A kind of production process of APMP

A production process and wood chip technology, which is applied in the field of fabric bleaching, can solve the problems affecting the production efficiency of the workshop and the overall pulp supply output, and achieve the effect of solving the scaling problem of the main mill and the system, reducing consumption and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

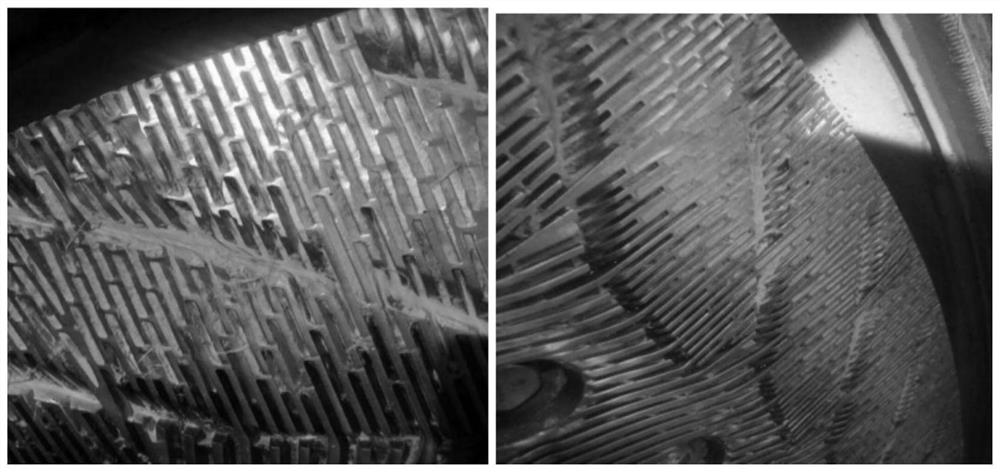

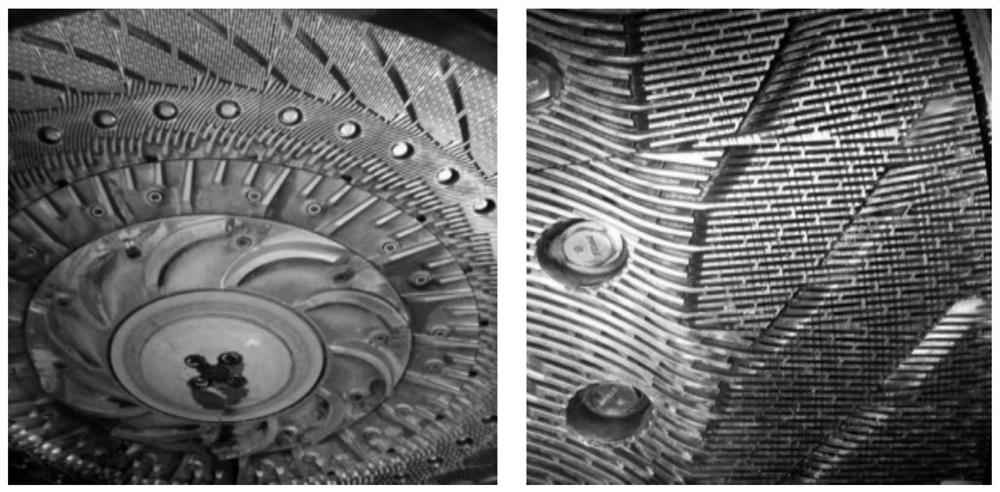

Image

Examples

Embodiment 1

[0023] A production process of APMP, using sodium polyhydroxyacrylate instead of sodium silicate, the raw materials are sequentially passed through the chip bin, belt conveyor, chip scrubber, chip mixing tank, chip pump, inclined dehydration screw, pre-steaming bin, 1#, 2#MSD, vertical prepreg, reaction chamber, 1#, 2# horizontal conveying screw, 1#, 2# plug feeding screw, 1# main mill, cyclone separator, PSD, cooling screw, bleaching tower, 1 #Medium Consistency Pump, 1#SCP, 1# Dilution Spiral, De-submergence Pool, 1#, 2# Low Consistency Mill, Intermediate Slurry Tank, 1#, 2#F50 Pressure Screen, Multi-Disc Thickener, 3# Medium Consistency The pump reaches the slurry tower; the waste liquid generated in the production process is dried by the evaporator, and the remaining concentrated waste liquid is sent to the alkali recovery for treatment.

[0024] Add sodium polyhydroxyacrylate to 1#MSD, 2#MSD and bleaching tower respectively, the dosage ratio is 1.5:1.5::4, the total dosag...

Embodiment 2

[0032] 1. Development of wood flour:

[0033] The chemical-mechanical slurry field takes old poplar wood, puts it in a wood powder grinder and grinds it into wood powder, and measures the dryness of the wood powder.

[0034] 2. Application experiment

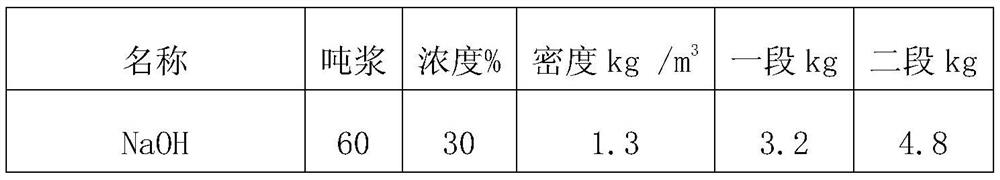

[0035] 1) Take 40g of absolute dry wood powder, put it in a strong thick plastic bag, do the first dosing, add according to 40% of the total dosage, prepare the dilution water first, add caustic soda, chelating agent, penetrating agent, 1 #Add sodium silicate, 2#, 3# respectively add 4kg / t and 6kg / t sodium polyhydroxyacrylate, mix evenly and add to the plastic bag together. Adjust the slurry concentration to 28%, knead repeatedly evenly, add hydrogen peroxide, and knead repeatedly evenly.

[0036] 2) Put the kneaded above-mentioned slurries in the pre-prepared water bath, and set the heat preservation temperature at 92°C to ensure that all the slurries in the bag are immersed in the water. The reaction time after the first stage...

Embodiment 3

[0050] In the production process, the output is controlled at about 115-120admt / shift, and the raw material is 100% new poplar wood, and the whiteness standard of the pulp is 75.0-77.0%. The original process uses sodium silicate (5kg / admt in the presoaking section + 18kg / admt in the bleaching section), and the addition amount is 23kg / admt. The current addition of sodium polyhydroxyacrylate is 7kg / admt (prepreg section 3kg / admt+bleach section 4kg / admt).

[0051] 1. The consumption of hydrogen peroxide is shown in Table 3 (random data testing for workshop application)

[0052] table 3

[0053]

[0054]

[0055] It can be seen from the above table that after using sodium polyhydroxyacrylate, the amount of hydrogen peroxide has increased to a certain extent, but the whiteness of the pulp has not decreased, which shows that sodium polyhydroxyacrylate has a good role in promoting the bleaching of hydrogen peroxide .

[0056] 2. System refresh cycle

[0057] From January to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com