Efficient and environment-friendly gold stripping powder and gold recovery process

A golden and environmentally friendly technology, applied in the direction of improving process efficiency, can solve the problems of complex process, large energy consumption, highly toxic cyanide liquid, etc., and achieve the effect of environmental protection of the recovery process, improvement of recovery rate and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment discloses a high-efficiency and environment-friendly gold removal powder. The gold removal powder is uniformly mixed with 30 g of gold beneficiation agent, 10 g of anti-staining salt S and 1 g of sodium dodecylbenzene sulfonate.

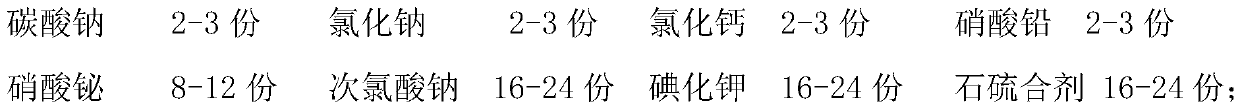

[0023] Among them, the gold beneficiation agent consists of 0.75g sodium carbonate, 0.75g sodium chloride, 0.75g calcium chloride, 0.75g lead nitrate, 3g bismuth nitrate, 3g ammonium nitrate, 3g potassium permanganate, 6g sodium hypochlorite, 6g potassium iodide and 6g Lime sulfur mixture is evenly mixed.

[0024] This embodiment also discloses a gold recovery process, comprising the steps of:

[0025] S1. Configure gold removal solution

[0026] Dissolve 41g of degolding powder in 1000mL of pure water at 45°C, stir evenly, put the metal to be degolded, soak for 4 minutes, remove the gold-plated layer on the metal surface, and form a degolding solution;

[0027] S2. Zinc wire replacement

[0028] Add 1mL of ammonia water and...

Embodiment 2

[0032] This embodiment discloses a high-efficiency and environment-friendly gold removal powder. The gold removal powder is uniformly mixed with 30 g of gold beneficiation agent, 10 g of anti-staining salt S and 1 g of sodium dodecylbenzene sulfonate.

[0033] Among them, the gold beneficiation agent consists of 0.7g sodium carbonate, 0.7g sodium chloride, 0.8g calcium chloride, 0.8g lead nitrate, 3g bismuth nitrate, 3g ammonium nitrate, 3g potassium permanganate, 6g sodium hypochlorite, 6g potassium iodide and 6g Lime sulfur mixture is evenly mixed.

[0034] This embodiment also discloses a gold recovery process, comprising the steps of:

[0035] S1. Configure gold removal solution

[0036] Dissolve 41g of degolding powder in 1000mL of pure water at 60°C, stir evenly, put in the metal to be degolded, soak for 4 minutes, remove the gold-plated layer on the metal surface, and form a degolding solution;

[0037] S2. Zinc wire replacement

[0038] Add 1mL of ammonia water and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com