Preparation method and application of carbon nanospheres

A nano-carbon ball, hydrolysis reaction technology, applied in nano-carbon, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of difficulty in forming uniform particle size, no system, economical and effective, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

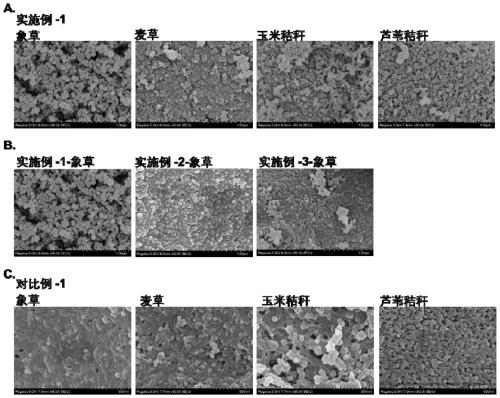

Embodiment 1

[0037] A preparation method of nano carbon spheres, comprising the steps of:

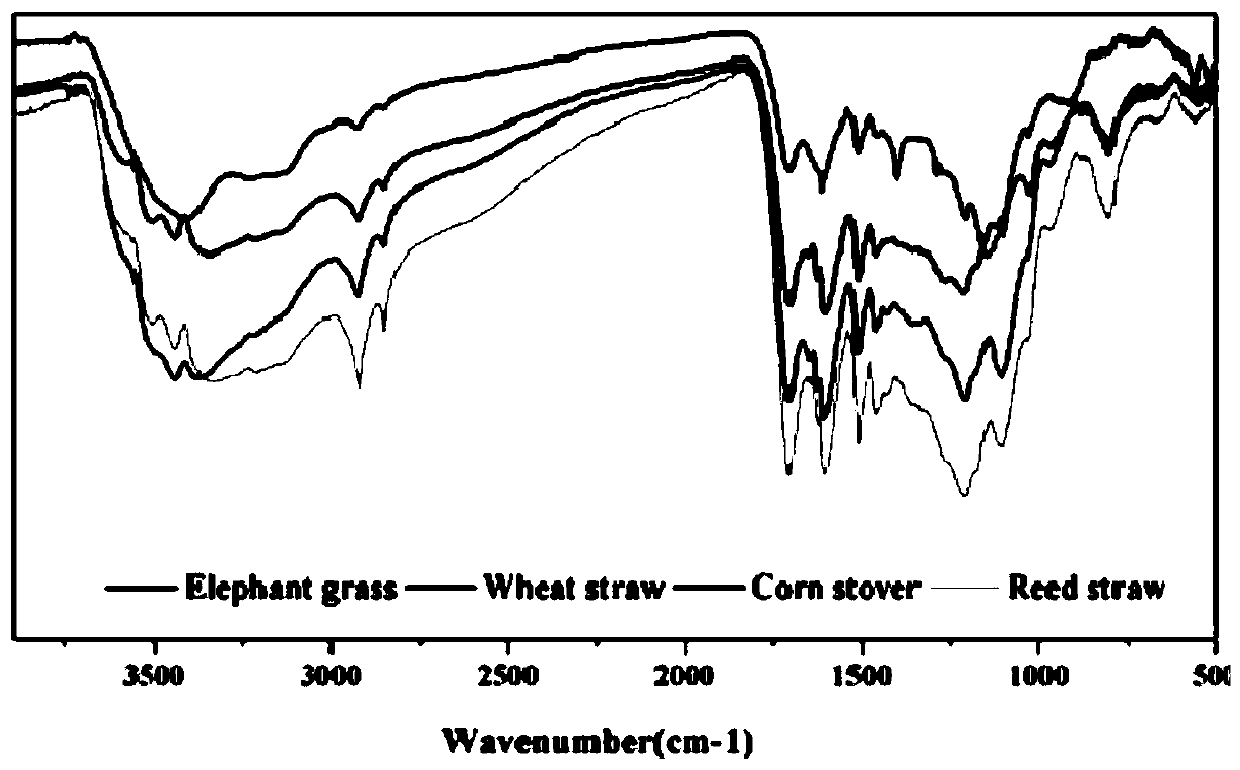

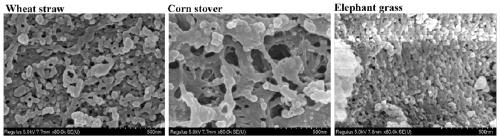

[0038] Ordinary commercial straws, the straws are elephant grass, reed straws, wheat straws and corn straws, which are processed separately. The treatment conditions are: drying in an oven at 40°C, then pulverizing with a pulverizer and passing through a 20-mesh sieve to prepare into powder; the powder is uniformly mixed with LiBr-HCl solution to prepare a mixture, the molar concentration of HCl in the LiBr-HCl solution is 0.5M, and the mixture includes components as powder by weight ratio: LiBr: water=5 :57:38, add the mixture into the pressure melting bomb, put the pressure melting bomb into the oven, control the heating rate to 2°C / min, heat up to the reaction temperature of 140°C, keep the temperature constant for 150min, and then cool down to 50°C ℃, take the pressure bomb out of the oven, and wait until the temperature drops to room temperature; use a sand core funnel to separate the solid fro...

Embodiment 2

[0040] A preparation method of nano carbon spheres, comprising the steps of:

[0041] Ordinary commercial straws, the straws are elephant grass, reed straws, wheat straws and corn straws, which are processed separately. The treatment conditions are: drying in an oven at 40°C, then pulverizing with a pulverizer and passing through a 20-mesh sieve to prepare into powder; the powder is uniformly mixed with LiBr-HCl solution to prepare a mixture, the molar concentration of HCl in the LiBr-HCl solution is 0.5M, and the mixture includes components as powder by weight: LiBr: water=10 :54:36, add the mixture into the pressure melting bomb, put the pressure melting bomb into the oven, control the heating rate to 2°C / min, heat up to the reaction temperature of 120°C, keep the temperature for 90min, and then cool down to 50°C, take the pressure melting bomb out of the oven, and wait until the temperature drops to room temperature; use a sand core funnel to separate the solid from the rea...

Embodiment 3

[0043] A preparation method of nano carbon spheres, comprising the steps of:

[0044]Ordinary commercial straws, the straws are elephant grass, reed straws, wheat straws and corn straws, which are processed separately. The treatment conditions are: drying in an oven at 40°C, then pulverizing with a pulverizer and passing through a 20-mesh sieve to prepare into powder; the powder is uniformly mixed with LiBr-HCl solution to prepare a mixture, the molar concentration of HCl in the LiBr-HCl solution is 0.5M, and the mixture includes components as powder by weight: LiBr: water=20 :48:32, add the mixture into the pressure melting bomb, put the pressure melting bomb into the oven, control the heating rate to 2°C / min, heat up to the reaction temperature of 140°C, keep the temperature for 120min, and then cool down to 50°C, take the pressure melting bomb out of the oven, and wait until the temperature drops to room temperature; use a sand core funnel to separate the solid from the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com