Single-component polyurea coating and preparation method thereof

A single-component, polyurea technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of reducing the waterproof and anti-corrosion effect of products, affecting the physical properties of coating films, etc., and achieve excellent physical properties, bright colors, and weather resistance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Stir and mix polyether polyol, polyester polyol and pigments and fillers according to the parts by weight in Table 1.1, heat up to 120°C, and carry out vacuum dehydration for 2 hours under the condition of vacuum degree of -0.08Mpa;

[0034] After cooling down to 45°C, add 10 parts of liquefied MDI, heat up to 80°C and store for 2 hours;

[0035] According to the parts by weight in Table 1.2, add amine chain extenders and organic solvents, cool down to 60°C and store for 1 hour;

[0036] When the measured NCO group content is 2.8%, lower the temperature to below 45°C, add 2 parts of latent curing agent, keep stirring for 30 minutes, filter and discharge the material, and obtain the one-component polyurea coating A.

[0037] Table 1.1

[0038] Material parts by weight / part High activity polyether GEP330N 20 T-1136 special structure linear polyester polyol 10 Titanium dioxide 10

[0039] Table 1.2

[0040] contents parts by ...

Embodiment 2

[0042] Stir and mix polyether polyol, polyester polyol and pigments and fillers according to the parts by weight in Table 2.1, heat up to 120°C, and carry out vacuum dehydration for 2 hours under the condition of vacuum degree of -0.08Mpa;

[0043] After cooling down to 45°C, add 30 parts of liquefied MDI, heat up to 80°C and store for 2 hours;

[0044] According to the parts by weight in Table 2.2, add amine chain extenders and organic solvents, cool down to 60°C and store for 1 hour;

[0045] When the NCO group content was measured to be 2.8%, the temperature was lowered to below 45°C, 6 parts of latent curing agent was added, and after 30 minutes of heat preservation and stirring, the material was filtered and discharged to obtain a one-component polyurea coating B.

[0046] Table 2.1

[0047] Material parts by weight / part High activity polyether GEP551C 40 T-1136 special structure linear polyester polyol 20 carbon black 20

[0048] Table ...

Embodiment 3

[0051] Stir and mix polyether polyol, polyester polyol and pigments and fillers according to the parts by weight in Table 3.1, heat up to 120°C, and carry out vacuum dehydration for 2 hours under the condition of vacuum degree of -0.08Mpa;

[0052] After cooling down to 45°C, add 20 parts of liquefied MDI, heat up to 80°C and store for 2 hours;

[0053] According to the parts by weight in Table 3.2, add amine chain extender and organic solvent, cool down to 60°C and store for 1 hour;

[0054] When the measured NCO group content is 2.8%, lower the temperature to below 45°C, add 3 parts of latent curing agent, keep warm and stir for 30 minutes, then filter and discharge to obtain one-component polyurea coating C.

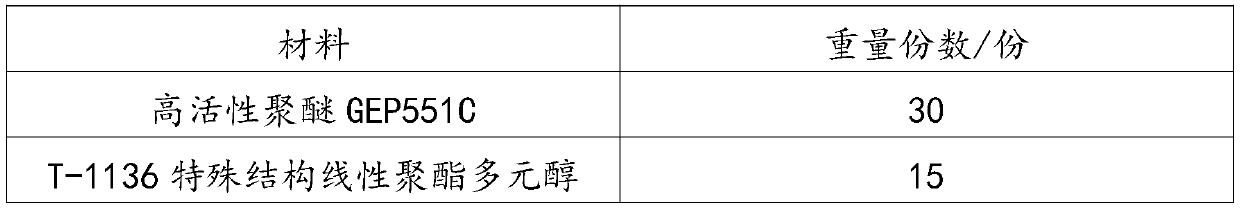

[0055] chart 3.1

[0056] Material parts by weight / part High activity polyether GEP330N 30 T-1136 special structure linear polyester polyol 15 big red powder 15

[0057] Table 3.2

[0058] contents parts by weight / part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com