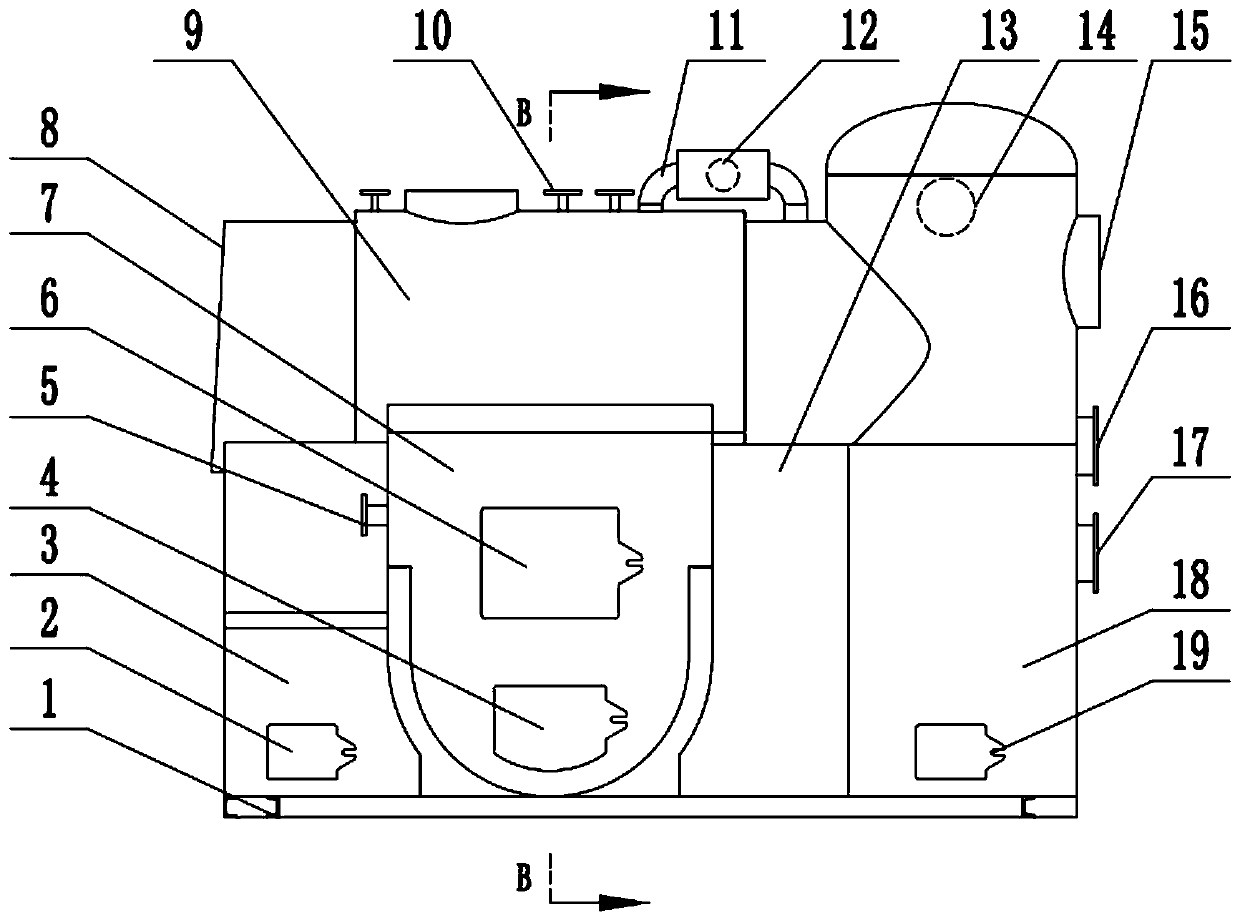

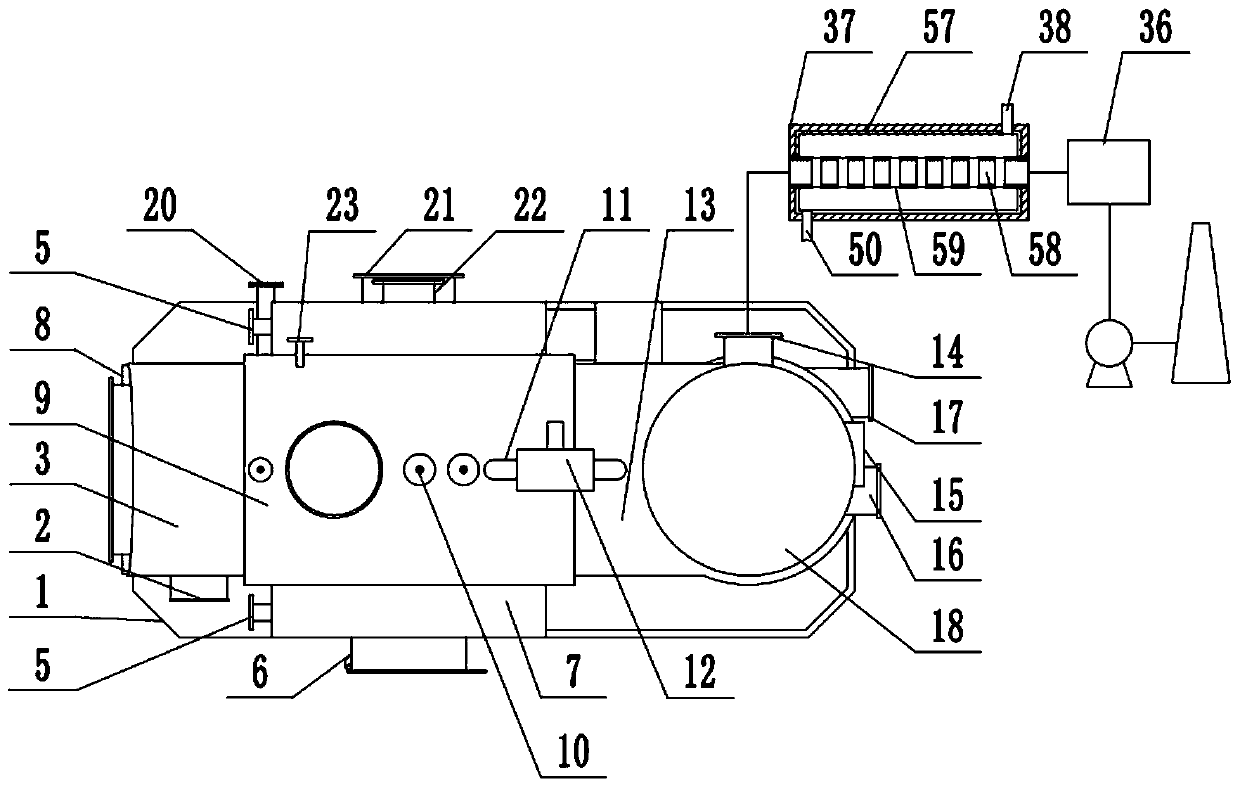

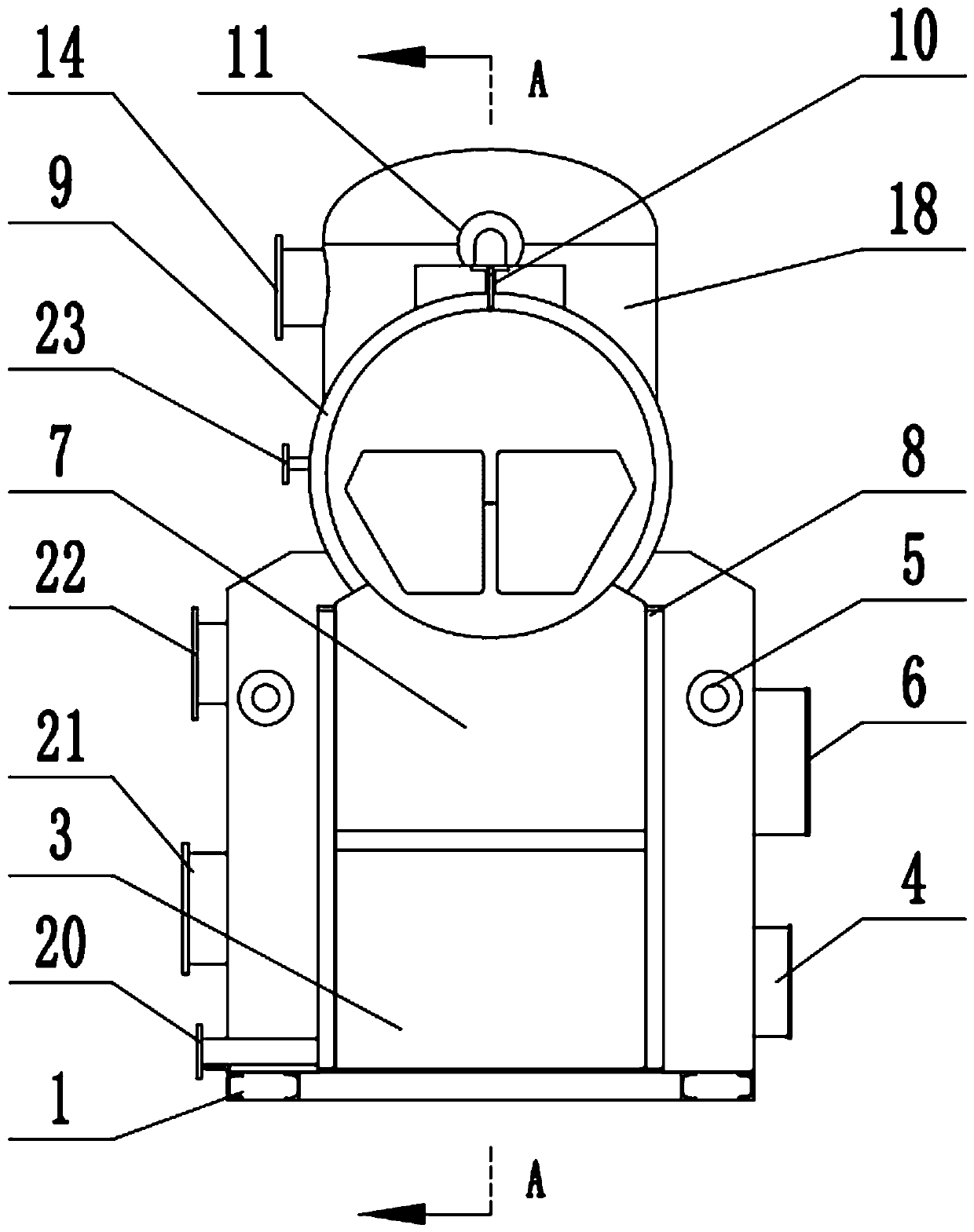

[0062] A bean curd stick production and molding equipment under normal pressure steam conditions, comprising a counter-burning atmospheric pressure superheated steam furnace and a bean curd stick forming device, and the counter-burning normal pressure superheated steam furnace provides steam for the bean curd stick forming device for heating and forming;

[0063] Described bean curd stick molding device comprises a slurry tank 46 and a support 51, and the slurry tank 46 is a rectangular shape with an upper opening, and a plurality of dividing plates 52 are installed in it by a draw-in groove 53, and the dividing plates 52 will fill the slurry tank 46 is divided into a plurality of forming pools, and the forming pools are arranged in two rows; the slurry tank 46 is installed on the support 51; the bottom of the slurry tank 46 is provided with a steam chamber 45, and a steam inlet pipe 43 is installed in the steam chamber 45. The steam pipe 43 stretches into the middle part of th...

Embodiment 2

[0066] A bean curd stick production and molding equipment under normal pressure steam conditions, comprising a counter-burning atmospheric pressure superheated steam furnace and a bean curd stick forming device, and the counter-burning normal pressure superheated steam furnace provides steam for the bean curd stick forming device for heating and forming;

[0067] Described bean curd stick molding device comprises a slurry tank 46 and a support 51, and the slurry tank 46 is a rectangular shape with an upper opening, and a plurality of dividing plates 52 are installed in it by a draw-in groove 53, and the dividing plates 52 will fill the slurry tank 46 is divided into a plurality of forming pools, and the forming pools are arranged in two rows; the slurry tank 46 is installed on the support 51; the bottom of the slurry tank 46 is provided with a steam chamber 45, and a steam inlet pipe 43 is installed in the steam chamber 45. The steam pipe 43 stretches into the middle part of th...

Embodiment 3

[0075] A bean curd stick production and molding equipment under normal pressure steam conditions, comprising a counter-burning atmospheric pressure superheated steam furnace and a bean curd stick forming device, and the counter-burning normal pressure superheated steam furnace provides steam for the bean curd stick forming device for heating and forming;

[0076] Described bean curd stick molding device comprises a slurry tank 46 and a support 51, and the slurry tank 46 is a rectangular shape with an upper opening, and a plurality of dividing plates 52 are installed in it by a draw-in groove 53, and the dividing plates 52 will fill the slurry tank 46 is divided into multiple forming pools, and the forming pools are arranged in two rows; the slurry tank 46 is installed on the support 51; the bottom of the slurry tank 46 is provided with a steam chamber 45;

[0077] Two steam inlet pipes 43 are installed in the steam chamber 45, and the two steam inlet pipes 43 all extend from on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com