A three-dimensional silicon-carbon composite negative electrode material and its preparation method and application in lithium-ion batteries

A silicon-carbon composite and negative electrode material technology, which is applied in the preparation/purification of carbon, negative electrodes, battery electrodes, etc., can solve the problems of battery first-time efficiency drop, small shaping strain, capacity attenuation, etc., and achieve a simple and efficient preparation method. Good plastic strain, improve the effect of mass specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

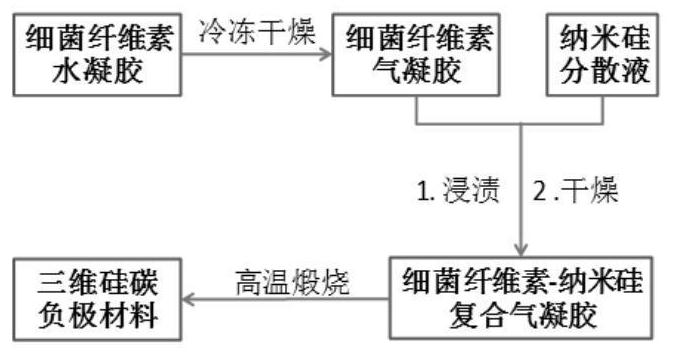

[0028] The preparation method of the three-dimensional silicon-carbon composite negative electrode material of the present invention, such as figure 1 As shown, the specific steps are as follows:

[0029] Step 1. The bacterial cellulose hydrogel is obtained by freeze-drying to obtain an aerogel, and then it is soaked in the nano-silicon source dispersion liquid. The mass concentration of the nano-silicon source dispersion liquid is 1-20%. Liquid nitrogen freeze-drying or supercritical drying to obtain bacterial cellulose / nano-silicon composite airgel;

[0030] Step 2. Pyrolyze the bacterial cellulose / nano-silicon composite airgel obtained in step 1 under an inert atmosphere at a temperature of 700-1200° C. for 0.5-3 hours, and naturally cool to obtain the three-dimensional silicon-carbon composite negative electrode material .

[0031] Nano-silicon source dispersion liquid is obtained by adding one or two mixtures of nano-element silicon powder and nano-silicon oxide powder ...

Embodiment 1

[0034] 1) Cut the bacterial cellulose hydrogel into rectangles (4*2*0.2cm 3 ), and then freeze-dried with liquid nitrogen to obtain bacterial cellulose airgel; add 10 mg of elemental silicon powder with an average particle size of 50 nm into 190 mg of deionized water, fully stir and ultrasonically disperse for 30 min by an ultrasonic breaker to obtain a stable mass concentration 5% nano-silicon source dispersion;

[0035] 2) Immerse the bacterial cellulose airgel in the nano-silicon source dispersion liquid for 30 minutes, rinse off the residual liquid on the surface with deionized water after taking it out, and then freeze-dry it with liquid nitrogen to obtain the bacterial cellulose / nano-silicon composite airgel;

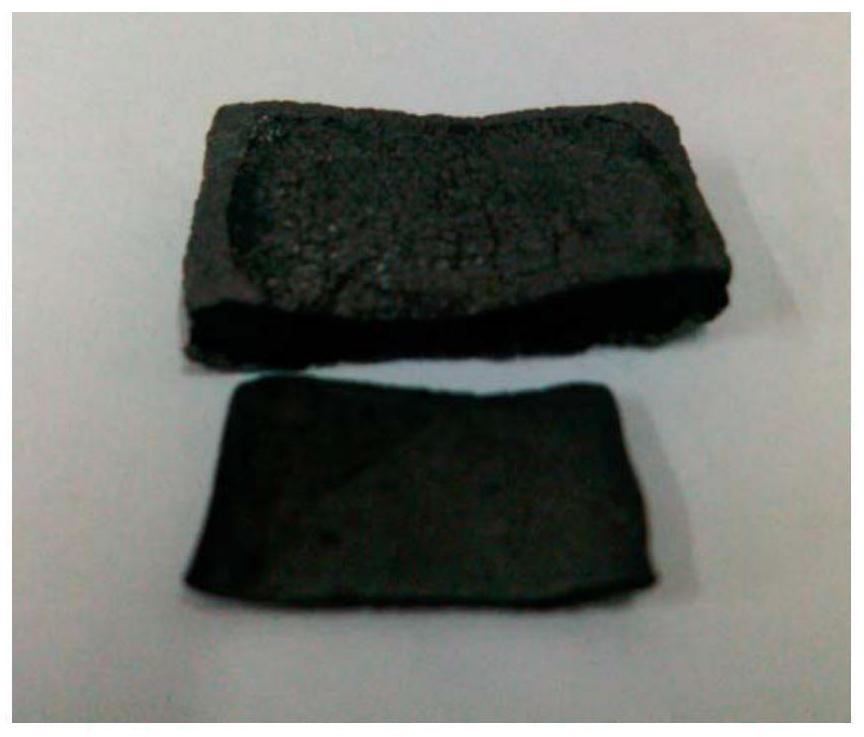

[0036] 3) The bacterial cellulose / nano-silicon composite airgel obtained in step 2 was pyrolyzed at 700° C. for 1 h under nitrogen atmosphere, and then cooled naturally to obtain a three-dimensional silicon-carbon composite negative electrode material.

[0037] S...

Embodiment 2

[0039] 1) Cut the bacterial cellulose hydrogel into rectangles (4*3*1.5cm 3 ), and then freeze-dried with liquid nitrogen to obtain bacterial cellulose airgel; add 30 mg of elemental silicon powder with an average particle size of 80 nm into 270 mg of absolute ethanol, fully stir and ultrasonically disperse for 30 min by an ultrasonic breaker to obtain a stable quality 10% nano-silicon source dispersion;

[0040] 2) Immerse the bacterial cellulose airgel in the nano-silicon source dispersion for 30 minutes, rinse off the residual liquid on the surface with ethanol after taking it out, and then dry it by supercritical to obtain the bacterial cellulose / nano-silicon composite airgel;

[0041] 3) The bacterial cellulose / nano-silicon composite airgel obtained in step 2 was pyrolyzed at 800° C. for 2 hours under an argon atmosphere, and cooled naturally to obtain a three-dimensional silicon-carbon composite negative electrode material.

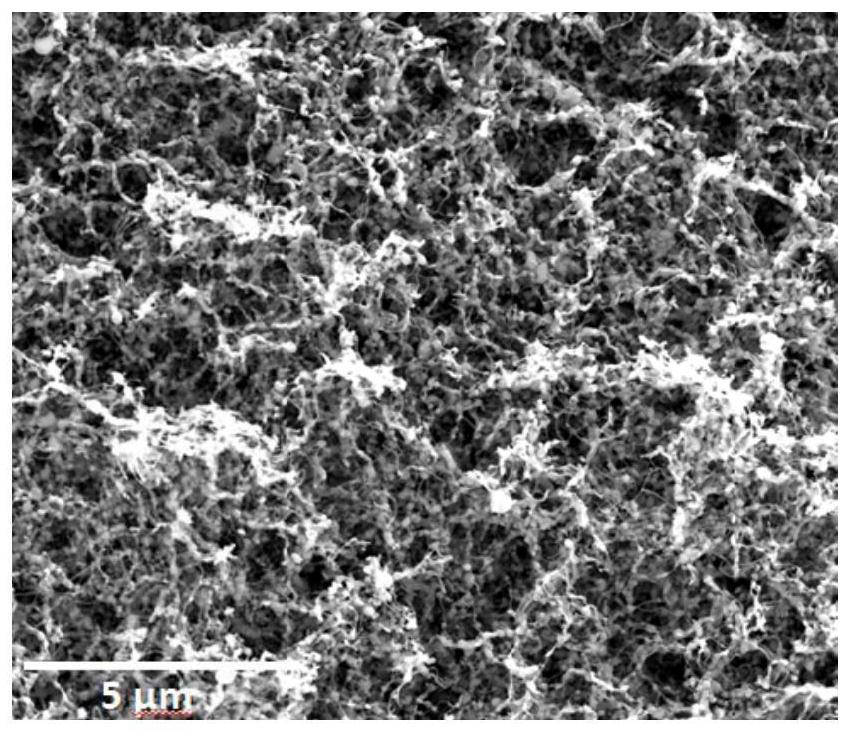

[0042] Such as Figure 4 As shown, the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com