Method for preparing isononanoic acid from mixed isooctene

A technology of isononanoic acid and octene, applied in the field of isononanoic acid preparation, can solve the problems of isononanoic acid yield and low selectivity, achieve high selectivity, realize large-scale continuous industrial production, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

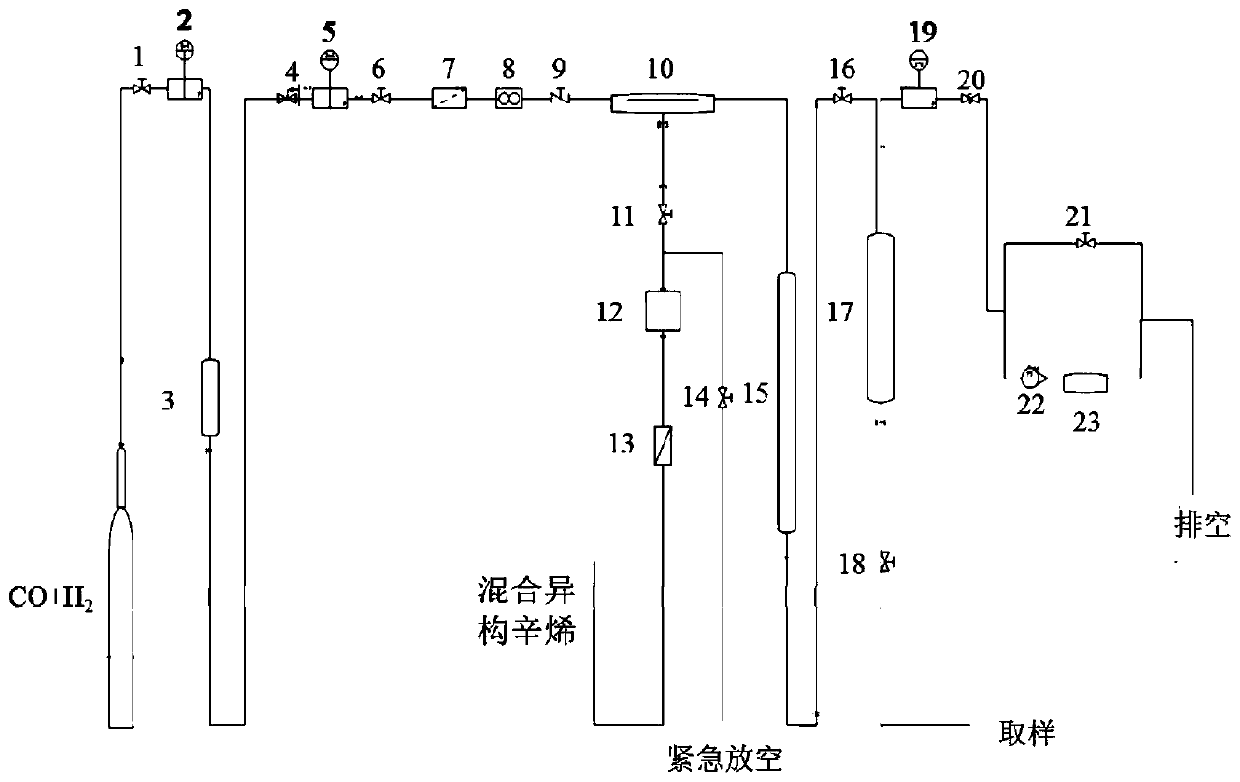

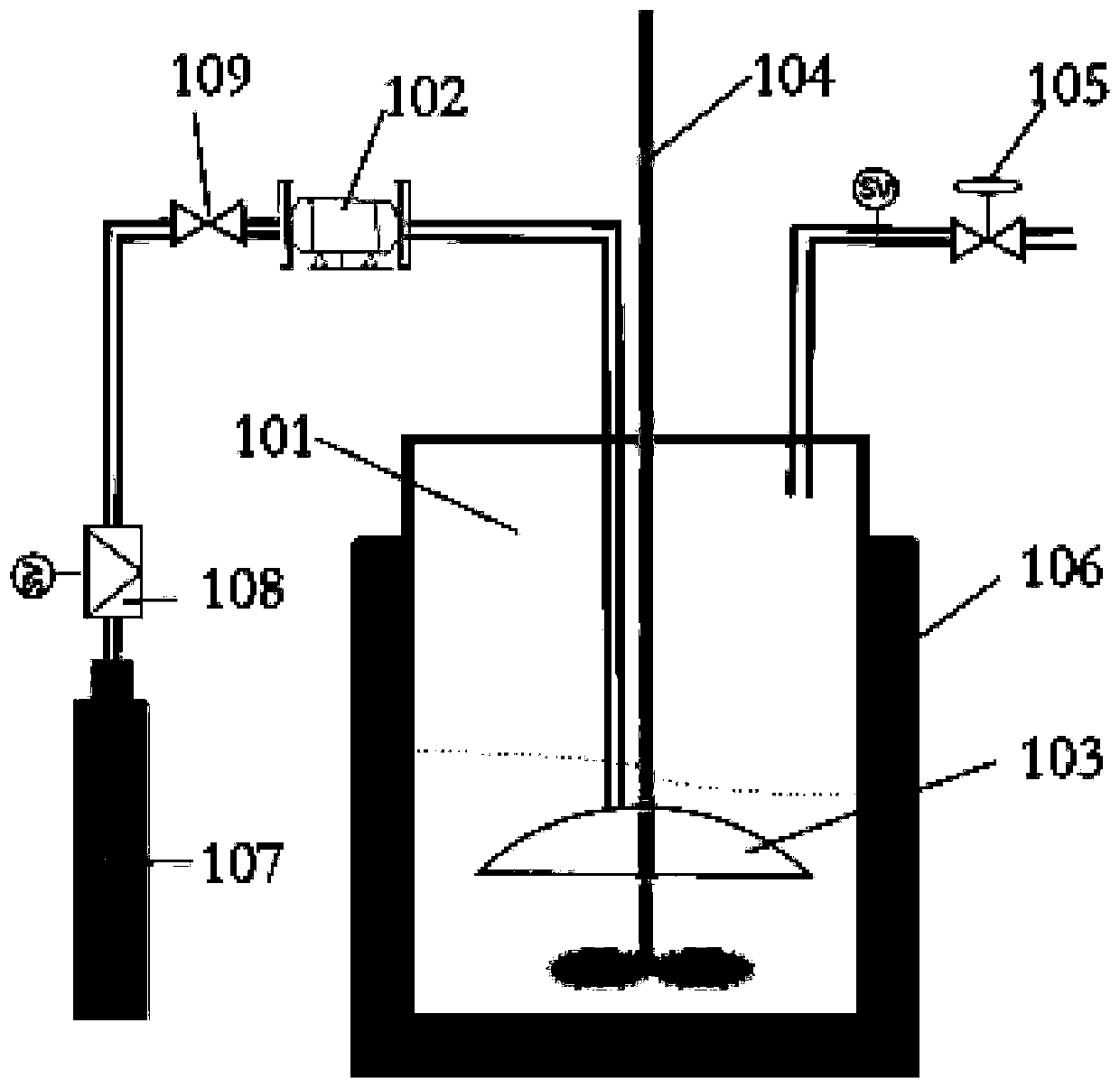

Method used

Image

Examples

preparation example Construction

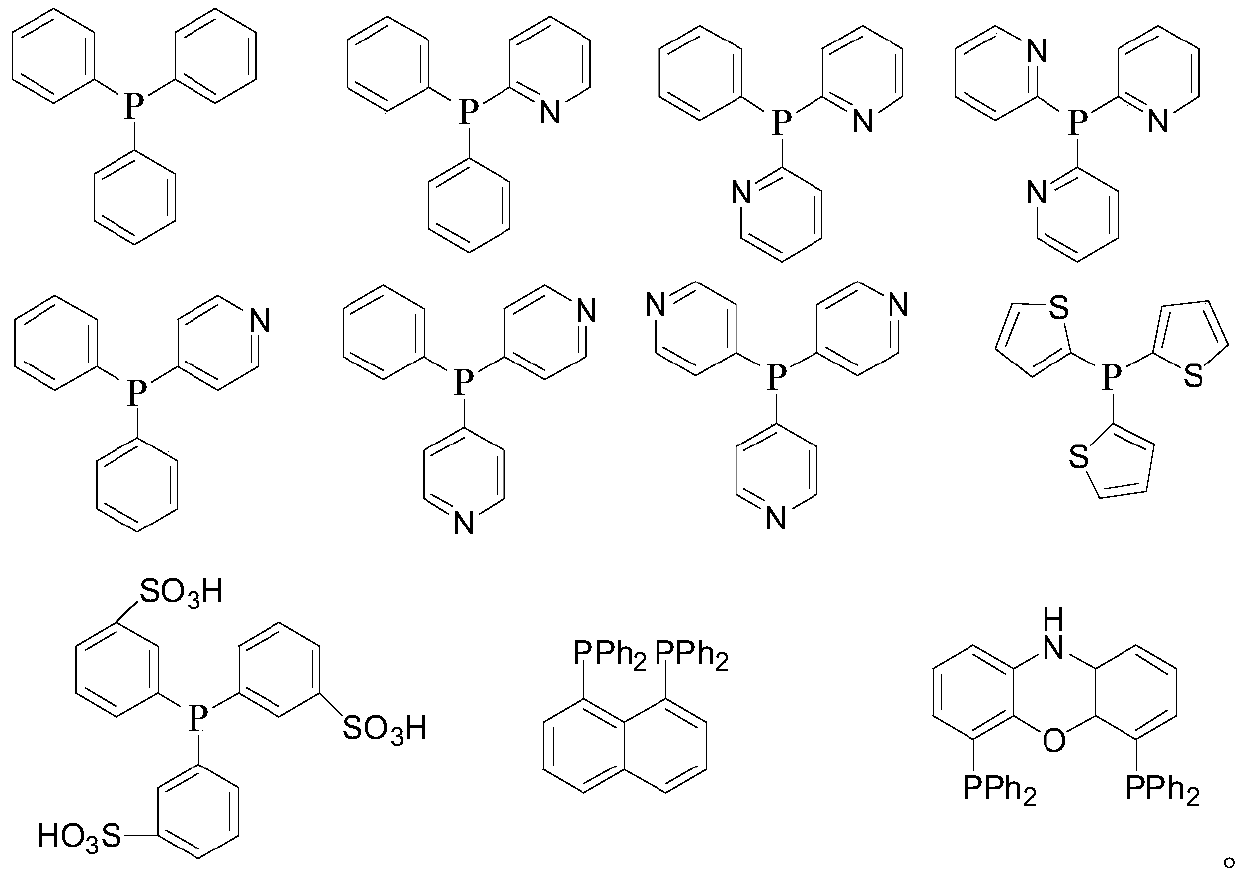

[0042] The preparation of porous organic polymer can refer to patent CN104710288B. The Rh-based catalyst supported by the porous organic polymer is prepared by an impregnation method or / and an ultrasonic method well known in the art.

[0043] Ultrasonic preparation can use the following steps:

[0044] (1) Dissolve the rhodium precursor in an anhydrous ethanol reagent to form a solution with a rhodium ion concentration of 0.0001 to 1mol / L; the rhodium precursor is rhodium nitrate, rhodium phosphate, rhodium trichloride, rhodium acetylacetonate, and rhodium carbonyl One or more of phenyl rhodium, etc.;

[0045] (2) Take a certain amount of porous organic polymer and add it to the solution obtained in step (1), and stir to obtain a mixed solution;

[0046] (3) Place the mixed solution obtained in step (2) in an ultrasonic instrument, and perform ultrasonic treatment for 5 to 200 minutes;

[0047] (4), filter the mixed solution after ultrasonic treatment in step (3), add ethan...

Embodiment 1

[0062] Weigh 1.0 g (about 1.5 mL) of the above-mentioned catalyst 5Rh / POP catalyst with a loading capacity of 5‰, and put it into the constant temperature zone of the fixed-bed reactor. First, synthesis gas was introduced into the reaction system, and after purging for 10 minutes, the temperature was raised to 100°C at a rate of 10°C / min, and the pressure was increased to 3.0MPa, waiting for the system to stabilize. Then the mixed iso-octene is injected into the mixer through a high-pressure pump, and the weight hourly space velocity of the mixed iso-octene is adjusted to be 0.02g 混合异构辛烯 / g 催化剂 h, the gas space velocity of the synthesis gas in the reaction system is 1500mL 合成气 / mL 催化剂 · h, react, the reaction time is 60h, the tail gas is analyzed by online gas chromatography, and the liquid product is sampled from the collection tank and analyzed by online gas chromatography. The hydroformylation reaction of mixed isomeric octene has a conversion rate of 96.5% and a selecti...

Embodiment 2

[0064] Weigh 1.0 g (about 1.5 mL) of the above-mentioned catalyst 5Rh / POP catalyst with a loading capacity of 5‰, and put it into the constant temperature zone of the fixed-bed reactor. First, synthesis gas was introduced into the reaction system, and after purging for 10 minutes, the temperature was raised to 100°C at a rate of 10°C / min, and the pressure was increased to 3.0MPa, waiting for the system to stabilize. Then the mixed iso-octene is injected into the mixer through a high-pressure pump, and the weight hourly space velocity of the mixed iso-octene is adjusted to be 0.02g 混合异构辛烯 / g 催化剂 h, the gas space velocity of the synthesis gas in the reaction system is 1500mL 合成气 / mL 催化剂 · h, react, the reaction time is 1000h, the tail gas is analyzed by online gas chromatography, and the liquid product is sampled from the collection tank and analyzed by online gas chromatography. In the hydroformylation reaction of mixed isomeric octene, the conversion rate is maintained abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com