Preparation method and application of high-resilience EPO polymer material

A technology of polymer materials and resilience, applied in the field of building waterproofing engineering, can solve problems affecting construction efficiency, insufficient flexibility, troublesome road transportation, etc., to improve construction application and transportation, improve rigidity and heat resistance, The effect of superior anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

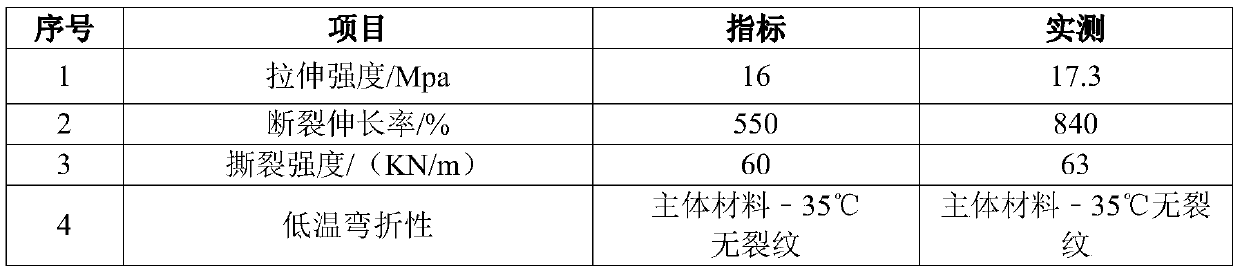

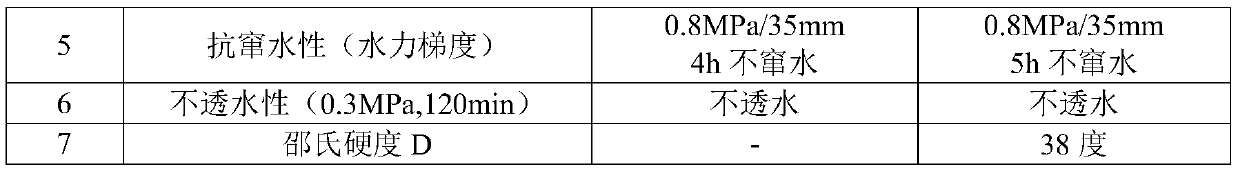

Examples

Embodiment 1

[0049] The present embodiment provides that high resilience EPO polymer comprises following raw material (weight fraction):

[0050] Toughening agent: polyolefin thermoplastic elastomer (POE), 55%;

[0051] Linear low density polyethylene: 7%;

[0052] Homopolymer PP: 20%;

[0053] Mineral filler: calcium carbonate masterbatch with a whiteness of 94, 10%;

[0054] Compatibilizer: maleic anhydride grafted polyethylene, 3%;

[0055] Modification additives: polyethylene wax: 1%, vinyl bis stearamide: 0.8%, white mother: 1%, white oil: 0.2%;

[0056] Antioxidant: tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythyl alcohol ester: 0.5%; tris(2,4-di-tert-butylphenyl) phosphite : 0.5%;

[0057] Anti-ultraviolet agent: 2-hydroxy-4-n-octyloxybenzophenone: 0.2%, bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate: 0.8%.

[0058] The high resilience EPO macromolecule raw material is passed through an attached figure 1 The steps given are to prepare EPO polymer wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com