A kind of drug coating and preparation method thereof

A drug coating and drug technology, applied in the field of medical devices, can solve the problems of drug coating phase separation, low bioavailability, drug coating loss, etc., to reduce shedding and loss, promote cell aggregation and growth, Promotes the repair of damaged mucosa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

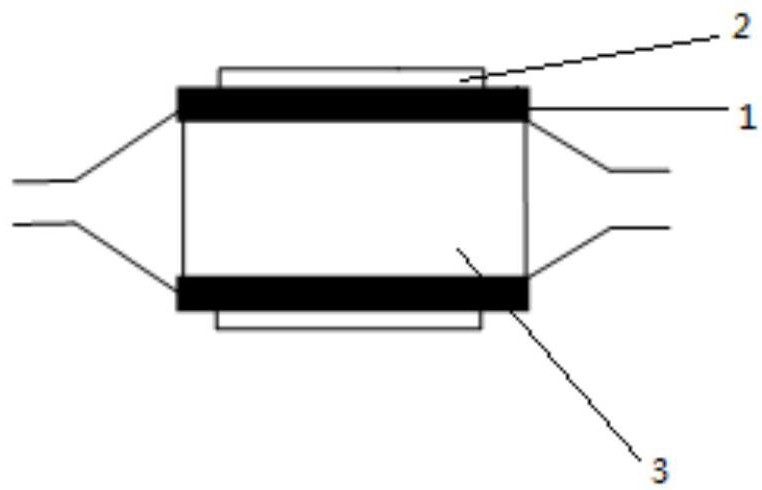

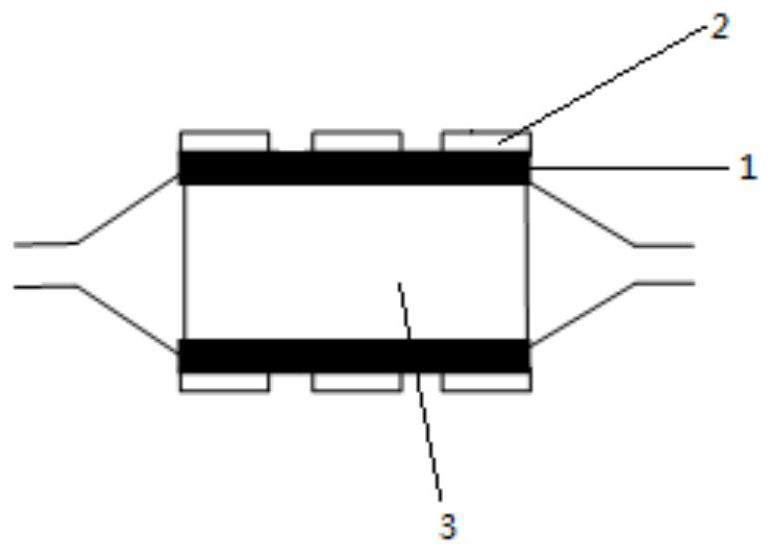

Image

Examples

preparation example Construction

[0074] The embodiment of the present invention also discloses a preparation method of a drug coating, comprising the following steps:

[0075] (A) dissolving a biodegradable polymer with an amino group or a protonated amino group in a first solvent to obtain a first solution, and coating the first solution on the surface of the medical device to form a bottom layer;

[0076] (B) Coating a solution containing drugs, non-ionic water-soluble compounds and degradable polymers with carboxyl or carboxylate groups on part of the surface of the bottom layer to form a surface layer.

[0077] According to the present invention, step (A) dissolves the biodegradable polymer with amino group or protonated amino group in the first solvent to obtain the first solution, and coats the first solution on the surface of the medical device to form the bottom layer .

[0078] The first solvent is preferably one or more of acetone, tetrahydrofuran, methanol, ethanol, isopropanol, N,N-dimethylacetam...

Embodiment 1

[0124] a, bottom layer solution preparation: 0.5g chitosan quaternary ammonium salt (Mn=250000D), dissolve in 15mL deionized water, then magnetically stir at 50°C for 60 minutes until fully dissolved, add 5mL methanol to the deionized aqueous solution to prepare a mixture The solution was left to stand for 24 hours before use.

[0125] b. Preparation of surface layer solution: the first component, 0.5g of sodium hyaluronate (Mn=45000D), was dissolved in 10ml of deionized water, magnetically stirred at room temperature for 60 minutes until completely dissolved, and 10mL of ethanol was added to the deionized aqueous solution to prepare a mixed solution Stand still for 24 hours for use; the mixture of the second component 0.0875g glycerin and the third component 0.25g paclitaxel (purity > 95%) was dissolved in 10mL ethanol solution, magnetically stirred at room temperature for 30 minutes until completely dissolved, and added to ethanol Add 10mL deionized water to the solution to ...

Embodiment 2

[0128] a, bottom solution preparation: 0.5g hydroxypropyl chitosan (Mn=300000D), be dissolved in 8mL deionized water, magnetically stir at normal temperature for 60 minutes to dissolve completely, add 2mL ethanol in deionized water and prepare to mix The solution was left to stand for 24 hours before use.

[0129] b. Preparation of degradable polymer mixed solution: first component 0.65g polylactic acid-glycolic acid copolymer (Mn=14000D), second component 0.1g rhamnosyl ester (content > 85%; monorhamnosyl ester Content > 50%), the third component 0.05 pyridine carboxamide mixture was dissolved in 30ml of tetrahydrofuran and deionized water mixed solution (tetrahydrofuran: deionized water = 2:1), 40 ℃ environment until completely dissolved and let stand for 24 hours stand-by;

[0130] c. Drug solution preparation: the first component 0.35g rapamycin (purity > 95%) and the second component 0.015g vitamin C mixture were dissolved in 10ml ethanol, magnetically stirred at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com