Chemical palladium plating reduction agent and chemical palladium plating solution

A reducing agent, chemical plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the coating flatness, poor brightness, chemical palladium reducing agent poisoning, stable palladium plating solution problems such as poor performance, to achieve the effect of smooth surface, simple components, and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of electroless palladium plating liquid of embodiment 1

[0038] Described electroless palladium plating liquid is made of following raw material:

[0039] Palladium chloride 0.1g / L, citric acid 5g / L, hexamethylenetetramine 1g / L, adjust the pH of the electroless palladium plating solution to 3.0 with hydrochloric acid, to obtain final product.

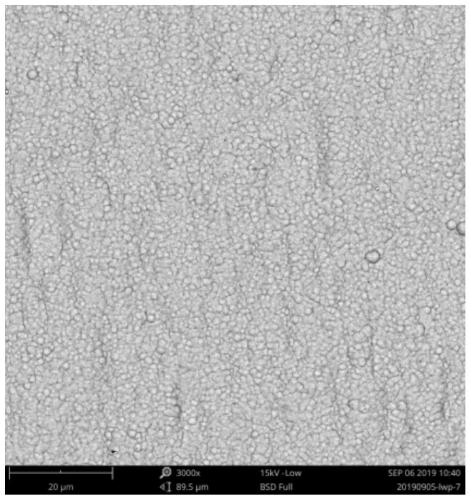

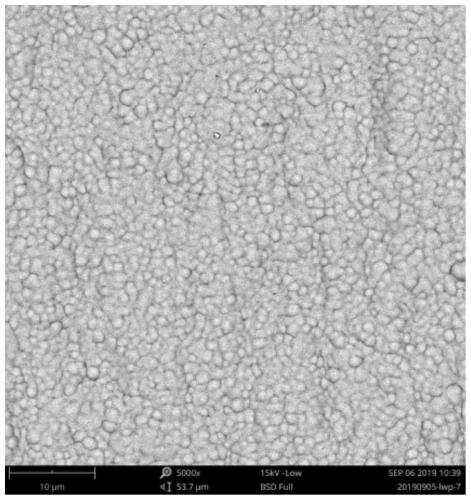

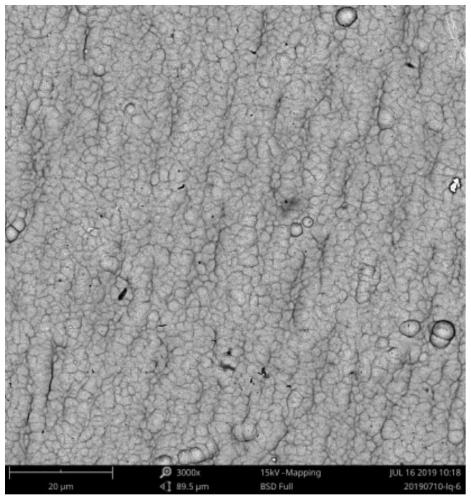

[0040] Plating a 10×10mm nickel-plated substrate in a plating solution at 55°C for 15 minutes, washing with water and drying after plating to obtain a palladium film with an average thickness of 0.05±0.02 μm; magnify the palladium film by 3000 under a scanning electron microscope Observed at magnification, it can be observed that the palladium film on the surface is smooth.

[0041] When the electroless palladium plating solution is cooled, its pH is measured to be 2.95.

[0042] After the electroless palladium plating solution of embodiment 1 was placed for 3 days, the plating solution had good stability, and the pheno...

Embodiment 2

[0043] A kind of electroless palladium plating liquid of embodiment 2

[0044] Described electroless palladium plating liquid is made of following raw material:

[0045] Palladium chloride 0.1g / L, citric acid 5g / L, lactose 2g / L, adjust the pH of the electroless palladium plating solution to 3.0 with hydrochloric acid, to obtain final product.

[0046] Plating a 10×10mm nickel-plated substrate in a plating solution at 55°C for 15 minutes, washing with water and drying after plating to obtain a palladium film with an average thickness of 0.06±0.02 μm; magnify the obtained palladium film under a scanning electron microscope at 3000 Observed at magnification, it can be observed that the palladium film on the surface is smooth.

[0047] When the electroless palladium plating solution is cooled, its pH is measured to be 2.85.

[0048] After the electroless palladium plating solution of embodiment 2 was placed for 3 days, the plating solution had good stability, and the phenomenon ...

Embodiment 3

[0049] A kind of electroless palladium plating solution of embodiment 3

[0050] Described electroless palladium plating liquid is made of following raw material:

[0051] Palladium chloride 0.5g / L, citric acid 20g / L, glucose 8g / L, the pH of the electroless palladium plating solution is adjusted to 3.0 with hydrochloric acid, to obtain final product.

[0052] Plating a 10×10mm nickel-plated substrate in a plating solution at 55°C for 15 minutes, washing and drying after plating, to obtain a palladium film with an average thickness of 0.18±0.02 μm; magnify the palladium film by 3000 under a scanning electron microscope Observed at magnification, it can be observed that the palladium film on the surface is smooth and bright.

[0053] When the electroless palladium plating solution is cooled, its pH is measured to be 2.96.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com