Copper foil in-situ growth three-dimensional copper sulfide negative electrode material for sodium-ion battery, preparation method and application

A technology for sodium ion batteries and negative electrode materials, which is applied in the manufacture of copper sulfide, battery electrodes, and secondary batteries. The effect of low cost and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

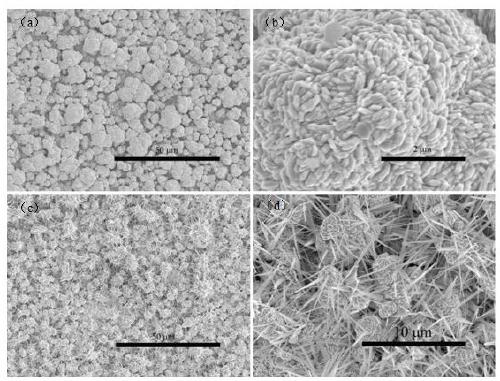

Image

Examples

Embodiment 1

[0024] (1) Cut the 0.01 mm copper foil into 3×4 cm, put it in absolute ethanol, acetone, and deionized water for 3 minutes, and soak it in 1.0 M hydrochloric acid for 1 minute to obtain some polished copper foils;

[0025] (2) Add 1.5 M Na 2 S 9H 2 O was dissolved in 200 ml deionized water to obtain solution A;

[0026] (3) Adjust the three-constant reaction instrument, with a constant current output of 10 mA, graphite sheet as the cathode, high-purity copper foil as the anode, solution A as the electrolyte, react for 10 min, and rinse the copper foil after the reaction with deionized water repeatedly And blow dry with nitrogen, obtain the product A that copper foil is attached with black active material;

[0027] (4) The product A was placed in argon at 200 °C, annealed for 1 h to 200 °C and kept for 2 h to obtain product B with copper sulfide attached.

[0028] The battery copper foil in-situ grown copper sulfide negative electrode material prepared by the invention is ap...

Embodiment 2

[0031] (1) Cut the 0.01 mm copper foil into 3×4 cm, put it in absolute ethanol, acetone, and deionized water for 3 minutes, and soak it in 1.0 M hydrochloric acid for 1 minute to obtain some polished copper foils;

[0032] (2) Add 1.5 M Na 2 S 9H 2 O was dissolved in 200 ml deionized water to obtain solution A;

[0033] (3) Adjust the three-constant reaction apparatus so that the reaction time is 10 min. The graphite sheet is used as the cathode, the high-purity copper foil is used as the anode, the solution A is the electrolyte, the reaction current is 30 mA, and the copper after the reaction is washed repeatedly with deionized water. foil and blown dry with nitrogen to obtain a product A with a black active substance attached to the copper foil;

[0034] (4) The product A was placed in argon at 200 °C, annealed for 1 h to 200 °C and kept for 2 h to obtain product B with copper sulfide attached.

[0035] The battery copper foil in-situ grown copper sulfide negative electro...

Embodiment 3

[0038] (1) Cut the 0.01 mm copper foil into 3×4 cm, put it in absolute ethanol, acetone, and deionized water for 3 minutes, and then soak it in 1.0 M hydrochloric acid for 5 minutes to obtain some polished copper foils;

[0039] (2) Add 1.0 M Na 2 S 9H 2 O was dissolved in 200 ml deionized water to obtain solution A;

[0040] (3) Adjust the three-constant reaction apparatus so that the reaction time is 20 min. The graphite sheet is used as the cathode, the high-purity copper foil is used as the anode, the solution A is the electrolyte, and the reaction current is 20 mA. The copper after the reaction is repeatedly washed with deionized water foil and blown dry with nitrogen to obtain a product A with a black active substance attached to the copper foil;

[0041] (4) The product A was placed in argon at 200 °C, annealed for 1 h to 200 °C and kept for 2 h to obtain product B with copper sulfide attached.

[0042] The battery copper foil in-situ grown copper sulfide negative el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com