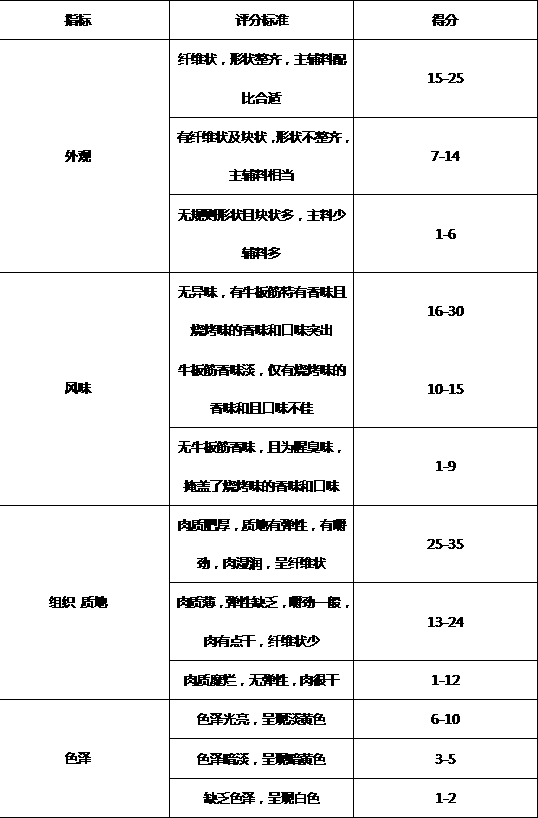

Technology for producing instant translucent bull paddywack with barbecue flavor

A production process, beef tendon technology, applied in food ingredients as taste improver, food science and other directions, can solve problems such as affecting consumers' shopping experience, reducing product sales, unfavorable mass production, etc., to improve product aesthetics, The effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Get 1000 grams of frozen beef ribs, let the tap water stand to thaw, remove ice and impurities, add a compound protease to treat for 2.0 hours, the compound enzyme is composed of flavor protease, papain and subtilisin, and the weight ratio is 1:3:1, The dosage of the compound protease is 0.05% of the weight of beef tendons after thawing. Then immediately boil in water above 90°C for 3 minutes, take out the water and remove the oil, check whether the butter adhesion film and butter on the beef ribs are completely removed, cut into sections with a cutting machine, and then draw them with a wire drawing machine, and then cut them into pieces The oil-removed beef ribs add barbecue-flavored ingredients (the weight ratio of Dengying beef ribs to ingredients is 1:1), and the ingredients consist of edible salt, monosodium glutamate, white sugar, sesame, spices, chili sauce, cumin oil, and compound seasonings , other additives, etc., the weight ratio is 1:0.75:1.25:10:0.5:6:1.25...

Embodiment 2

[0023] Get 1000 grams of frozen beef ribs, let the tap water stand to thaw, remove ice and impurities, add a compound protease for 1.5 hours, and the compound enzyme is composed of flavor protease, papain and subtilisin, and the weight ratio is 1:3:1. The dosage of compound protease is 0.01% of the weight of beef tendon after thawing. Then immediately boil it in water above 90°C for 1 minute, take out the water and remove the oil, check whether the butter adhesion film and butter of the beef ribs are completely removed, cut into sections with a cutting machine and then draw them with a wire drawing machine, and then pull them out The oil-removed Dengying beef ribs add barbecue flavor ingredients (the weight ratio of beef ribs to ingredients is 1:1), and the ingredients consist of edible salt, monosodium glutamate, white sugar, sesame, spices, chili sauce, cumin oil, compound Condiments, other additives, etc., the weight ratio is 1:0.75:1.25:10:0.5:6:1.25:14.85:0.25, the ingred...

Embodiment 3

[0025] Get 1000 grams of frozen beef gluten, let it stand for thawing in tap water, remove ice and impurities, add compound protease to treat for 3.0 hours, and the compound enzyme is composed of flavor protease, papain and subtilisin, and the weight ratio is 1:3:1, The dosage of compound protease is 0.1% of the weight of beef tendon after thawing. Then immediately boil in water above 90°C for 5 minutes, take out the water and remove the oil, check whether the butter adhesion film and butter of the beef ribs are completely removed, cut into sections with a cutting machine, and then draw them with a wire drawing machine, and then draw them The oil-removed Dengying beef ribs add barbecue flavor ingredients (the weight ratio of beef ribs to ingredients is 1:1), and the ingredients consist of edible salt, monosodium glutamate, white sugar, sesame, spices, chili sauce, cumin oil, compound Condiments, other additives, etc., the weight ratio is 1:0.75:1.25:10:0.5:6:1.25:14.85:0.25, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com