Lithium negative electrode pretreatment protection agent, lithium negative electrode pretreatment protection method and lithium negative electrode with protective layer

A lithium negative electrode and pretreatment technology, which is applied in the field of lithium negative electrodes, can solve problems such as impact, not found, and specific capacity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A lithium negative electrode pretreatment protection method, comprising the following steps:

[0072] S10. In a drying room, 1kg of propylsulfonyl fluoride (A) is rectified through a rectifying column for 12 hours to dry and remove water to obtain dry propylsulfonyl fluoride, and then dry propylsulfonyl fluoride and perfluorobutylmethane The ether is stirred and mixed at a mass ratio of 70:30 to form a uniform mixed solution as the lithium negative electrode pretreatment protective agent in Example 1;

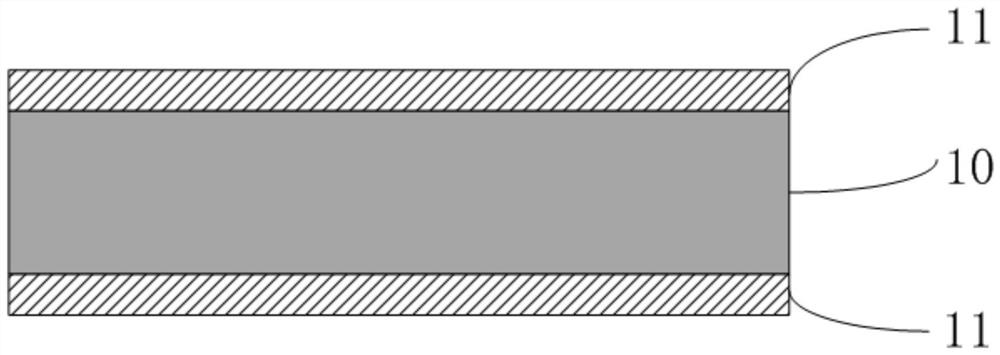

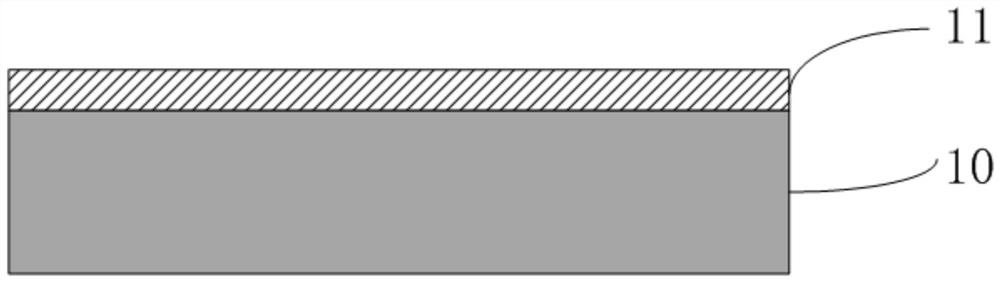

[0073] S20. In an argon-filled glove box, the lithium negative electrode pretreatment protective agent of Example 1 is coated on the surface of the unprotected metal lithium negative electrode by brushing, and the brushing time is 20 minutes. Chemical reaction, a protective layer with a thickness of 50 nm is formed in situ on the surface of the metal lithium negative electrode to obtain a lithium negative electrode with a protective layer, the protective layer includes l...

Embodiment 2

[0075] A lithium negative electrode pretreatment protection method, comprising the following steps:

[0076] S10. In an argon-filled glove box, add 100 g of perfluorobutylsulfonyl fluoride (C) liquid The molecular sieve was left to stand for 10 hours to dry to remove water, and filtered to obtain a dry perfluorobutylsulfonyl fluoride liquid as the lithium negative electrode pretreatment protective agent in Example 2;

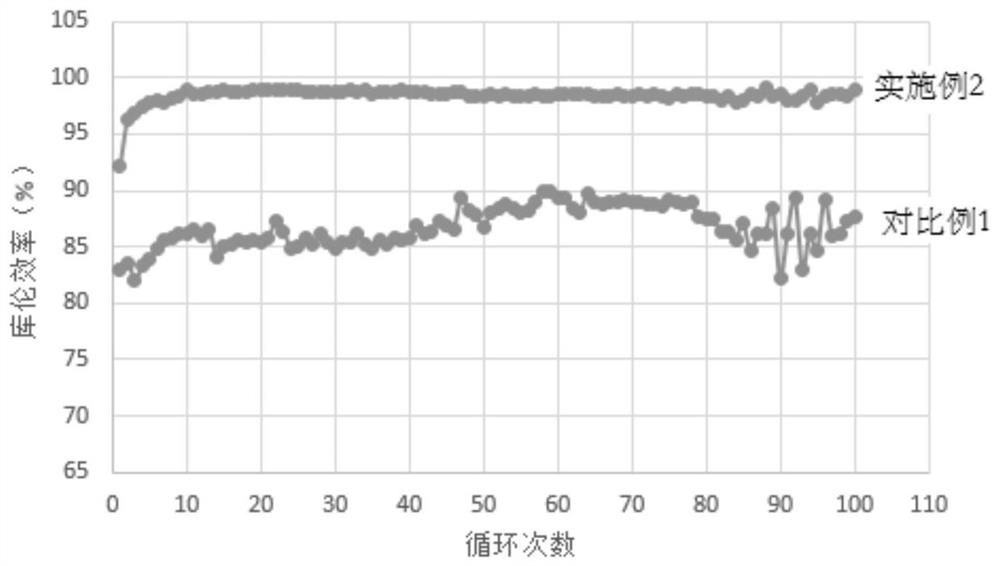

[0077] S20, in an argon-filled glove box, soak the unprotected metal lithium negative electrode in the lithium negative electrode pretreatment protective agent of Example 2, the soaking time is 10min, and the perfluorobutylsulfonyl fluoride chemically reacts with the metal lithium. A protective layer with a thickness of 20 nm is formed in situ on the surface of the metal lithium negative electrode to obtain a lithium negative electrode with a protective layer, the protective layer includes lithium fluoride and a sulfur-containing compound, and the sulfur-contai...

Embodiment 3

[0079] A lithium negative electrode pretreatment protection method, comprising the following steps:

[0080] S10. In an argon-filled glove box, add 100 g of p-benzenesulfonyl fluoride (F) liquid The molecular sieve was left to stand for 10 hours to dry to remove water, filtered to obtain a dry p-benzenesulfonyl fluoride liquid, and then the dry p-benzenesulfonyl fluoride and 1,2-dimethoxyethane were stirred and mixed in a mass ratio of 80:20 to form a uniform The mixed solution is used as the lithium negative electrode pretreatment protective agent in Example 3;

[0081] S20, in an argon-filled glove box, the lithium negative electrode pretreatment protective agent of Example 3 was coated on the surface of the unprotected lithium aluminum alloy negative electrode by spin coating, and the spin coating time was 30 min, and the formation of p-benzenesulfonyl fluoride and lithium Chemical reaction, a protective layer with a thickness of 30nm is formed in situ on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com