Preparation method of modified evaporation wall for supercritical water oxidation reactor

A supercritical water oxidation and evaporation wall technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc. Burning or corrosion problems, to achieve the effect of strong operability, enhanced stability, and maintenance of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention relates to a preparation method of a modified evaporation wall for a long-life and corrosion-resistant supercritical water oxidation reactor. The adhesion force of the evaporation wall to the droplet is tailored according to the actual working conditions to maintain the integrity of the water film, including The following steps:

[0037]According to the water film flow velocity on the inner surface of the evaporation wall corresponding to different actual working conditions, the idea of modifying the surface of the evaporation wall from the micro-nano scale is used to design the appropriate surface roughness of the evaporation wall.

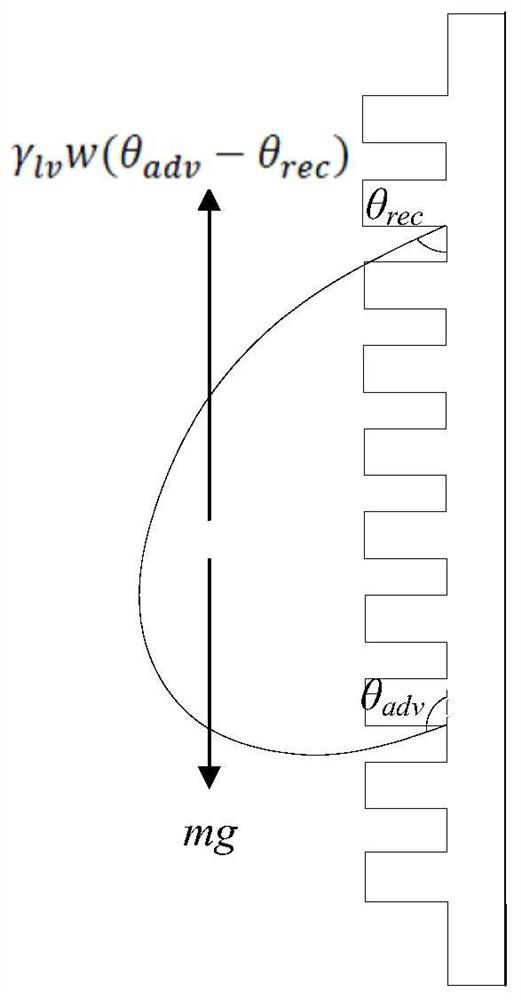

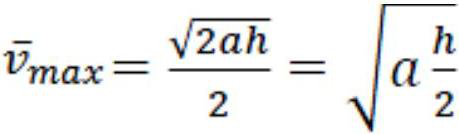

[0038] Step 1. According to the actual working conditions, the water film flow velocity is required Substituting formula I and formula II to calculate the corresponding adhesion force γ lv w(θ adv -θ rec ) to design a suitable surface roughness.

[0039] Step 2: Ultrasonic cleaning the metal porous plate in acetone for...

Embodiment 1

[0052] Embodiment 1 of the present invention relates to a preparation method of a modified evaporation wall for a supercritical water oxidation reactor applied to the treatment of printing and dyeing sludge, comprising the following steps:

[0053] Step 1. The supercritical water oxidation evaporation wall reactor treats printing and dyeing sludge. The reaction temperature and pressure are 560°C-600°C and 25-27MPa respectively. The water film absorbs the heat of the evaporation wall-C 钛 m 蒸发壁 (T 反应器 -T 额 )=C 水 m 水 (T 入 -T 额 ) to calculate the evaporation wall temperature down to the rated service temperature T of the evaporation wall 额 When , the amount of water required by the water film m 水 (where C 钛 and C 水 are the specific heat capacities of titanium-based evaporation wall and distilled water, m 蒸发壁 is the mass of the evaporation wall, T 反应器 is the reaction temperature inside the reactor, T 入 is the temperature when distilled water enters the reactor). Then a...

Embodiment 2

[0062] Embodiment 2 of the present invention relates to a preparation method of a modified evaporation wall for a supercritical water oxidation reactor applied to the treatment of TNT wastewater, comprising the following steps:

[0063] Step 1. The supercritical water oxidation evaporation wall reactor treats TNT waste water. The reaction temperature and pressure are 580°C-600°C and 24-25MPa respectively. Referring to step 1 of Example 1, the water required on the evaporation wall can be estimated Membrane Maximum Average Flow Velocity About 1.42m / s, substituted into the designed formula I and formula II to calculate the corresponding adhesion force γ lv w(θ adv -θ rec ) is 17μN (taking a 1.5L evaporation wall reactor as an example, the height h of the evaporation wall is about 45cm, and a drop of water weighs about 0.02g).

[0064] The content of organic matter in TNT wastewater is very high (10000mg / L), strong alkalinity, pH = 9-11, and high sulfur content, which will de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com