Acetone gas sensitive material and preparation method thereof

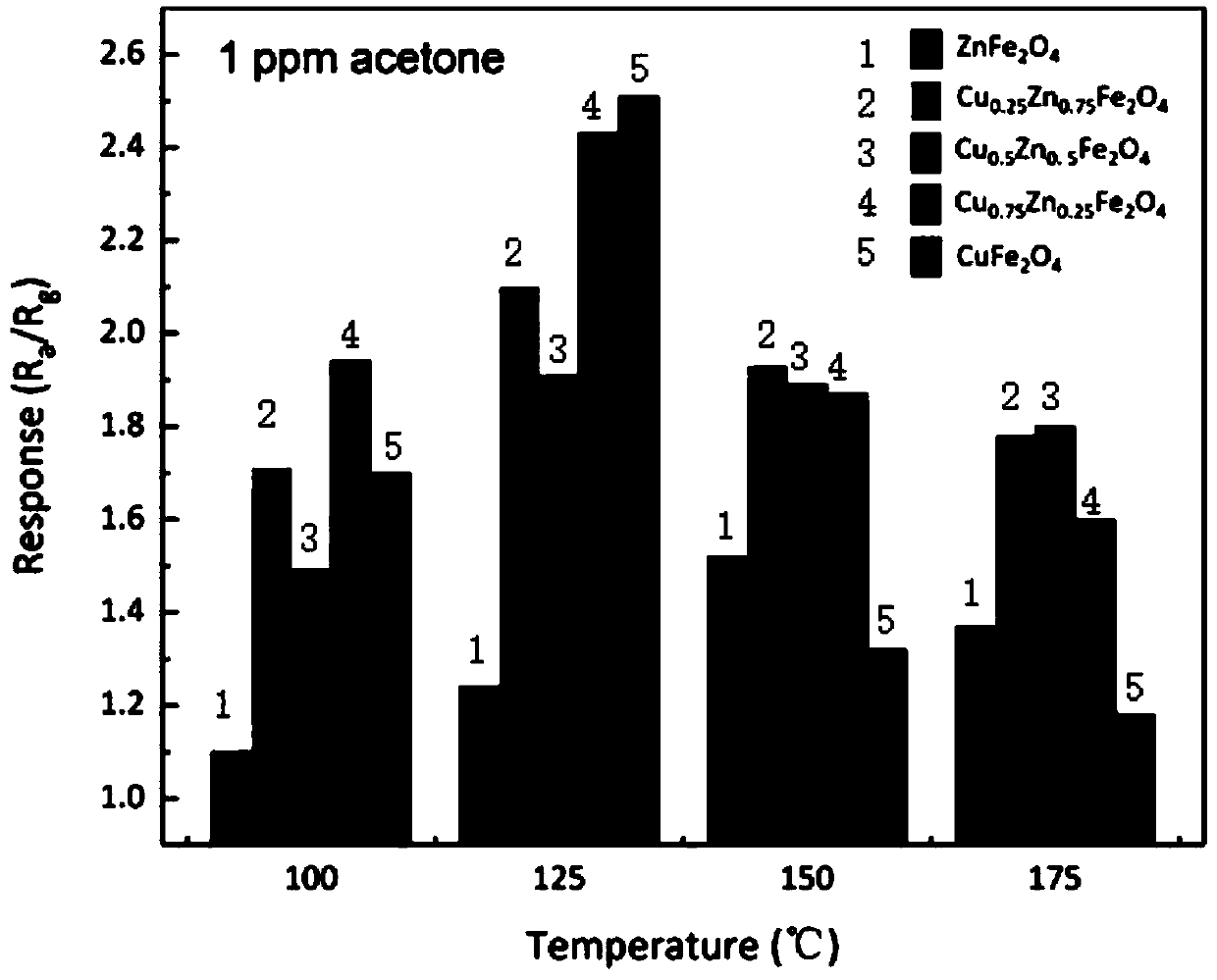

A technology of acetone gas-sensing and gas-sensing materials, which is applied in the fields of analysis materials, material resistance, chemical instruments and methods, etc., can solve the problems of high detection limit, high working temperature, low sensitivity of acetone gas, etc., and achieves high sensitivity and low cost. , high selectivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of gas-sensitive material of the present invention, carry out as follows:

[0030] (1) Preparation of organic solvents. At room temperature, pour isopropanol (30 ml) and glycerol (8 ml) into a 250 ml beaker successively, and magnetically stir for a period of time to obtain a homogeneous organic solvent system.

[0031] (2) Preparation of the mixed solution. At room temperature, Cu(CH 3 COO) 2 ·H 2 O, Zn(CH 3 COO) 2 2H 2 O and Fe(NO 3 ) 3 9H 2 The molar mass ratio of O is x mmol: 1-x mmol: 1 mmol (x=0.25, 0.5, 0.75, 1) and added to the organic solvent system in step (1) while stirring, and a uniform solution was obtained after magnetic stirring for a certain period of time.

[0032] (3) Autoclave reaction. Transfer the homogeneous solution in step (2) to a 100 ml polytetrafluoroethylene-lined stainless steel autoclave, seal it, and place it at 180 ° C for 12 h. After the reaction, it is naturally cooled to room temperature, centrifuged, ...

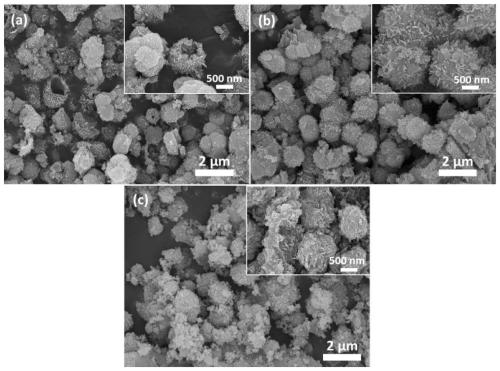

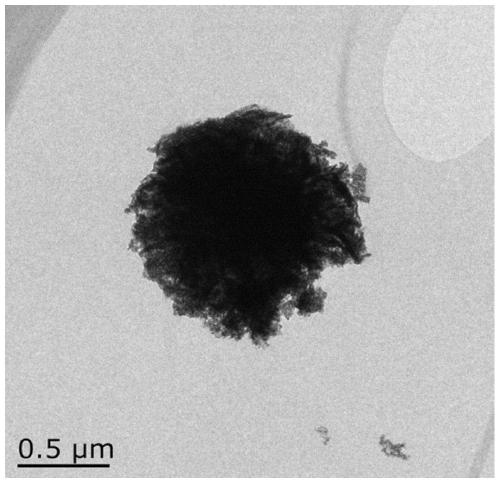

Embodiment 1

[0038] At room temperature, mix 8 ml of glycerin and 30 ml of isopropanol, and magnetically stir to obtain a homogeneous organic solvent. 0.125mmol Cu(CH 3 COO) 2 ·H 2 O, 0.375 mmol Zn(CH 3 COO) 2 2H 2 O and 1 mmol Fe(NO 3 ) 3 9H 2 O was added to the mixed solvent successively while stirring, and a uniform solution was obtained after stirring for a certain period of time. Then transfer it to a 100 ml polytetrafluoroethylene-lined stainless steel autoclave, seal it, and keep it at 180 °C for 12 h. After the reaction is completed, it is naturally cooled to room temperature, centrifuged, washed, and the product is heated at 60 °C. After drying for 12 h, the precursor material was obtained. Finally, the obtained precursor material was subjected to high-temperature heat treatment at a temperature of 400 °C, held for 2 h, and the heating rate was 4 °C / min, and then naturally cooled to room temperature to obtain a hollow structure Cu 0.25 Zn 0.75 Fe 2 o 4 gas sensitive m...

Embodiment 2

[0040] At room temperature, mix 8 ml of glycerin and 30 ml of isopropanol, and magnetically stir to obtain a homogeneous organic solvent. 0.25 mmolCu(CH 3 COO) 2 ·H 2 O, 0.25 mmol Zn(CH 3 COO) 2 2H 2 O and 1 mmol Fe(NO 3 ) 3 9H 2 O was added to the mixed solvent successively while stirring, and a uniform solution was obtained after stirring for a certain period of time. Then transfer it to a 100 ml polytetrafluoroethylene-lined stainless steel autoclave, seal it, and keep it at 180 °C for 12 h. After the reaction is completed, it is naturally cooled to room temperature, centrifuged, washed, and the product is heated at 60 °C. After drying for 12 h, the precursor material was obtained. Finally, the obtained precursor material was subjected to high-temperature heat treatment at a temperature of 400 °C, held for 2 h, and the heating rate was 4 °C / min, and then naturally cooled to room temperature to obtain a hollow structure Cu 0.5 Zn 0.5 Fe 2 o 4 gas sensitive mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com